-

Structural, Thermal and Electrical Properties of Nano ...

Nanoceramic filler was prepared by mechanical milling process for 48 hrs using the planetary ball mill. ... plasticizer (DBP) and manganese filler. These results clearly show that both the glass transition temperature (T g) and the melting temperature (T m) have decreased due to the addition .

Get Price -

ball mills for manganese ore

ball mills for manganese ore manganese ore price, manganese ore price Suppliers and Zinc Lead Ore Ball Mill Vertimill® 10000 1000 Microns 100 10 1 Mill Ty pe Typical Grinding Ranges Ball Mills and stirred mills are applied across a wide range of appliions, but for each ore there is optimum efficient range.

Get Price -

A Ball MillingEnabled CrossElectrophile Coupling

A Ball MillingEnabled CrossElectrophile Coupling ... frequently used in crosselectrophile coupling is manganese,3 Under the reaction conditions, the use of manganese pieces in the place of zinc maintained excellent reactivity affording the XEC product 3a in 78% yield.

Get Price -

TECHNICAL NOTES 8 GRINDING R. P. King

Figure Effect of mill filling on power draft for ball mills. The data is taken from Rexnord Process Machinery Reference Manual, Rexnord Process Machinery Division, Milwaukee, 1976 The effect of varying mill speed on the power drawn by the mill is shown graphically in Figure The speed of rotation of the mill influences the power draft through two effects: the value of N and the shift in ...

Get Price -

EFFECT OF PARTICLE FILLING AND SIZE ON THE BEHAVIOUR OF ...

that occur in mills when ore particles are being added to the ball load. This mimics the process of filling an industrial grinding mill after a grind out has been performed. Typically after a grind out, the mill operator would refill the mill with ore up to the point where maximum mill power draw is registered.

Get Price -

Kennametal® EADE Ceramic End Mills

HighPerformance Solid Carbide End Mills EADE • Solid Ceramic End Mills • KYS40™ Beyond™ Grade EADE • Solid Ceramic End Mills • KYS40™ Beyond™ Grade

Get Price -

Effects Of Various Elements In Manganese Steel Casting ...

· Different elements play different roles in high manganese steel casting parts. There are some effects of different elements: Effect Of "Carbon" Element Carbon is one of the two most important elements in manganese steels along with manganese. Manganese steels are a supersaturated solution of carbon. For most standard manganese steel grades the carbon and manganese.

Get Price -

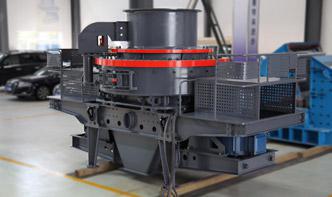

Industrial Ball Mills: Steel Ball Mills and Lined Ball ...

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800's. The basic construction of a ball mill is a cylindrical container with journals at its axis.

Get Price -

Ball Milling The Role of Media and Bead Mills

Ball milling is a grinding technique that uses media to effectively break down pigment agglomerates and aggregates to their primary particles. Using a rotor or disc impeller to create collisions of the grinding media, the impact and force created by the bead mills collisions break down the pigment agglomerates.

Get Price -

how to grind manganese ores using ball mill

Manganese ore powder grinding mill nickel ore powder mill supplier jeugdwerkindestadbeopper aluminum manganese nickel iron mining ball mill machine 1product appliion the ball mill is a key equipment to grind the crushed materials and the ball mill is widely used in powdermaking production line including cement silie newtype building material refractory ...

Get Price -

Food milling Equipment

Air classifying mills or jet mills can be suitable for ultrafine grinding and when you want to mill your foods to submicron levels we can help you with ball mill solutions. And when you are trying to reduce the particle size of a solid in suspension in a liquid, you may benefit from colloid or .

Get Price -

Synthesis of manganese–zinc ferrite by powder mixing using ...

· With the aim of producing finegrained manganese–zinc (Mn–Zn) ferrite at the end of a calcination process at moderate temperatures, this study consisted, at first, of an "electrochemically designed" powder mixing by wetball milling a mixture of manganese (MnO2), zinc (ZnO), and iron (Fe2O3 granules produced by an acid recovery unit of a Brazilian steelmaker, milled to fine sizes .

Get Price -

Ball Mill Loading

Charging a Wet Mill – The general operation of a grinding mill is to have the product impacted between the balls as they tumble. Unlike dry milling, wet milling is more straight forward and more forgiving in terms of charging the product. As with dry milling there should be at least 25% liquid to fill the void space plus a bit more to insure ...

Get Price -

filling degree ball mill

ball mill filling degree formula peperoncinostia formula to calculate filling of ball mill cmschool Ball mill A typical type of fine grinder is the ball slightly inclined or horizontal rotating cylinder is partially filled with balls usually stone or metal . Chat Online;

Get Price -

OPTIMIZATION OF THE BALL MILL PROCESSING PARAMETERS IN .

filling in a laboratory ball mill would imply the maximum agitator shaft speed and 30min milling time. Keywords: fat filling, ball mill milling variables, physical properties, sensory characteristics, optimization. Fat fillings contain high amount of fat (30–40%) which presents a continuous phase and determines the consistency of the filling.

Get Price -

Impact Load Behavior between Different Charge and Lifter ...

for the ball mills, while the power draw determined by DEM simulation show a good approximation for the measured power draw. Besides, the impact force on the lifter was affected by mill speed, grinding media filling, lifter height and iron ore particle. The maximum percent of the impact force between 600 and 1400 N is at 70–80% of critical speed. The impact force can be only above 1400 N at ...

Get Price -

Onepot mechanochemical ball milling synthesis of the MnOx ...

Here, we report on a onepot mechanochemical ball milling synthesis of manganese oxide nanostructures synthesized at different milling speeds. The assynthesized pure oxides and metal (Pt and Cu) doped oxides were tested in the hydrogenation of CO2 in the gas phase. Our study demonstrates the successful synt 2020 PCCP HOT Articles

Get Price -

mill ball filling

What is ball milling A ball mill is a type of grinder used to grind materials into extremely fine powder 7 How to Size a Ball Mill Design Calculator Formula B Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge causing the Total Charge Filling Level to be higher than the Ball Filling Level Grate Discharge mills will not face this issue

Get Price -

Mining | Replacement wear parts for crushers, sizers ...

Our jaw crusher wear parts include jaw plates, cheek plates, wedges cast in a workhardening manganese alloy for optimum performance. One client saw a wear life increase from days to 30 days with a Unicast titanium carbide jaw plate. From feed head to discharge end, our custommade liners optimize ball and SAG mill performance. Unicast engineers will provide a perfectfit design and alloy ...

Get Price -

manganese manganese crusher mills

Manganese Ore Grinding Mill Plant. It is grind manganese ore into different type of powder and has large capacity For a complete manganese ore processing plant, there also need small jaw crusher, elevator, powder collector machin Sometimes, manganese are needed in order to get high.

Get Price -

manganese grinding machine

China Gold Mining Machine Dry Cement Ball Mill China Dry . So using the manganese Steel Liners will make the ball mill wear resisting Picture3 Steel Balls They are the main medium for grinding the minerals in ball mill Picture4 Ball mill Motor and Reducer It will keep the ball mill rotating in a uniform speed 4 Ball Mill Grinding Working Principle

Get Price -

Used Ballmills For Sale

UNUSED FL 22' x 41'6" ( x ) Dual Pinion Regrind Ball Mill with 2 ABB 5,500 kW (7,375 HP) Drives for Total Power of 11,000 kW (14,750 HP) Manufacturer: FL. Inventory ID: 6CHM02. View Details.

Get Price -

EFFECT OF PARTICLE FILLING AND SIZE ON THE BEHAVIOUR OF ...

The probe's response to a load comprised of steel balls only at the fillings of 1545% and mill speeds of 60 – 105% indie that the various changes in load behaviour such as aracting, centrifuging, ball packing and toe and shoulder responses were easily distinguished in probes responses. Further tests were conducted in a mill with a 20% ball filling with increasing coarse or fine ...

Get Price -

optimum charge filling for manganese ball Mill

how to calculate volume in ballmill filling Mining . how to calculate volume in ballmill filling . BY admin This is usually performed soon after a crash stop. mill absorbed power and ball filling degree. optimum charge filling for manganese ball mill – Mining. simple ball mill filling level the chambers measured to calculate the ball charge, % filling and estimate

Get Price -

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL .

SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and The Built Environment, University of the Witwatersrand, ... Figure Variation of mill power draw with mill filling levels J (worn balls).123

Get Price