-

Cement Grinding Ball Mill Price,Raymond Mill Operation Pdf

coal mills pfeiffer; asphalt grinding mill; mill wet grinding of mica; used miller welding machines for sale in uk; free surface diaphragm ball mill; diagram on h milling machine; grinding process in cement plant; austria gold rolling mill; price for maize grinding mill; ball mill for rock phosphate canada

Get Price -

Proposed Modifiion of Holcim Davao Cement Plant and ...

the cement mill for the cement grinding process. The grinding process comprises 90% of clinker, 5% gypsum, and 5% mineral filler. The cement mill has a designed capacity of 210 tph. Figure 1 presents the material balance of Holcim Davao plant. Raw Materials

Get Price -

The difference between ball mill and vertical mill in ...

The difference between ball mill and vertical mill in cement grinding Over the last three decades the vertical roller mill has become the preferred ball mill for grinding of raw materials. The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill system.

Get Price -

UltraTech Cement Limited: Unit

Aligarh Cement Works RWCW Integrated Units Grinding Units Bulk Terminals Mangalore Bulk Terminal Shankarapally Bulk Terminal Navi Mumbai Cement Unit Dankuni Cement Works ... Conversion of Coal Mill Cement Mill ESP to Bag house to reduce emissions to < 20 Mg/Nm3 Ever highest kiln refractory life achieved in Line2 : Months

Get Price -

3 A cement grinding mill A with a capacity of 50 tons per ...

A cement grinding mill "A" with a capacity of 50 tons per hours utilizes forged steel grinding balls costing P12, 000 per ton, which have a wear rate of 100 grams per ton cement milled. Another cement mill "B" if the same capacity uses high chrome steel grinding bans costing P30, 000 per ton with wear rate of 10 grams per ton cement milled.

Get Price -

C. Woywadt, Gebr. Pfeiffer SE, Kaiserslautern, Germany

The cement grinding mills MVR 6000 C6 are designed to produce different types of cement and blastfurnace slag meal. Therefore, all dry and wet components such as clinker, gypsum and wet fly ash are fed by belt conveyors through a rotaClinker Gypsum Wet .

Get Price -

[PDF] Cement grinding optimisation | Semantic Scholar

Abstract The current world consumption of cement is about billion tonnes per annum and it is increasing at about 1% per annum. The electrical energy consumed in cement production is approximately 110 kWh/tonne, and around 40% of this energy is consumed for clinker grinding. There is potential to optimise conventional cement clinker grinding circuits and in the last decade significant ...

Get Price -

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side. System Description Mill Rated capacity 150 t/h OPC at .

Get Price -

Cement Formulae

12. Ball MillBall Weight Surface Area 97 13. Ball Mill Charge Volume 98 14. Useful Data for Grinding Mill Study 99 15. Ball Mill Charging 99 16. BIS Specifiion of Additives 102 17. BIS Specifiions for various 103 Cements 18. Thermo Physical Properties of Different Insulating Materials 107 19. Pollution Standards for Stack, Ambient ...

Get Price -

WalkBehind Milling Machines and Floor Grinders

WalkBehind Milling Machines and Floor Grinders Using walkbehind milling machines and floor grinders on concrete or other silicacontaining materials can generate respirable crystalline silica dust. When inhaled, the small particles of silica can irreversibly damage the lungs. This fact sheet describes

Get Price -

Predictive Controller Design for a Cement Ball Mill ...

The annual cement consumption in the world is around billion tonnes and is increasing by 1% every year [1]. Cement industries consume 5% of the total industrial energy utilised in the world [2]. A total of 40% of the total energy consumption of a cement plant is used in clinker grinding in a ball mill to produce the final cement product [3].

Get Price -

Teresa plant, the Philippines: cement grinding plant.

the mill, thus ensuring a comfortable mill stability margin. It also offers a competitive, simple, and proven solution to cement producers willing to capture new and potentially changing markets in the fastest way. Conclusion Whether considering raw meal grinding, cement grinding, or slag grinding.

Get Price -

Electric Grinding Mill Components Pdf

201814 A ball mill investigated in this study is used for grinding of limestone in a cement plant. It consists of a large cylindrical shell which ends with inlet and outlet tubes that are supported in journal bearings. The drive of the ball mill consists of an induction electric

Get Price -

Ball Milling Method Pdf Manufacture and Ball Milling ...

30/07/2021 · Ball Milling Method Pdf manufacturer, factory, supplier from China. (Total 24 Products for Ball Milling Method Pdf) Dia. 20150mm Forged / Forging Grinding Steel Ball. Brand: ShengYe. Packaging: Steel Drums Flexible Container Bags. Supply Ability: 150,000 tons/year. Certifie: TUV ISO 9001 / ISO45001 / ISO14001.

Get Price -

No. 1/2004 New cement grinding plant for the Koromacno ...

further cement types with finenesses of 3500 to 5000 cm2/g. The existing closedcircuit grinding plant essentially comprises a ball mill with the dimensions x and a cyclone air separator type ZUB 42/6. No. 1/2004 New cement grinding plant for the Koromacno works,HOLCIM (Hrvatska),Croatia Loion of the new grinding plant

Get Price -

cement mill grinding theory pdf Filtro magnético

19/01/2020 · cement grinding mill pdf. cement mill grinding theory pdf italy Cement grinding Vertical roller mills versus ball mills. cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding.

Get Price -

Optimization of mill performance by using

a mill grindout (no ore feed) of 10 to 20 minutes is also performed before mill inspection or relining. The complete grindout is required to obtain the accurate ball load measurement or the percentage by volume of balls in the mill. This is usually performed soon after a crash stop.

Get Price -

cement cement grinding mill pdf

Cement grinding optimisation Request PDF. The energy efficiency of ball mills for use in finish grinding is relatively low consuming up to 3042 kWh/ton clinker depending on the fineness of the cement (Cembureau 1997Marchal 1997).get price

Get Price -

Concrete Milling

Concrete Floor Milling. Concrete Floor Milling is the bulk removal of concrete (between 5mm and 50mm deep) from a concrete floor. Concrete milling machines leave a coarse texture that is suitable for relaying tiles. The consumables that are used in concrete milling are Tungsten Carbide Cutting Teeth, which are inexpensive and widely available.

Get Price -

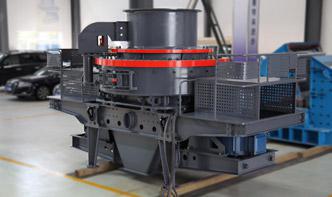

Industrial Raymond Vertical Mills Cement Grinding Mill

Grinding mill includes micro powder mill,vertical mill,coal mill and ball mill,Rtype Raymond mill is used for grinding the barite, limestone, kaolin, ceramics, and. Prices / Quote How Cement Vertical Grinding Mill Machine Works Pdf

Get Price -

Some tests on the grinding of cement clinker with a ...

this mill will last much longer in the cement industry in vie of the constant demand for lower maintanance and higher capacity. The Huntington Mill ill grind between 18 to 30 barrels of cement clinker per hour to a fineness of 60% through 100 mesh and finer. Th average capacity is about ~0 . .

Get Price