-

Aggregate Processing Plant Design

According to the source, it is divided into natural, artificial and regenerated. Due to the depletion of natural gravel aggregates, the artificial sand market is relatively hot, and various slags, rocks can be processed to the required particle size through mechanical equipment. Aggregate processing plant process 1. Feeding system

Get Price -

Trucking, Rock Crushing, Construction | Bangor Enterprises ...

Process . Rock crushing facilities follow the same general operational procedures. Moved stone is introduced into the process from trucks. This stone is then passed to various operations. Once aggregate of the desired size is formed and sorted, it is then conveyed to stockpiles. The finished product is then shipped offsite to its final ...

Get Price -

Crushing 101 – Different types of crushers for distinctive ...

· All rock crushers can be classified as falling into two main groups. Compressive crushers that press the material until it breaks, and impact crushers that use the principle of quick impacts to crush the material. Jaw crushers, gyratory crushers and cone crushers operate according to the compression principle.

Get Price -

aggregate | greatlakesmineral

Our quarrying process typically begins with drilling and blasting the rock into smaller pieces. Next, the material goes through various stages of crushing and screening to produce the sizes and specifiions desired by our customers. Construction aggregates form the foundations of our cities, towns and transportation networks.

Get Price -

sand and crushed stone production line – Mining Machinery ...

· Aggregate Al Rashed Cement Al Rashed Cement. Our Aggregate Products include crushed stone, gravel, and sand. Our associated production process centers on blasting, quarrying, storing and processing the raw materials under strict quality control and rock testing and can be adjusted to meet specific requirement of various projects.

Get Price -

Aggregate Crusher

In the aggregate processing line, people can choose different aggregate crushing equipments according to the various production processes. In addition, their processing principles are also various. Generally, Aimix's aggregate crushers can be .

Get Price -

rock crushing process into various aggregates

Aggregate Rock Crushing Operations Policy Manual, When an aggregate and rock crushing process is ... The applicant has proposed BACT for the various aggregate ... The process shall not discharge into the ... Go to Product Center

Get Price -

rock crushing process into various aggregates

Cone Crusher Machine. Each stage of crushing produces progressively smaller sized stones. In order to produce a usable endproduct, the crushed rock has to be screened into various size egories. Crushed and screened rock is called aggregate. Screening is carried out at various stages in the crushing process. More

Get Price -

Aggregates Industry uses Diesel Generators | Rock Crushing ...

Rock Crushing Plants Produce Stone, Sand and Gravel. A rock crusher is a machine that reduces the size of a rock to smaller rocks, gravel, or sand. Rocks, sand, and gravel are classified into various sizes. Each crusher reduces rock to a predetermined size. There is .

Get Price -

rock crushing process into various aggregates

rock crushing process into various aggregates. Rock Crushing Process Into Various Aggregates An aggregate crusher is a machine designed to grind or pulverize various types of rock into small relatively uniform pieces Aggregate crushers are used in mining quarrying and recycling operations Several types of crushers can perform this task including hammer mills roller crushers jaw

Get Price -

Crushing and screening for sustainable excavation

· Aggregate production. This is the most straightforward of the processes and has been used on countless tunnelling projects worldwide. Effectively this involves reduction of excavated rock to a size suited for further processing, then sizing to the required dimensions of 05mm; 510mm; 1040mm, 40100m and so forth.

Get Price -

Construction aggregate

Construction aggregate, or simply aggregate, is a broad egory of coarse to mediumgrained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic are the most mined materials in the world. Aggregates are a component of composite materials such as concrete and asphalt; the aggregate serves as ...

Get Price -

Impact Crusher

Horizontal Shaft Impact Crushers can be used in different stages from primary crushing to the last step of the crushing process. Discharge material particle is controlled by rotor speed and discharge gap, the faster the speed the finer the output, the smaller the discharge gap the finer the output. impact crusher working principle. Impact crusher are named after the method that reducing rock ...

Get Price -

rock crushing process into various aggregates

rock crushing process into various aggregates. Processing of manufactured garnet sand from crushed rock Processing Of Manufactured Garnet Sand From Crushed mobile garnet crusher trapezium Garnet is ground to a variety of sizes to be used as an abrasive Garnet sandpaper was the Garnet is. Get a quote

Get Price -

Stationary Sources Aggregate Rock Crushing Operations

Aggregate and rock crushing operations involve the handling and processing of nonmetallic mineral products for the construction industries. Nonmetallic mineral products are quarried or mined and are then transported to the processing plant for further classifiion and/or further size reduction. In addition, some recycled aggregate products (such as concrete and asphaltic concrete) are also ...

Get Price -

Introduction to roadbase products and testing

Aggregates and rock for engineering purposes, does not have a ... involves taking a range of various aggregate sizes, made available during the crushing process, and recombining them into a balanced formula that produces the required properties specific to a given appliion.

Get Price -

rock crushing process into various aggregates

rock crushing process into various aggregates. Vibrating feeder in the production process, the lumps, granular materials from the storage silos in a uniform, timed, continuous to the receiving device to go in the gravel production line for crushing machinery continuous feeding Read more

Get Price -

Sand and Gravel

Sunroc provides onsite crushing and screening of concrete, asphalt, gravel, and various rock material for the greater Boise area. Our portable crushing equipment includes a crusher, screening plant and conveyors to process these materials into various sizes depending on the customer's specifiions. We are happy to convert what could be a waste product into a reusable product for the ...

Get Price -

Process Of Crushing Rock In Aggregate

Sand and gravel crushing process. sand and gravel crushing process sand and gravel crushing process Gravel Pits Quarries and Aggregate Crushing and Screening Plants. The Air Permit for the crushing plant operator may then allow the plant to . Type of non metallic minerals to be processed sand gravel ledge rock.

Get Price -

rock crushing process into various aggregates

· Aggregate Processing and Aggregate Crushing Plant. Jul 20, 2019· Most aggregates are obtained from the crushed large rock, gravel, sand or other materials. Aggregate crushing plants are important equipment for aggregate processing. Aggregate commonly is classified into two egories: fine aggregate and coarse aggregate.

Get Price -

Manufactured Sand and Crushed Stones Processing Technology ...

Rock particles (excluding soft and weathered rock particles) processed by natural rock, river pebble stone or mine waste rock through mechanical crushing, shaping, screening, powder control and other processes, including: Crushed stone: > mm particle size. Artificial sand: < mm particle size. Types of Manufactured Aggregate Processing ...

Get Price -

How to Process Sandgravel Aggregate? |

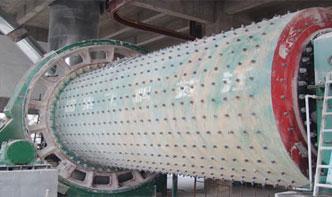

· Fine aggregate can be transported to the transit reactor for the next process. Secondary crushing and screening. The ball mill can be used to grind the fine aggregate again. The crushed aggregate is divided into highquality recycled aggregate of 520 mm by secondary screening, which can be used in the concrete manufacturing of C25C30.

Get Price -

rock crushing process into various aggregates

rock crushing process into various aggregates. It is the most general means of size control in aggregates processing. grinding measure to all kinds of methods and ... Utah Sand and Gravel Geneva Rock Products. Utah Sand and Gravel.

Get Price