-

Cement Industry

Salah M. El Haggar, in Environmental Solutions, 2005 Cement Industry. The cement industry is one of the main industries necessary for sustainable development. It can be considered the backbone for development. The main pollution source generated from cement industry is the solid waste called cement bypass dust, which is collected from the bottom of the dust filter.

Get Price -

Concrete: the most destructive material on Earth | Cities ...

· After water, concrete is the most widely used substance on Earth. If the cement industry were a country, it would be the third largest carbon dioxide emitter in the world with up to tonnes ...

Get Price -

The Environmental Impact of Recycled Concrete

Concrete is a building material used worldwide and consumes large amounts of raw materials. The concrete structure is cheaper than steel structures; the raw materials can be found in almost anywhere and can be moulded easily. Nevertheless, the concrete industry produces a lot of waste and the old concrete many times goes to landfills.

Get Price -

Study assesses cost savings of use of captured CO2 in ...

· Spain/Norway: A team from Cartagen Polytechnic and Ostfold University College has demonstrated that Cementos La Cruz could reduce the cost of its concrete production by /m3, or Euro29,000/month by curing concrete with captured CO has reported that the use of CO 2 would reduce the amount of cement required by 7 – 8%. . This in turn would remove an .

Get Price -

Costs Of Different Equipments Used In Cement Grinding

· Costs of different equipments used in cement indus. crushing grinding screening equipment mobile crushing plant crushing equipment grinding mobile crusher crushing equipment grinding mill crushing and screening plant grinding plant sand making plant there is a leading place for us in global mining machinery because of high efficiency low costs and good environmental effect in .

Get Price -

Understanding How The Indian Cement Industry Works

Understanding How The Indian Cement Industry Works. In this post, Ashwini Damani Pradeep Jaiswal write on how cement industry in india works what should be the parameters while analyzing any cement company. Ashwini is a chartered accountant CFA. He has worked with Lafarge, one of the largest cement players in India for more than 6 years.

Get Price -

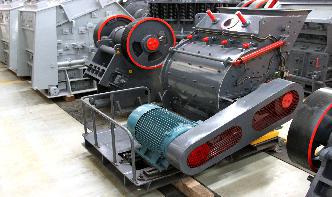

4 Types of Stone Crushers' Maintenance and Efficient ...

· There are different types of stone crushers in mining industry such as jaw crusher, cone crusher, impact crusher, and sand making machine. This article will tell you how to maintain the 4 types of rock crushers and how to efficicently improve their performance.

Get Price -

Type 1 Recycled Crushed Concrete

Crushed Concrete is one of the most versatile products that we stock here at Primarily used by clients in the construction industry for purposes such as sub bases and roads, crushed concrete is a costeffective aggregate that you can use for an extensive range of appliions.

Get Price -

Industrial Solutions Gyratory crushers

Industrial Solutions Gyratory crushers Stateoftheart technology with throughput rates of up to 14,000 t/h

Get Price -

Components Crusher Used Cement Industry

Components Crusher Used Cement Industry. Sie of raw meal used in cement plant cement mill process plant handbook pdf Solutions for the Cement Industry Mills raw meal mill Vertical Roller Mill in Cement Raw Mix Cement mill Wikipedia A cement mill or finish mill in These have been used for many years for the less exacting rawmilling process The cement mills .

Get Price -

(DOC) Project Report On Stone Crusher Plant Stone crusher ...

Project Report On Stone Crusher Plant Cost of Project: Rs. 5, 00, 00, CHITTALAX CONSTRUCTION PRIVATE LIMITED Place of Business: Mangalvedha Tq Mangalvedha Dist. Sholapur fSTONE CRUSHER PLANT 1. INTRODUCTION Stone Crushing Industry is an important industrial sector in the country engaged in producing crushed stone of various sizes ...

Get Price -

Sand and Gravel Prospect and Price in Philippines |

· Equipment used for crushing and sandmaking includes vibrating feeder, jaw crusher, impact crusher(for soft ores like limestone) or cone crusher(for hard ores like river stones), sand making machine, vibrating screen, sand washing machine. Main equipment and configuration taking 100120 tons/h of river stone crushing line as an example:

Get Price -

Hammer Mill Operating Principle

· The large, heavy duty crushers are frequently used in such industries as carbide, chemical and cement as a primary machine where large capacities and cubical products are desired. The Jeffrey Heavy Duty Reversible Hammer Crusher is designed especially for reducing bituminous coal down to a product of 85% minus 1/8″, at large capacities, for coking purposes.

Get Price -

MODEL PROJECT REPORT

Improving crushing strength of extruded products (200 to 300 kg/cm2) Resource savings – Energy (up to 20%) and top soil (up to 30%) Reduction in masonry costs and plaster requirements Reduced cooling/heating load requirements. Present Scenario As mentioned in the introduction, most of the brick kiln entrepreneurs use

Get Price -

Small Rock Crusher for Sale, Mini Stone Crushing Machine ...

They can be used with the cement making machine. Small rock crusher can move (though usually is very heavy), and it also can be fixed. Small Rock Crusher Market Analysis: As China's economic construction is growing, the domestic real estate and highspeed way construction develops rapidly, which make small rock crusher industry has a rapid ...

Get Price -

Green hydrogen for grey cement

· Hydrogen and its use in cement production has been adding a dash of colour to the industry news in recent weeks. Last week, Lafarge Zementwerke, OMV, Verbund and Borealis signed a memorandum of understanding (MOU) to plan and build a fullscale unit at a cement plant in Austria to capture CO 2 and process it with hydrogen into synthetic fuels, plastics or other chemicals.

Get Price -

A Review of The Use Of Recycled Materials in Rigid Pavements

Although recycled crushed concrete is used in pavements, the use of recycled crushed brick in pavement subbases has been limited because of lack of standardized guidelines or performancebased specifiions for recycled crushed brick. Another material that can be used is Cement kiln dust (CKD).

Get Price -

Industrial Concrete Stone Crushers | Murrysville Machinery

What Industrial Crushers Are. Crushing equipment reduces large materials into a smaller size. A typical impact crusher or other type of rock crusher uses a great deal of force to reduce the size of rocks. They operate on mechanical force for breaking apart the large rocks as opposed to chemical or laser methods of breaking rocks.

Get Price -

INCREASING THE USE OF ALTERNATIVE FUELS AT CEMENT PLANTS ...

Cement accounts for at least 5 percent of anthropogenic emissions of greenhouse gases, and, according to some estimates, this share may be even higher. At the same time, energyrelated expenses in the cement sector, mostly on fossil fuels and electricity, account for 30 to 40 percent of the industry's cash costs. While current energy prices are

Get Price -

Concrete vs Cement: Understanding the Fundamentals

· Cement can be made from a variety of materials, but it can't be used on its own. In fact, Roman cement was crushed rock with burnt lime, volcanic ash, and brick supplements. Today, Portland cement is the most common cement used and is one of the lowest cost materials around the world due to the widespread availability of limestone and shales.

Get Price -

Crushing Plant Design and Layout Considerations

primary crushing plant on solid rock reduces the cost of concrete and structural steel. Life of Mine/Expansion Plans The life of the mine is a key element in the design of any crushing plant. Shortterm mine lives (three to eight years) require a very careful approach to .

Get Price -

SoilCement

Soilcement pavements have many uses from city streets, county roads, state routes, and interstate highways, to parking lots, industrial storage facilities, and airports. In fact, the "family" of soilcement pavement products can actually be divided up into three main components – each with their own unique contribution to a pavement structure.

Get Price -

Cement Crusher Use

Cement Crusher Use. Difrent type of crusher use in cement plant complex cement challenges road used mobile concrete crushers for sale rock crusher mill used types such limestone crusher in cement industry limestone crusher in cement crusher,rock crusher,mining equipment, group is a stone crusher.

Get Price -

Lime Production: Industry Profile

the lime manufacturing industry provides information to be used to support the regulation. Lime manufacturing falls under the Standard Industrial Classifiion (SIC) code 3274 (NAICS 32741). According to the 1997 Census of Manufactures, 85 establishments owned by 47 companies manufactured lime in 1997 ( Department of Commerce, 1999b).

Get Price -

Preheater In Cement Plant, Cyclone Preheater, Cement ...

Production Capacity: t/d. Get Price! The cyclone preheater, also called cement preheater, suspension preheater, is a kind of preheater in cement plant. As the core equipment of dry method cement production line, cyclone preheater use suspension preheating to preheat and partly decompose the cementraw mix, shorten the length of rotary ...

Get Price