-

Hammering and Forging Safety Guidelines

Goldsmiths and silversmiths use hammers frequently in their work, silversmiths especially. A regular trade goldsmith might use a bench hammer with a ring on a mandrel twenty or more times a day. Blacksmithing operations use coal fires, gas torches and kilns. View these Hammering and Forging Safety Guidelines for your safety. Hazards

Get Price -

example example appliion of hammer mill

appliion on hammer mill ekhayawhiteriver. Then again, ERDWICH hammer mills also take the pelletisation of rubbery great example of the product's flexibility in ering to a wide range of appliions. Get Price. Appliions for Hammer Mill Operation Ottinger Machine Company. Appliions for Hammer Mill Operation.

Get Price -

Electric Wood Hammer Mill for Sawdust Making

CF500B wood hammer mill. Features and Advantages of Electric Wood Hammer Mill. 1. Electricitysaving: the smallest wood hammer power is only, best choice for home use. 2. Safe to operate, low noise, stable working. 3. Low malfunction rate, easy to operate and low maintenance cost. 4.

Get Price -

How it Works: Crushers, Grinding Mills and Pulverizers ...

· · Hammer mills are a type of impact mills that utilize fixed or swinging hardened steel hammers, chain or a cage. Hammer mills can be used for coarse crushing or fine grinding, depending on the size and configuration. Hammer mills are available in vertical and horizontal rotor configurations with one to many rows of hammers.

Get Price -

Design and Development of a Petrolpowered Hammer mill for ...

A conventional hammer mill is a device consisting of a rotating head with free swinging hammers, which reduce rock, grains or similarly hard objects to a predetermined size through a perforated screen, hammer mills can be used for grinding grain into fine flour or .

Get Price -

mining ore bergamasco double rotor hammer mill

Hammer Mill Operating Principle 911 Metallurgist. Mar 19, 2017 When minimum fines are a requirement, the hammer mill should always he as high as 20:1 in open circuit, and to double this performance in closed circuit. breaking of shovelloaded, quarryrun, or ROM minerun rock and ore. of the rotor in order to use the opposite unused faces of the hammers.

Get Price -

Understanding CNC Milling

A horizontal CNC milling machine (also known as a CNC mill) performing a milling operation on a metal part.. Image Credit: Andrey Armyagov. CNC milling, or computer numerical control milling, is a machining process which employs computerized controls and rotating multipoint cutting tools to progressively remove material from the workpiece and produce a customdesigned part or product.

Get Price -

How Does a Hammer Mill Work?

3. Hammer mills work in the principle that most materials will crush, shatter, or pulverize upon impact. 4. The Process: Material is fed into the mill grinding chamber through the feed chute, typically by gravity. It repeatedly is struck by ganged hammers which are attached to a shaft which rotates at high speed inside the mill chamber.

Get Price -

MILLING MACHINE OPERATIONS

MILLING MACHINE OPERATIONS OD1644 LESSON 1/TASK 1 discussed in this text. Keep in mind that although we are discussing a knee and a column milling machine, this information can be applied to other types. Use figure 1 on page 3 (which illustrates a plain knee and column milling machine) to help become familiar with the loion of the various

Get Price -

How Does a Hammer Mill Work?

Hammer mills work on the principle that most materials will crush, shatter or pulverize upon impact: The Process: • Material is fed into the mill's chamber through the . feed chute, typically by gravity. • The material is struck by . ganged hammers (generally rectangular pieces of hardened steel) which are attached to a . shaft. that ...

Get Price -

Milling Process, Defects, Equipment

Milling machines can also be classified by the type of control that is used. A manual milling machine requires the operator to control the motion of the cutter during the milling operation. The operator adjusts the position of the cutter by using hand cranks that move the table, saddle, and knee.

Get Price -

The Working Principle of Hammer Mills (Stepbystep Guide)

Hammer Mill. SaintyCo hammer mills are high precision machines for grinding solid and hard granules. Our hammer mills guarantee uniform grinding, noiseless operation and less heat buildup in all pharmaceutical processes. Whether you need standard or customized hammer mills, SaintyCo offers many series for specialized shredding appliions.

Get Price -

Feed Roller Mills for Cattle

Livestock Operation. Type of livestock : Cattle, Dairy, Poultry, Hogs, Horse, Goats, Sheep, etc. ... The SvenMill roller mills crack the grain instead of pulverizing it like a hammer mill. This allows for less fines and flour and more nutrition going to the animals.

Get Price -

Laboratory Mills

Hammer mills The hammer mills grind by means of a highspeed rotating steel "hammer" and has a sieve in the periphery through which the sample leaves the grinding chamber. By selecting different sieves, the particle size distribution in the sample can be varied. The hammer mill is typically used to produce a fine and homogeneous sample.

Get Price -

John 400 GrinderMixer Operators Manual

wide hammer mill with 20inch feed throat. The hammer mill has 26 fourway reversible, free swinging hammers, and 506 square inches of screen area. The grindermixer is PTO driven at either 540 or 1000 rpm and uses a 41/2inch wide, 24groove polyV belt. The drive is designed for a maximum of 80

Get Price -

Google Scholar

Google Scholar provides a simple way to broadly search for scholarly literature. Search across a wide variety of disciplines and sources: articles, theses, books, abstracts and court opinions.

Get Price -

FAM – Mills – Processing Technology

FAM Mills FAM designed mills are used for comminution with a fine or ultrafine target granulation. The types of mills are distinguished by their working principles: by pressure, impact, hammer, or shear. Mills could be equipped with a screen for grain size

Get Price -

SAFETY RULES BASICS FOR MILLING MACHINES

13. The best way to clean up the milling machine is using an air hose. A. True B. False 14. If you are uncertain about the setup or any aspect of the operation, you should A. go ahead and try the operation. B. check with your teacher before proceeding. C. call the .

Get Price -

APPLICATION OF HIGH ALLOY CAST STEEL MATERIAL ON THE ...

Hammer mill is one kind of machine that needs high durability, especially for grinding components such as hammers, which has a function to crush stone (mineral) in to fi nely shaped (mesh 80). So these components should be made from materials which have some properties, such as high strength, toughness, and wear resistance.

Get Price -

Pin Mill: Description, operating principles, advantages ...

· Advantages of Pin Mill. 1. It achieves smaller particle size than hammer mill at relatively reasonable energy consumption. 2. Recent advances have improved heat removal from the mill using cryogenic conditions. 3. Pin mill occupies little floor space. 4. It has a wide range of appliions; can be used in milling dry, moist or slurry materials.

Get Price -

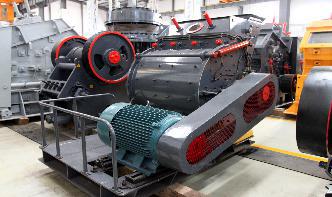

Hammer Mill Crusher Grinder

· The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these machines ...

Get Price -

Operation Hammer Strike Strikes Again; Over 60,000 Illicit ...

· Operation Hammer Strike Strikes Again; Over 60,000 Illicit Cannabis Plants Seized in Weeks Seven and Eight. Officials eradied 319 greenhouses, six indoor grow facilities, and one THC extraction lab in a twoweek period of the investigation.

Get Price