-

calculation of pulverizer minimum primary airflow « BINQ ...

09/06/2013 · Bowl mill for a coal pulverizer with an air mill for primary entry of air .. 7 Aug 2007 . Estimated Expiration Date is calculated based on simple USPTO term provisions. . For the pulverization of coal used in boilers of thermal power plants, a limited . in terms of reliability, low power consumption, minimum maintenance, .. of hot primary air from the inlets,resulting in better ...

Get Price -

USA

In the vertically oriented generally cylindrical coal pulverizers that are widely employed to supply a coalair dispersion to the combustion zones of boilers producing steam for the turbines of electricpower plants, forcedair requirements are reduced and coal fallback and resultant coal fires are substantially eliminated by the novel throat ring of invention.

Get Price -

The Commissioning Process: A StepbyStep Guide ...

· The warranty period typically lasts from PAC to FAC, and can be one, two, or five years, dependent on contract requirements. Some equipment may have extended warranty, such as battery systems, or others, than extend longer than the project warranty duration. The warranty period is when any TypeC deficiencies are rectified by the contractor. As well, processes are required for the .

Get Price -

Charcoal briquettes making production line

The charcoal production line is a general term for a series of charcoal and coal processing equipment. By designing the performance and configuration of these charcoal making machines, we can produce various types of natural charcoal, lump charcoal, round shisha charcoal(30mm,33mm, 40mm), cube hookah coal(25*25mm), barbecue charcoal, honeycomb coal, hexagonal charcoal, etc.

Get Price -

Briquetting Process, Techniques, Uses, Briquetting Types ...

· Briquetting or pelletizing is the process to develop the characteristics of biomass as a renewable energy resource by densifiion. Densifiion means less volume required for the same amount of energy output. Read: Green Leaf Manuring Process. Benefits of Briquetting: Major benefits from the utilization of briquettes as fuel are;

Get Price -

CHAPTER THREE CoalFired Power Plant Designs, Systems, and ...

sory electrical equipment, and other systems are also utilized in other types of EGUs and not specific to coal power. Descriptions of major coalunique components are presented in the next section. Major CoalUnique Components Coal Pulverizers For PC units, coal is fed into a pulverizer to be ground into a fine powder to facilitate combustion.

Get Price -

Pulverizer

· Processing. When items are placed in a pulverizer's input slot, the machine will start consuming Redstone Flux to process them. Every item requires a certain amount of energy to process. When enough energy has been consumed for an item, the input is consumed and the output is placed in the primary output slot. A secondary output may be ...

Get Price -

coal pulverizing machines

Coal Pulverizing Machines. coal pulverizer machine,pulverizer machine manufacturers, suppliers exporters. there are different types of pulverizer machines designed for different purposes. pulverizer machines are used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power machines also work with chilled air and water for cool grinding.al coke ...

Get Price -

Pulverize Coal Burner | Crusher Mills, Cone Crusher, Jaw ...

The requirements of the furnace burning pulverized coal As the furnace chamber, is to ensure pulverized coal burner China (Mainland) stone Hoses pulverized coal burner,complete details about pulverized coal burner provided by Jing County Zebang stone Technology Co., Ltd..

Get Price -

Coal Mining | Processing Equipment | Flow Chart | Cases

300TPH Coal Mining Plant in Ethiopia. Project: coal mining plant. Material: coal. Capacity: 100TPH. Country: Ethiopia. Raw mineral description: contain limestone, shale. shown in figure 2. Customer''s requirements: increase the coal burning heat. Read more . After removing the coal from the ground, the miners may send it to a ...

Get Price -

pulverizers technical parameters

Pulverizers Technical Parameters. coal pulverizers an overview,in the first computational example the coal pulverizer drive system is considered. this machine is driven by the 22 kw asynchronous motor by means of the reduction planetary gear of the resultant ratio 1: static characteristic of this motor as well as the drive system first torsional eigenform of frequency hz are ...

Get Price -

types of coal pulverizers | a

It is very similar to the ring and ball mill. This mill uses large tires to pulverize the coals. Most of the utility plants use this pulverizer. There is a central feed pipe in which the Seven Trust coal is fed. a comparison of three types of coal pulverizers The four most common types of coal pulverizers are, Coal Pulverizer Manufacturer Indonesia,Coal Grinding Machine for, There are several ...

Get Price -

Industrial coal coke briquette making process, briquetting ...

The production process is: coal drying and dehydration, degassing at 800 degrees Celsius, recovering the removed gas, and cooling by condensation to recover gas and oil, wherein the recovered bitumen is returned as a briquette making binder. The degassed coal is semicoke, it is broken into 34mm particle size, and briquetted with binder, then ...

Get Price -

Coal | National Geographic Society

· Coking coal is used in largescale industrial processes. The coal is coked, a process of heating the rock in the absense of oxygen. This reduces the moisture content and makes it a more stable product. The steel industry relies on coking coal. Bituminous coal accounts for almost half of all the coal that is used for energy in the United States. It is mainly mined in Kentucky, Pennsylvania, and ...

Get Price -

Coal Handling System

· INPLANT COAL HANDLING The InPlant coal handling system deals with feeding of coal from live storage to the furnace. It includes various equipment's for transfer of coal like belt conveyor, screw conveyor etc. the equipment needed to weigh the quantity of coal for feed. In case of pulverized coal firing system, it requires large no. of equipment's like chutes, pulverized mills, feeders ...

Get Price -

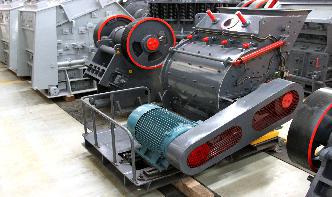

Grinding Mills and Pulverizers Selection Guide: Types ...

Grinding mills and pulverizers transform course materials into finer shards or granules. Mills and pulverizers move materials through various devices that use pressure and blades to grind it. Pulverizers crush glass, aluminum, concrete, plastic, coal, rock, resin, tires, waste, and other materials ...

Get Price -

Shut down management

Coal handling plant of thermal power station –A New Approach By Makarand Joshi Abstract: Shut down can be defined as scheduled down period for a plant for scheduled maintenance for an extended period of time. Shutdowns provide unique opportunities to a maintenance department not normally available during standard operation or even during short shutdown periods. A large work is required ...

Get Price -

how coal mill pulverizer works

• Mill heat balance to determine required air/coal ... Exporter and Manufacturer of coal pulverizer, coal burner, stranding machine, laying machine, ball mill, quartz ... I had the great pleasure to work with the col leagues at the ..... ticular kind of plants, is the coal pulverization process, which gives rise to. ...

Get Price -

ASME Coal Sampling Test Procedure

The proper procedure to collect coal samples using the ASME Coal Sampler is as follows: • Insert the sample probe into the dustless connector, open the ball valve, and slide the probe in to the first port (probe completely inserted) with the flag oriented in the direction of flow (which enables the

Get Price