-

Cone Crushers

Cone crushers are a type of compression crusher used by aggregate, coal, concrete, crushing, fracking sand, and mining industries, which reduces material by squeezing or compressing it until it breaks. By continuously optimization and innovation, we focus on improving product structure, upgrading raw material and optimizing assembly process.

Get Price -

A Dynamic Model of Inertia Cone Crusher Using the Discrete ...

The cone crusher plays a vital role in mineral processing, which has been used widely in medium and fine crushing stages in mineral processing comminution operations [1]. As a variant of the cone crusher, the inertia cone crusher is an extra performance crushing equipment in .

Get Price -

Crushing Principle, Gear Wear and Solution of Cone Crusher ...

· principle of cone crusher. When the crusher works, the motor drives the eccentric sleeve to rotate through the horizontal shaft and a pair of bevel gears. The main shaft of the crusher rotates under the force of the eccentric sleeve, so that the surface of the crushing wall is sometimes close to and away from the surface of the ...

Get Price -

51/2" Cone Crusher Parts | Sinco

HighQuality 51/2″ Cone Crusher Parts. When it comes to 51/2″ Cone Crusher Parts, Sinco Machinery has been crushing the market for decades, which include Mantle, Bowl liner, Mainshaft bushing, Frame bushing, Socket Liner, Transmission shaft bushing, Upper thrust plate, Eccentric shaft, Pinion gear, Bever gear, Eccentric bushing, Transmission shaft assembly,Main .

Get Price -

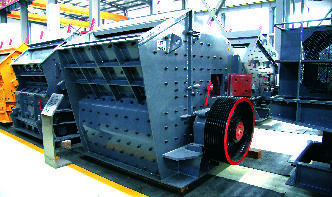

Stone Crushers, Crushing and Screening Equipment, Jaw ...

The company is equipped with a professional design team to help customers sample, test, measure and analyze materials, free of charge. After combining with the site conditions, production capacity, requirements of final discharge particle size and investment cost budget, the company conducts feasibility analysis and demonstration, designs process and scheme, provides customers with solutions ...

Get Price -

Analysis of Common Failures and Causes of Cone Crusher ...

The crusher often vibrates. 1) For spring cone breaking, when the spring tension of the crusher is not enough, the crusher will often vibrate. 2) When the feeding of the crusher is uneven or excessive, it will often cause the crusher to vibrate. 3) When there is too much fine ore in the feed of the crusher and it is wet, the ore discharge port ...

Get Price -

Crushers

Cone crushers . Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not needed.

Get Price -

Common Faults and Solutions of Cone Crusher | Quarrying ...

Cone crusher is the most common secondary and tertiary crushing equipment. ... the axial clearance of the transmission shaft is too large, or the gear is damaged. Solution. Correct the meshing gap or replace the gear. 13. Support ring bounce. The reason. Metal or other hard objects that cannot be crushed fall into the crushing cavity.

Get Price -

CH890i CH895i CONNECTED CONE CRUSHER

CONE CRUSHER CH890i and CH895i are technologically advanced, highcapacity cone crushers designed for crushing appliions in mines or large sized quarries. Each crusher has a hydraulically supported main shaft which is supported at both ends. The main shaft .

Get Price -

Gyracone J Series Cone Crushers

Shaft thrust bearings 16. Spiral bevel gear and pinion 17. Countershaft bearings 18. Cartridge type countershaft assembly 19. Pulley 20. Piston for hydraulic shaft adjustment ... Gyracone J Series Cone Crusher Construction Details 8. Troublefree lubriion A motorised gear .

Get Price -

cone crusher

Manufacturer of cone crusher Cone Crusher Headcentre With Main Shaft, Cone Crusher Bottom Sheel All Parts, Concave Mantle and Cone Crusher Jaw Crusher Accumulator offered by Roy Spare Tech Enterprise, Kolkata, West Bengal.

Get Price -

Cone crusher, Cone crushers, Cone crusher ...

Cone crusher consist of frame, transmission device( countershaft, countershaft bushing, gear and pinion), main shaft, eccentric shaft, cone,mantle, bowlshaped bearing, springs and hydraulic pressure station for adjusting discharge opening.

Get Price -

Raptor® Cone Crushers for Aggregates

We offer a full line of cone crushers that are designed for you. Our line of Raptor Cone Crushers is the most diverse product line on the market, including a broad range of sizes and features. For aggregate appliions, we recommend the R250 to the R450, though we also offer larger crushers that are typically used in mining.

Get Price -

® HP Series™ Cone Crushers Brochure

new generation cone crushers: Keeping you ahead There's no better choice than a cone crusher when it comes to . . . • high productivity, • low operating and wear costs, • long service life, and high product yield with desired shape and gradation. leads this market with its high performance HP Series cone crushers for the aggregate and mining markets.

Get Price -

® Cone Crusher Parts_Shenyang Powerups Machinery

Premium Parts for ® Cone Crusher Powerups has been specializing in manufacturing premium quality aftermarket wear and replacement parts since 1990s, providing more competitive parts and service than typical parts suppliers in the world.

Get Price -

Raptor® Cone Crusher best in class | FL

Raptor® 900. Our R900 is the smallest of the cone crushers that we designed specifically for mining. It can handle the larger loads, common in the mining industry. This model has many advantages for its size. Large and robust with a rigid fourarm mainframe and integral countershaft. m (70 in) head diameter.

Get Price