-

(PDF) Performance Evaluation of Vertical Roller Mill in ...

Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the ...

Get Price -

Home []

ball mill parts We provide a variety of wearresistant spare parts for ball mills, including liners, diaphragm, wearresistant grinding balls, etc.; Our company keep a good cooperative relationship with .

Get Price -

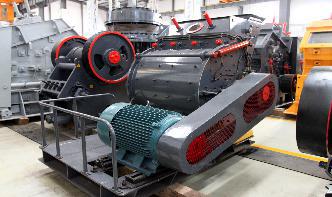

Hammermills versus roller mills | ...

Roller mills, particularly single pass installations, require more care and attention than hammermills in order to achieve a consistent and accurate grind. Ensuring the feed is spread thinly across the face of the roller mills can present some problems as mechanical feed gates can easily become obstructed, impairing the smooth and regular flow ...

Get Price -

Aerospace and Transport | Chemical engineering

The vector stencils library "Industrial equipment" contains 81 symbols of pumps, compressors, fans, turbines, and power generators. Use these shapes to design pumping systems, air and fluid .

Get Price -

Fluid Handling | Sepor, Inc

Transport water and other nonaggressive chemicals. Delivers process water to heat exchangers, air scrubbers, spray systems and 030A other process/pilot plant equipment. Available with close couple .

Get Price -

Grinding | PSP Engineering

Pneumatic ball mills. With pneumatic ball mills, material is discharged by air flow. The material is further conveyed to a dynamic separator, which together with the mill forms a pneumatic ball mill grinding plant. In view of the fact that process air flow is high, these grinding.

Get Price -

Design, Construction, and Operation of a HighEnergy Mill ...

Feb 07, 2019 · A highenergy mill was designed and built with the purpose of processing magnesium (Mg) powders. The main characteristics of the mill are grinding capacity of 1 kg and demolition .

Get Price -

For Most Machinery

m 144 eurowrap 380 flow pack with biscuit feeder . m 143 eurowrap 280 flow pack . j 107 bch copper coating pan . ... j 068 300 kg stainless steel chocolate ball mill refiner . j 067 100 kg .

Get Price -

Highperforming gear unit for your ball mill

Ensure reliable ball mill operation with our efficient gear unit. Power efficiency exceeds %. The twostage planetary configuration of our CPU Gear Unit delivers almost power efficiency, translating .

Get Price -

feasibility of limestone quarry in nigeria,how to set a ...

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Ball mills .

Get Price -

BMX 400

> BMX 400 – ball mill system for laboratory appliions Dry grinding systems, which include ball mills, are usually very complex and complied. They require ball mills working in the closed circuit with an air classifier and a complete circuit has to operate with the pneu¬matic transport .

Get Price -

Horizontal slurry pumps

VASA HD Series horizontal slurry pumps are an excellent choise for appliions where the smallest MD Series or X Series pumps are too large. Furthermore, VASA HD pumps are well suited for when a higher maximum pump operating pressure is needed. Flow .

Get Price -

USB2

An agitator ball mill for finely grinding or dispersing material has a cylindrical or conical grinding chamber for accommodating grinding bodies and for accommodating the material which is to be ground or .

Get Price -

(PDF) Grinding in Ball Mills: Modeling and Process Control

Jun 01, 2012 · Grinding in ball mills is an important technological process applied to reduce the. size of particles which may have different nature and a wide diversity of physical, mechanical and chemical ...

Get Price -

Slurry flow in mills: gratepulp lifter discharge systems ...

Pulp lifters, also known, as pan lifters are an integral part of the majority of autogenous (AG), semiautogenous (SAG) and grate discharge ball mills. The performance of the pulp lifters in conjunction with grate design determines the ultimate flow capacity of these mills. Although the function of the pulp lifters is simply to transport .

Get Price -

Turkish Flour Mills Suppliers, Manufacturers, Wholesalers ...

Millma roller mills have huge power and capacity and they are produced using excellent engineering and labour. Models of single and double decks are available. Feeding screen is controlled as servo in .

Get Price