-

Beach Sand Mining Process | Equipment | Flow | Cases

The oregrade material is then loaded onto a truck using standard earthmoving equipment, where it then reports to a stockpile or a processing plant. A hydraulic dredge uses a suction pipe to excavate the sand, which is pumped through a pipeline to surge piles or directly to a processing plant.

Get Price -

iron ore washing plant

Mar 26, 2009 · This process has been proven on a number of ore washing installations throughout India and we have delivered increases in the Fe value from 54% to 62%, which brings considerable efficiencies in steel production. This process offers significant advantages not only for steel producers, but also for those involved in the trading of iron ore on the ...

Get Price -

What Is Involved in Pig Iron Production? (with pictures)

Jessica Ellis Iron ore is combined with charcoal in a blast furnace to create pig iron. The process of pig iron production involves the combination of iron ore, charcoal, and an intermediary material known as a flux inside a blast the materials combine with intense heat, much of the iron ore melts, creating a superheated, liquid form.

Get Price -

SciELO

In the steel production process, siliconmanganese iron slag has, among other things, the content of iron and calcium oxides, whose values are acceptable and therefore suitable to be used as railroad ballast, replacing the increasingly scarce and expensive natural materials.

Get Price -

Iron Extraction Process

Iron Extraction Process. In the blast furnace process, the first step on the way towards heavy plate, pig iron is produced from iron ore. The composition of the ore and additions is accurately adjusted to the final products of AG der Dillinger Hüttenwerke and Saarstahl AG.

Get Price -

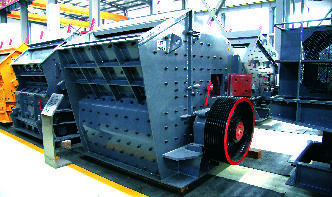

small impact crushers for ballast production

This jaw crusher is a perfect combination of modern science and technology and the production practice, which can better satisfy the automatic production demands of vast customers. Input Size: 0930mm Capacity: 12650TPH. Materials: Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore.

Get Price -

slag | MID RIVER MINERALS

The addition of limestone/dolomitic stone in its natural form or calcined form, to the iron and steel production process removes the majority of the gangue in the slag. SLAG is a broad term covering all non metallic co products resulting from the separation of a metal from its ore, Its chemistry and morphology depends on the metal being ...

Get Price -

used iron ore processing plant in russia

Used Iron Ore Processing Plant In Russia. nlmk plans mining, processing facility,nlmk plans mining, processing facility. russian producer novolipetsk has been given the government goahead for a 250 billion rouble (us billion) mining and processing facility at stoilensky iron ore project in western russia, near the ukrainian border. stoilensky already accounts for roughly 16% ...

Get Price -

Iron Ore | Geoscience Australia

Dec 31, 2018 · In 2018, Australia's EDR of iron ore increased by 3% from 2017 to 49 604 Mt (Table 3). Similarly, there was a 4% EDR increase of contained iron to 24 122 Mt (Table 4). EDR attributable to magnetite deposits have decreased by 1%, likely due to reassessment of projects and inactivity in the magnetite industry.

Get Price -

Track Ballast Production

Track Ballast Production. Tamping Machine Wikipedia. A tamping machine or ballast tamper is a machine used to pack or tamp the track ballast which have no points or other complex track structures, commonly referred to as production machines, generally have fixed tamping head positions.

Get Price -

Understanding US iron ore production | CRU

Nov 05, 2019 · In addition, the country has large iron ore deposits that have supported its steel industry for more than a century. Today, the USA is the world's fourth largest steel producing country, but what stands out is its high share of EAF production. In 2019, CRU estimates that 68% of the country's carbon crude steel output will be produced in the ...

Get Price -

Process for the production of iron

With the process for the production of iron from an ironoxygen combination, preferably ore, the ironoxygen combination is essentially reduced in an ore reduction vessel with a reaction gas from a melting crucible, then supplied to this melting crucible and melted by adding carboncontaining fuels and oxygencontaining gases.

Get Price -

PIG IRON PRODUCTION IS THE BASIS OF FERROUS METALLURGY ...

That is, iron oxide must be pure, without impurities, the same applies to carbon. And the air for blowing must consist of oxygen alone. Then the production of pig iron will go smoothly and according to the scheme described above. But in fact, iron ore contains a lot (more than 50%) of waste rock, which is mainly composed of silies.

Get Price -

Oremax

By introduction our customised process improvement package we will facilitate the processing of lower grade ores. By reducing your cutoff grade, we will deliver significant efficiencies to your ore processing operation. Maximise the recovery of minerals. Minimise wastage of water. Maximise the value of your minerals. Oremax Brochure.

Get Price -

Does hematite contain iron? –

Feb 11, 2020 · How do you process magnetite? A general processing circuit for magnetite ore is initial crushing and screening of run of mine (ROM) ore to <6 mm. The ore is then milled to a specified grind size to liberate the iron minerals from the gangue, then processed further to produce a magnetite concentrate, commonly by a wet magnetic separation process.

Get Price -

Iron ore facts

Key facts. In 2019, Canada was the eighth largest producer of iron ore in the world. The top five iron oreproducing countries accounted for % of global production. In 2019, world reserves of iron ore amounted to billion tonnes. The primary use of iron ore is to make steel, which is recyclable.

Get Price