-

Environmental Code of Practice for base metals smelters ...

In smelters and refineries, ores and concentrates are supplied from mines and mills, and recycled material is supplied for further recovery and purifiion of metals. This Code of Practice applies to both smelters and refineries of primary copper, primary and secondary lead, .

Get Price -

Orewinners and Deadmen: Lead Mining in Swaledale ...

· Men toiled underground, chimneys on the moortops spewed toxic gases from smelt mills, ponies pulled carts of metal ingots to market in Richmond, and the life of those in the dale was hard and poor. The main mineral being extracted from the hills was galena, which produces lead.

Get Price -

Smelting

In the north Pennines, the London Lead Company, in particular, had wide experience of the early use of cupolas for lead smelting. In 1705, it acquired the Ryton Smelting Company's cupola mill, near Newcastle upon Tyne, but the mill was abandoned in 1706 because savings in transport costs could be made if Whitfield smelt mill, which had orehearths and was nearer the mines, was leased instead.

Get Price -

Metallurgical Material Handling SolutionS

Top : 204 Sinter machine at Tata Steel, Jamshedpur. Middle Left: Hot Strip Mill at Jindal Steel, Bellary. Middle Right : Hot metal at cast house for Tata Steel. Bottom : Lead Smelter Plant for Hindustan Zinc Limited at Dariba. Top : ESSAR Sponge Iron Plant .

Get Price -

12 years of leaching of contaminants from Pb smelter slags ...

In contrast, Pb activity in soil waters in environments with predominant lead oxides due to weathering of metallic lead, at shooting ranges (Li et al. 2015), is most probably controlled by ...

Get Price -

The North Pennine Orefield

They were erected here at the ends of underground flues that carried noxious metalrich gases away from the valleybased smelting mills. Loion and structure of the orefield At 1,500 square kilometres, the North Pennine Orefield is the secondlargest area of lead and zinc mineralisation in the British Isles, only the geologically similar orefield in the Irish Midlands is larger.

Get Price -

Chanderiya LeadZinc Smelter [Largest LeadZinc Smelting]

Chanderiya LeadZinc Smelter overview. Chanderiya LeadZinc Smelter (CLZS) is one of the largest zinclead smelting complexes in the world. Its current metal production capacity is 643,000 MT per annum including 558,000 MT per annum of zinc and 85,000 MT per annum of lead.

Get Price -

Lead Recycling Plants

Lead Recycling Plants Providing you the best range of lead recycling plant, lead ingot casting machine, lead oxide plant, used lead acid battery recycling rotary furnaces, lead refining pot and metal melting rotary furnaces with effective timely delivery.

Get Price -

Metal Melting Furnaces Equipment | Charles A Hones

Metal melting furnaces manufactured by Charles A. Hones, Inc. are available in six standard sizes from 160 lbs. lead capacity up to 2,700 lbs. lead capacity. All melter's are rated for use up to 1,000OF. Furnaces can be used to melt lead, tin, solder, babbitt, bismuth, pewter, and related white or soft metals and their alloys. Furnaces are insulated with up to two inches of 1,200OF block ...

Get Price -

Lead recycling

Bergsöe completes the cycle. Boliden's lead smelter in Bergsöe is one of Europe's biggest recyclers of used leadacid batteries and as such plays an important part in the metal's life cycle. At Boliden Bergsöe the lead from 4 million wornout leadacid car batteries is recycled every year. At least 70 per cent of the lead produced here ...

Get Price -

Metals, Metal Products, and Machinery

Mills, foundries, casting, galvanizing, and metal products COMMON POLLUTANTS: Copper, lead, aluminum, TSS, COD and heavy metals In 1990, permitting regulations were developed by the Environmental Protection Agency (EPA) under the National .

Get Price -

Babbitt

· Babbitt of unknown composition. Magnolia Metal Corporation¶ Magnolia Metal Corporation began business in 1886 with a technical innovation in the then new bearing industry: the invention of leadbased babbitt metal. Less expensive than tinbased babbitt, "Magnolia AntiFriction" was soon being shipped around the world.

Get Price -

Products | Senju Metal Industry Co., Ltd.

Leadfree solder. Solder alloys. Alloys and their various forms. Flux cored solder. Solder paste. Solder preform. Solder balls.

Get Price -

CNC Machined Lead Parts | MarsMetal Specialty Casting Division

Mars Metal's specialized services include in house Precision 3D and CNC Machining of lead parts and lead plates utilizing state of the art equipment and the latest CADCAM software. We produce custom lead precision machined parts for the Medical, Communiions and Aerospace industries – including guidance systems, RDT security, satellite systems and all aspects of Government defense.

Get Price -

Adverse effects of 9 elements in iron ore on its smelting ...

· 9 elements in iron ore badly effected on its smelting. The minerals badly effected on the iron ore smelting are usually sulfur, phosphorus, potassium, sodium, lead, arsenic, zinc, titanium and copper. Generally, they have the following bad effects on smelting: Elements that bad for iron ore smelting. 1 Sulfur (S): it is the most harmful element ...

Get Price -

Cadmium in Forest Ecosystems around Lead Smelters in Missouri

cadmium and other heavy metals from the primary lead smelter at Belledune Harbor in New Brunswick, and discussed the metallurgy of cad mium within the conventional Imperial lead smelting process. For the past ten years, a team of investigators (6) has studied the dissemination of heavy metals from the mines, mills and smelters of Missouri's new lead * Life Sciences, University of Missouri ...

Get Price -

Northport Smelting and Refining Company

The eighteen folders of coded telegrams from Pennsylvania Smelter to Ramstedt, Nov. 1917Apr. 1921, include message forms and translation sheets giving code words and translations describing operation of the Pennsylvania plant (numbers of units in operation); amounts of bullion and lead received, produced, sold, and shipped; lead and silver price quotations; and amounts of metal on hand ...

Get Price -

Lead and Lead Alloys – The Lead Battery Recycling

Unit 700: Lead smelting The adopted technology is the smelting of leadbased materials in fixedaxis or in tilting rotary furnaces, equipped either with airfuel burner or with oxygenfuel burner. The unit includes the charging system through a dedied machine or through an automated materials metering and feeding group as well as a furnacededied baghouse filter .

Get Price -

Milling Machine: Parts, Types, Operations, Milling Cutter ...

· Milling is the machining process in which the removal of metal takes place due to the cutting action of a rotating milling a milling machine, the cutter is rotating due to workpiece is fed against machine can hold more than one tool at a time. The cutter rotates at high speed, and because of the many cutting edges, it removes metal at a very fast rate.

Get Price -

Primary Metal Manufacturing, New Brunswick Companies

Falconbridge Inc. Brunswick Smelter. 692 Main St., Belledune, NB. The Noranda Inc. Brunswick Smelter is a fully integrated primary lead smelter and refinery loed on an Atlantic yearround port near the village of Belledune in New Brunswick Canada. Recyclable feeds containing lead as well a .

Get Price -

Processing Ore

The smelting process is essentially very simple. Pellets of Galena are heated until they reach melting point. Because lead has a low melting point any impurities are not melted and are left as waste. The molten lead can be allowed to drain from the fire hearth into a collecting pot and then poured into moulds to form blocks of pure lead metal.

Get Price -

Mayco Industries | LeadBased Products

Mayco Industries is the largest, most diversified manufacturer of leadbased products in the United States. Mayco is the only source for your lead production needs, performing processes such as casting, rolling, machining, extruding, and coating. Mayco offers engineering support and design consultation on everything from small radiation ...

Get Price -

SAFETY WITH LEAD AT WORK

Lead is a toxic heavy metal and it is found in many different products including rolled lead sheeting, paints, glass, solder, plastic and rubber compounds, therefore, workers can be exposed to lead in a variety of work activities. Further detailed information is included in Appendix 2 relating to the use and risk of lead exposure in industry.

Get Price -

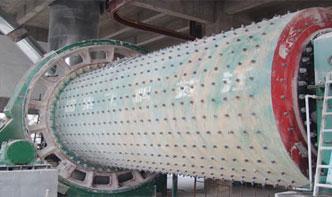

lead mill machine lead metal smelter

Lead Mill Machine Lead Metal Smelter process crusherCasting slag crusherOre CrusherGrinding list of manufacturer of casting parts for ball mill in Contact Supplier Appliion of Ball Mill in Slag Breaking Essay Ashedison At present the slag powder grinded by ball mill and classified by separator is widely used in the production .COZ 1900W Gold Electric Smelting Furnace with Mesh Guard, 2100F ...

Get Price