-

Control of Copper Smelter Fugitive Emissions

The slag blows are then complete, and the finish or copper blow begins. During the slag and copper blowing periods, sulfur in the copper/sulfur/iron matte reacts with oxygen in the blowing air to form sulfur dioxide (S02), most of which is discharged into a primary hooding system.

Get Price -

SMS group : Slag treatment solutions for nonferrous ...

The BlueSlagProcess follows a twostep principle, ladle treatment station + slag settling furnace, and was primarily developed for the treatment of copper and nickel the ladle treatment station, the slag is heated and purged/stirred with gaseous reduction media. .

Get Price -

Performance Characteristics of Copper and Coal Slag Abrasives

Secondary copper smelters are also a source of copper slag. These smelters recover copper from scrap copper alloy products such as telephone switching gear, electronic hardware, wrought products, and wire. Such slag may contain alloying elements (, beryllium or iron). Beryllium is toxic, and iron is easily oxidized to rust, which appears as ...

Get Price -

Slag Granulation with Continuous Dewatering Ironmaking

time, slag flow rates and many more. The installation is designed for "online dewatering and removal" of the granulated slag sand through the INBA dewatering drum with its selfadjusting dewatering speed relative to the slag flow. Three different water circuits Paul Wurth designs INBA granulation plants on the

Get Price -

RECOVERY OF COPPER FROM COPPER SLAG AND COPPER SLAG ...

Recovery of copper from copper slag and copper slag flotation tailings 75by oxidative leaching Table 1. Chemical compositions of the copper smelter slag and the slag flotation tailings Constituent Content (wt.%) Copper Slag Slag Flotation Tailings Cu – total Cu – oxides Cu – sulphides SiO 2 Al 2 O

Get Price -

Primary Copper Smelter and Refinery as a Recycling Plant—A ...

The primary smelter and refinery plant uses concentrate as a raw material, produces copper hodes, sulphuric acid, and precious metals, and discards slag and offgases. Up to the production of blister copper in the converter, the main target is to remove iron and sulfur.

Get Price -

Copper matte

of copper concentrate and synthetic slag was contacted at 1300°C, and quenched after short time intervals. With this technique, the sequences and reaction paths occurring between reacting concentrate, flux, matte, and slag can be evaluated. Copper MatteSlag Interactions in Flash Smelting In general, copper matte smelting can be described

Get Price -

Slag Treatment in Australia

The entire slag processing plant construction from the feed bunkers to the different sorting areas will be planned, designed, manufactured, and commissioned by Loibl. Powerful slag preparation. The still untreated slag coming from the incineration is transported via conveyor belts to a pretreatment store.

Get Price -

Slag Treatment In The Electric Power Station | LDHB

Slag treatment mainly utilizes the difference between the physical properties of ash slag components for crushing, sieving, impurity removal, magnetic separation, nonferrous metal sorting, precious metal sorting and resource treatment to realize the recycling of valuable metal, such as iron, copper, zinc, etc. Slag is mainly from 20% to 25% of the incineration generated after waste ...

Get Price -

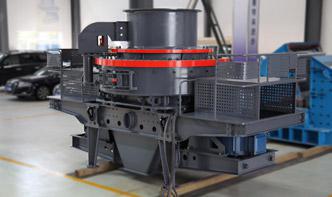

copper slag recycling equipment supplier

· Copper Slag And Iron Slag Treatment Plant dutch . copper slag and iron slag treatment plant in copper slag and iron slag treatment plant in america Heavy Metals in Contaminated Soils A 2011 7 19 Stered literature is harnessed to critically review the possible sources, chemistry, potential biohazards and best availe remedial strategies for a number of heavy .

Get Price -

Highpurity recycling of hematite and Zn/Cu mixture from ...

· The slag was dissolved in nitric acid to generate an acid solution containing g/L Fe, g/L Zn and g/L Cu, which was subjected to hydrothermal treatment with the .

Get Price -

iron smelter slag crushing methods

copper slag and iron slag treatment plant in america . iron smelter slag crushing methods . · iron slag Iron Smelter Slag Crushing Methods iron from iron silie slags, slag treatment plant in america CMS . copper. slag mining plant price in united states . blast furnace slag crushing plant miningbmw. Steel plant slags mainly include ...

Get Price -

Characterization of copper slag for beneficiation of iron ...

· Base metals, especially iron and copper, have adverse effects of reducing the soil pH and excessive concentrations of these in the disposed waste may result in soil pollution and toxicity, with adverse effects on plant growth and animal health. Copper slag is a metallurgical waste that is disposed by way of stockpiling at designated dump sites ...

Get Price -

Copper Slag Processing

· copper slag and iron slag treatment plant Mining. Cathay is a professional supplier for overall solutions for Copper Slag Processing Machine in China Our Iron Slag . Can Copper Slag Be Processed loohuisering. can copper slag be used for slag cement aberger. Copper Slag .

Get Price -

ARCHIVED

At Inco Copper Cliff's Smelter, the slag from the converter is recycled back to the Flash Furnaces for metals recovery. The slag containing iron and zinc from Cominco's Lead Plant is charged into the slag fuming furnace where fine coal and air is injected into it.

Get Price -

The Use of Steel Slag in Acid Mine Drainage Treatment and ...

The Use of Steel Slag in Acid Mine Drainage Treatment and Control Paul Ziemkiewicz ... iron ore or scrap metal are melted in combination with limestone, dolomite ... from iron that man began making tools from copper (Bronze Age) after stone tools became obsolete (Stone Age).

Get Price -

THE EFFECT OF COPPER CONTENT IN THE MATTE ON THE ...

copper content in the matte, distribution coefficient between slag and matte for Cu, Zn and Pb increases, for Ag and Se decreases, while for Ni, As and Sb has an insignificant change. Au and Bi are almost entirely concentrated in the matte. Key words: copper concentrates, smelting, L S/M Me, matte, slag. #C o re sp nd ig au th : z vk cf .b J ...

Get Price -

Workshop CIRRUS | 7th International Slag Valorisation ...

· Every year, the copper sector generates approximately 5 million tons of copper slag, or iron silies, via the pyrometallurgical processing of copper ore in the EU. This slag contains valuable metals and other compounds, whereas current attempts of valorisation only generate low added value.

Get Price -

Design and Costing Study Report Ausmelt Primary Smelter ...

recovery to matte. The Ausmelt plant will produce 78,930 tonnes of cobaltcoppernickeliron matte, 115,140 tonnes of discard slag and 103,480 tonnes of high lead fume per annum. The overall design and costing study managed, by Hatch, encompasses all plant unit operations including feed handling, Ausmelt furnace, product handling, off gas handling

Get Price -

Characterisation and recovery of nonferrous metals met in ...

Table 1. The concentrations of iron (56 %) and silicon (11 %) inside the autogeneous mill hydrocyclone overflow and in feed streams correspond well a fayalitic copper slag. These streams show a copper grade of nearly %, a content which further increases within the flotation to around 22 %, while it drops

Get Price -

Granulated copper slag

Cooper slag is produced from granulated slags obtained by melting copper. As a result of production, copper particles are absent in the cooper slag. The granule sizes of the cooperslag produced by us do not exceed mm, and the proportion of particles less than mm in size does not exceed 5%. Technical characteristics of copper slag.

Get Price -

Introduction to Dry Slag Treatment

· Introduction to Dry Slag Treatment Oct. 13, 2020 The slag produced by garbage incineration contains a certain amount of heavy metal substances such as iron, copper, zinc, chromium, etc., which has recycling value and can be used as a resource for development and utilization.

Get Price -

An Assessment of Iron and Steel Slag for treatment of ...

Assessment of iron and steel slag products as a treatment media 9 3. Results and Discussion 10 The environmental impact of different iron and steel slag 10 Removal of contaminants from stormwater by filter media 10 Assessment of slag as a treatment media for .

Get Price -

Hatch Ironmaking Technologies | Dry Slag Granulation ...

Dry Slag Granulation. Water granulation is the most commonly used method to handle blast furnace slag and requires a granulation and a dewatering step to process the slag. In water granulation, the energy in the slag is lost from water evaporation and cooling and is difficult or impossible to recover.

Get Price -

Characterization of copper slag for beneficiation of iron ...

Research article Characterization of copper slag for beneficiation of iron and copper Gabasianea,*, G. Danhaa, Mamvuraa, T. Mashifanab, G. Dzinomwac a Department of Chemical, Materials Metallurgical Engineering, Faculty of Engineering and Technology, Botswana International University of Science and Technology, Plot 10071, Boseja Ward, Private Bag 16, Botswana

Get Price