-

haematite processing plant in philippines

cost of factory that product recycling of iron 2012 in philippines; price for sand maker in philippines; tree milling machine repair manual in philippines; early stone crusher in philippines; flotation process flow chart in philippines; used crusher machinery for sale in china in philippines; mining equipment in south africa price in philippines

Get Price -

CHEMISTRY: The extraction of Iron and its impact on the ...

· Haematite, coke and limestone are fed into the furnace through the top. The following process takes place inside the blast furnace: Coke is added to haematite as it acts as a reducing agent for iron(III) oxide. Carbon, which comes into contact with haematite, reduces some of the iron(III) oxide. Reduction of iron(III) oxide:

Get Price -

the process in which iron is separated from its ore haematite

haematite ore beneficiation process visece mrezeeuhaematite ore beneficiation process africar hirecoza. Hematite beneficiation Iron Ore Beneficiation Hematite is an iron ore the chemical composition of Fe2O3 belonging to the iron oxide minerals Hematite beneficiation process is often used Hematite Processing by Flotation 911 Metallurgist Mar 19 Direct shipping of high grade iron ore because of ...

Get Price -

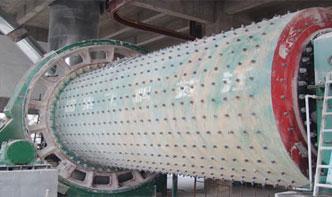

Haematite Processing Plant

Hematite Iron Ore Processing Plantportable Impact. The hematite iron ore processing plant vegetation is often carefully positioned along with the loion on the market to allow for a large amount of recyclable areas The goal is to keep shipping costs low The production process of the hematite iron ore processing plant can be separated by first producing a clinker at a temperature of.

Get Price -

processing of haematite

Processing of Banded Hematite Quartzite Ore for · The phase transformation of hematite to ferrite takes place sequentially, and intermediate reduced phases are formed as indied in Eqs ( 1) through ( 4) The stoichiometric amount of carbon required for complete reduction of hematite to metallic iron is calculated as ~505% according to Eq ( 5 )

Get Price -

haematite processing plant

Nowadays hematite iron ore processing has been a large demand of iron ore plant owner many hematite iron ore processing plants would consult peers on the website about which manufacturer is the best choice for extraction of iron from hematite Xinhai is your best choice Xinhai majors in manufacturing hematite iron ore processing equipment such as crusher grinding mill flotation cell...

Get Price -

processing of haematite

process of haematite mining . process of haematite mining ; process of haematite mining. Limonite Iron Ore. Limonite Iron Ore, Wholesale Various High Quality Limonite Iron Ore separator for concentrating Iron Ore/copper processing plant/copper mining equipment.

Get Price -

(PDF) Reduction of Haematite Using Hydrogen Thermal Plasma ...

The development of hydrogen plasma smelting reduction as a CO2 emissionfree steelmaking process is a promising approach. This study presents a concept of the reduction of haematite using hydrogen thermal plasma. A laboratory scale and pilot scale

Get Price -

haematite ore processing

· Processing Hematite Ore for Titanium Extraction Laboratory . 4 Apr 2017 . Please suggest the best route for processing and extracting iron content Fe 54% TiO2 12%, V %.Can iron be separated before feeding to the. Chat Online Iron Ore Magnetic Separation. 20 Apr 2017 .

Get Price -

A mineral haematite `(Fe_(2)O_(3))` contains unwanted ...

A mineral haematite `(Fe_(2)O_(3))` contains unwanted material called gangue in addition to `Fe_(2)O_(3)`. If 5 kg of the ore contains kg of iron

Get Price -

Study of the Magnetic Properties of Haematite Based on ...

The detection of the magnetic properties of haematite plays an important role in the adjustment of the beneficiation process of haematite and the improvement of metal recovery. The existing methods for measuring the magnetic properties of iron ore either have large errors or take a long time. Therefore, it is very necessary to find a method that can quickly and accurately detect the magnetic ...

Get Price -

Environmental impact of iron ore mining

Introduction Iron ore. Iron ore is rock containing enough iron content, and in sufficient volume and accessibility to mining and transportation to be able to be economically mined. Iron in ore iron is most commonly found in the form of magnetite (Fe 3 O 4), hematite (Fe 2 O 3), goethite (FeO(OH)), limonite (FeO(OH)·n(H 2 O)) or siderite (FeCO 3).Roughly 98% of iron ore on the global market is ...

Get Price -

Quantitative thermogravimetric analysis of haematite ...

· Assessment of the process relied on the quantitative analysis of haematite, goethite and kaolmite in the iron ore tailing and selective flocculation concentrates. Preliminary investigations showed that thermogravimetry (TG) might be suitable for the quantitative analysis of goethite and kaolinite because both minerals lose mass over a defined temperature range.

Get Price -

processing of haematite

Hematite also spelled haematite heavy and relatively hard oxide mineral ferric oxide (Fe 2 O 3) that constitutes the most important iron ore because of its high iron content (70 percent) and its abundance. Its name is derived from the Greek word for "blood " in allusion to its red colour. Many of the various forms of hematite have separate names.

Get Price -

processing of haematite

Hematite Iron ore beneficiation process flow. Hematite Iron ore beneficiation process flow The haematite s another name is red iron ore and its chemical structural formula is Fe203 it s a weak magnetic iron ore...

Get Price -

The Six Main Steps of Iron Ore Processing | Multotec Canada

· When the iron ore is extracted from the mine, it must undergo several processing stages. Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher's CSS before the crushing stage. A static screen is .

Get Price -

Processing Of Haematite

Types of Iron Ore: Hematite vs. Magnetite INN. Iron ore is most often found in the forms of hematite and magnetite. Learn what makes those types of iron ore different and make an informed investment. processing magnetite ores result in a. Extraction of Iron from Haematite Reference Notes. 1.

Get Price -

haematite processing plant

Beneficiation Of Haematite Iron Ore Beneficiation process of iron ore hematite dry separation hematite iron ore roasting for beneficiation hematite beneficiation process for iron ore processing 183 apr 3, 2014 iron ore is a mineral which is used after extraction and processing for the the main ores of iron usually contain fe2o3 70 iron, hematite or fe3o4 a typical flow sheet for iron ore

Get Price -

EXTRACTION OF IRON IN A BLAST FURNACE reduction haematite O

EXTRACTION OF IRON IN A BLAST FURNACE Iron is also below carbon in the reactivity series, so therefore carbon can be used to reduce it (note: reduction can also mean to remove the oxygen from a compound). This is done in a blast furnace. The most common ore of iron is called haematite (iron(iii) oxide). Its formula is Fe 2 O 3.

Get Price -

haematite, magnetite, magnisite, limonite iron ores

Chapter 8, Iron Ores. 23 May 2012 ... ican steel industry, approximately one net ton of iron ore (including agglomerates) is consumed, ... Magnetite has a chemical composition of Fe3O4, corresponding to % iron and % oxy ...

Get Price