-

Tungsten Tailings Utilization

Sep 29, 2019 · JXSC has 35 years of experience in the mining industry, we produce mining equipment, design processing flowchart for customers. Mining equipment: jaw crusher, cone crusher, impact crusher, hammer crusher, roller crusher, vibrating feeder, vibrating screen, gravity separator, flotation machine, magnetic separator, conveyor belt.

Get Price -

high quality copper crusher for copper ore processing plant

Mar 01, 2020 · Copper Ore Processing Plant is mainly used for copper ore beneficiation with Main Equipment: jaw crusher ball mill spiral classifier flotation machine dryer etc. Excellent copper concentrate separation effect can be obtained by flotation in are always here to provide you with high quality products and better services.

Get Price -

copper processing plant, copper flotation plant, copper ...

Flotation is the common copper processing technology, which can be used for sulfide ore and oxide ore. The copper flotation plant usually includes following steps: crushing and screening, stage grinding and flotation, thickening and dewatering, and copper concentrates recovery.

Get Price -

Mining/Ore Milling

We use a variety of machinery combinations to liberate the gold and concentrate it for recovery. The allinclusive TurnKey Ore Processor will take a loaderbucket of ore and produce concentrated gold and sulfides with no handson activity by the operator. For a less costly production system, using handfed machinery, we offer a jaw crusher, hammer mill, and shaker table each one a standalone ...

Get Price -

rock gold mining equipment the gold mining process

Jaw crusher, centrifugal concentrator and shaker table are commonly used as rock gold mining equipment. The above rock gold mining process could have effectively recover >75% of gold. Hengcheng offers turnkey solutions for rock gold processing plant. Our factory specialized in the fabriion of gold processing plant for more than 20 years.

Get Price -

copper and nickel flotation equipment stone crusher machine

Jul 12, 2021· Before the beneficiation of copper ores, crushing and grinding are required. The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher. Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to Copper ore crushing process.

Get Price -

China best european copper jaw crusher plant

China best european copper jaw crusher plant. Loading +86 150 2750 8176 [email protected] ... Up to now, with 2000 servied mine projects, 500 mineral processing EPC+M+O projects, 70 kinds of ores mining technologies and experience and 112 patents, Xinhai has established multiple overseas offices in Asia, South America and Africa and exported to ...

Get Price -

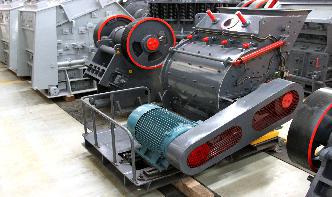

Jaw Crusher

Jaw crusher is a robust size reduction equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical and allied industries. Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with the capacity range of 11000tph.

Get Price -

jaw Portable Small Scale Free Gold Gravity Concentration ...

May 11, 2021 · Artisanal and Small Scale Hard Rock Gold Processing Plant The raw ore is first crushed by the jaw crusher, then it is fully crushed by the hammer mill to liberate free gold completely. gravity separation processing obtains the concentrate is further smelted and casted to get the bullion. ... Sets (MOQ) CN. Scale Mining Gold Copper Mining ...

Get Price -

Copper Ore Processing Equipment / Sulfur Copper Ore ...

STEP 1: By the jaw crusher preliminary crushing, the copper ore stone comes into the hammer crusher for second crushing. STEP 2:. After hammer crusher, copper ore stone will come into ball mill for fine copper mineral will come into next stepmixer for mixing, the bigger copper mineral needs to return to the ball mill again by the rotating of spiral classifier.

Get Price -

Copper Ore Processing Methods

· Copper Ore Processing Methods. The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining. In a few instances, however, leaching takes the place of concentrating, smelting, and refining. At present, although considerable leaching and directsmelting ores are produced, the bulk of the copper ore ...

Get Price -

Copper Production Line|Copper Ore Process Machine

According to the beneficiation process, the copper ore processing flow can be: crushing – grinding – classifying – flotation – copper concentrate and tailings process. 1. Crushing machine: Triple or fourfold crushing are adopt for the copper ore crushing in the medium and large mining plant. Adhering to the modern dressing concept of ...

Get Price -

Oxide Copper Ore Processing Plant Flotation Machine Price ...

STEP 1: By the jaw crusher preliminary crushing, the copper ore stone comes into the hammer crusher for second crushing. STEP 2:. After hammer crusher, copper ore stone will come into ball mill for fine copper mineral will come into next stepmixer for mixing, the bigger copper mineral needs to return to the ball mill again by the rotating of spiral classifier.

Get Price -

KAZ Minerals | Focused on copper

When sent for smelting, the copper concentrate and a silica material known as a flux are fed into a Vanyukov furnace. The concentrate and flux melt and make the matte, comprising copper, iron and sulphur that settles at the bottom of the furnace. The rest of the iron chemically combines with the flux to form a slag, which can be separated off.

Get Price -

Jaw Crusher

The 911MPETMBT75 is our largest Laboratory Jaw Crusher and is based on our worldrenowned High Reduction Ratio Jaw Crusher, the 911MPETMBT75 has been engineered to handle the toughest crushing an input gap opening of approximately 71/2" x 71/2" ( 191 mm x 191 mm), this machine will crush larger rocks and/or any other dry material faster than any other Jaw Crusher .

Get Price -

Frontier Mine A copper sulphide concentrate ...

A copper sulphide concentrate producer. Frontier Mine is a cornerstone of ERGA's copper business, situated on the DRCZambia border, 30km north of Ndola, with access to stable infrastructure in terms of road, rail and power networks. Frontier Mine comprises an opencast copper mine and processing facilities to produce copper sulphide concentrate.

Get Price -

FL wins fourth Copper Concentrator Order in ...

Feb 22, 2018 · Valby, Denmark – KAZ Minerals in Kazakhstan has selected FL as their technology partner for a new, 75,000 tonnes per day copper concentrator line at Aktogay. FL's scope of supply includes the key machines, installation supervision, commissioning, startup and rampup support. The total order value is more than USD 100 million.

Get Price -

Projects – Oman Mining Company

The blister copper was finally fire refined in an anode furnace, blown successively with air increasing the copper grade and the copper was cast into anode. The slag produced in the Smelter was sold to a local company. The smelter plant was designed to treat 80 000 tonnes of copper concentrate annually.

Get Price -

Crushing Process For Copper Ore Crusher Machine Supplier ...

Copper ore crusher is mainly used copper ore crushing equipment is the main raw material processing copper ore and refined copper products copper ore after crushing and screening, grinding, magnetic separation, drying and other procedures gradually election the copper concentrate shanghai sbm production of portable copper ore crusher machine .

Get Price -

Copper Ore Crushing Grinding Equipment Used For Dominica

Copper Ore Processing Equipment. Capacity: (m ³/min) Suitable Materials:Copper, zinc, lead, nickel, gold and other nonferrous metals, ferrous and nonmetal. View Details Send Enquiry Ceramsite Production Line. Production Capacity:705,000 t/d

Get Price