-

ball mill technique parameter

Ball milling is a technique traditionally used in the metallurgy and mineral industries that aims to grind or blend powders [259]. The rigid balls, typically made of highhardness materials such as ceramics, flint pebbles, and stainless steels, collide with each other together with powders within a closed chamber.

Get Price -

Ball Milling Techinique

Ball Millfor Grinding Iron Ore Power Point File. Reducing grinding energy and cost grinding energy and cost magnetite iron ore design crushing followed by wet sag or ag milling and ball or pebble milling,.Reduces the power requirements compared to options 1 and milling can result in a very effective circuit from a capital and operating point of view.

Get Price -

Carbide Tools for Industry, Inc | Quality Carbide Tools ...

End Mills Ball Nose– 30° Helix Angle for Conventional Milling. 2 Flute End Mills for Soft Materials. 4 Flute End Mills for Steel. ... Mininum Purchase. EnterPromo Code: SAVE. SPEND OR MORE RECEIVE OFF. Burr Regrinding. Burr End Mill Reconditioning. Featured Products.

Get Price -

Basic End Mills Technical Information | MSC Industrial ...

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. Roughing end mills, also known as hog mills, are used to quickly remove large amounts of material during heavier operations.

Get Price -

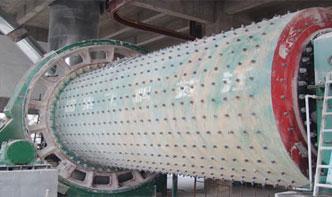

Ball Mill

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each appliion. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

Get Price -

Grind

Balls for use in mineral processing ball milling operations are designed for maximum abrasion resistance using high carbon content and high hardness levels. PRODUCT SPECIFICATIONS. SIZE Molycop manufactures forged grinding balls for use in ball milling and regrind appliions in nominal sizes from " to " in diameter.

Get Price -

Ball

Ball Corporation brings Ball Aluminum Cup™ to major retailers in all 50 states. The Ball Aluminum Cup™ will be available for the first time in more than 18,000 food, drug and mass retailers, including Kroger, Target, Albertsons, CVS and others.

Get Price -

ball milling techniques

ball milling techniques [randpic] Ball Milling an overview ScienceDirect Topics Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powd

Get Price -

We're working to become the best machining app on the market!

Surface Finish Calculators. Calculates lathe surface finish based on tool radius and feed. Calculate mill side wall finish based on tool diameter, cutting edges, and feed rate. Calculate step over distance of ball end mill based on your required surface finish. Convert Ra finish to other common surface finishes such as RMS, Rp, Rt.

Get Price -

Lowball

Lowball . Techniques > General Persuasion > Sequential Requests > Lowball. Description | Example | Discussion | See also . Description. First make what you want the other person to agree to easy to accept by making it quick, cheap, easy, etc. Maximize their buyin, in particular by getting both verbal and public commitment to this.

Get Price -

Ceramic Ball Mill For Grinding Materials

Ceramic ball mill is the typical grinding equipment which us ball mill ceramics, greatly improves the grinding fineness. Compared with the traditional ball mill, such kind of ball mill has a great advantage in function, structure, and operation. This machine also has great capacity, high technology, and no noise, which plays an important role ...

Get Price -

Home page | Midwest Circuit Technology

End Mills. Solid carbide end mills from .001" (.0254mm) to .125" (). All with 1/8" shank and " Overall Length, " available on request. Standard with plastic depth setting rings. Square end or Ball Nose for 3D work.

Get Price -

Calculate and Select Ball Mill Ball Size for Optimum Grinding

· In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize "just in case". Well, this safety factor can cost you much in recovery and/or mill liner wear and tear.

Get Price -

Ball Millling Technique

Ball milling is a technique traditionally used in the metallurgy and mineral industries that aims to grind or blend powders 259 the rigid balls typically made of highhardness materials such as ceramics flint pebbles and stainless steels collide with each other together with powders within a closed chamber.

Get Price -

This Position Reliably Gets Women Off | HuffPost Life

· The "coital alignment technique," aka , is a modified version of missionary, where the man rides a little higher, sliding his body up an inch or two so that the base of the penis rubs against the woman's clitoris.

Get Price -

Log and Tree Scaling Techniques FNR191

Log and Tree Scaling Techniques Daniel Cassens Purdue University Buying and selling logs and standing trees based on an estimate of the number of board feet they contain is an everyday practice in the lumber industry. However, it can also be a very confusing practice. There are a number of issues addressed in this publiion. In

Get Price -

OSG | Taps | End Mills | Drills | Indexable | Composite ...

BALL NOSE CORNER RADIUS TAPERED DOUBLE END ROUTERS BURS INDEXABLE FACE MILLING CUTTERS SHOULDER ... If you are looking for fractional or metric thread mills, straight or tapered mill for Pipe threads, your solution is here. Thread Milling Solutions. Inch

Get Price