-

What is the difference between volumetric and gravimetric ...

Asynchronous systems (C), on the other hand, first measure the material before mixing and then feed it to the process in a separate step. An example from around the home clearly illustrates the difference between volumetric and gravimetric measurements: 250 ml of liquid cream will become around 1000 ml when whipped – but its mass will remain constant at 250 grams. Whether you use a ...

Get Price -

What is the difference between volumetric and gravimetric?

· Volumetric Feeder. Volumetric feeders supply a certain volume of material per unit of time. Known volume units of a particular material are used for the volumetric measurement and the material is transferred to a massbased discharge using scanned calibration. Feeding is changed by adapting the auger speed. What is meant by the term gravimetric ...

Get Price -

Schenck weigh feeder calibration procedure

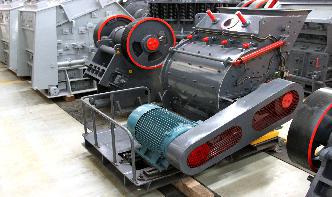

Schenck weigh feeder calibration procedure Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Schenck weigh feeder calibration procedure, quarry, aggregate, and different kinds of minerals. We can provide you the complete stone crushing and beneficiation also ...

Get Price -

MGF Gravimetric Feeder | Maguire Products

Maguire Gravimetric Feeders eliminate manual handling and mixing and reduce operation costs. Save typically 30% on masterbatch costs compared to manual or volumetric dosing. Twin Load Cells. Lightweight aluminum hopper mounted on 2 load cells which measure the weight of the hopper and the material ONLY. Continuously monitors the lossinweight as material is dosed and automatically .

Get Price -

Should coalfired power plants use gravimetric feeders?

· Substituting a gravimetric feeder with a volumetric equivalent isn't feasible for power plants. Machinery that burns coal to produce a specific amount of energy must not receive an excess or paucity of material. If a pulveriser, for example, receives more coal than it is equipped to handle, the mechanism may break, resulting in downtime and lost productivity.

Get Price -

schank calibration procedure of weigh feeder

· Also the gravimetric feeder of the calibration checking system according to the present ... parameters for coal weigh feeder calibration; weigh feeder working principle pdf; schenck belt weigh feeder installation manual; weigh feeder working principle ppt ; working principle of schenck weigh feeder; how many cement in 1 m3 cc; gold milling machine for sell in uk; graphite identified in a ...

Get Price -

Dust Sampling Instrumentation and Methods

· pDR Field Calibration • Divide average gravimetric concentration by average pDR concentration for same sampling period • Multiply all individual pDR readings by ratio • Example: gravimetric average = mg/m 3. pDR average = mg/m. 3 . grav/pDR ratio = / = . pDR concentrations * = adjusted pDR concentrations . pDR Provides Time Record of Dust Levels . .

Get Price -

How to Design Efficient and Reliable Feeders for Bulk Solids

Gravimetric feeders should be used whenever there is a requirement for close control of material discharge. Examples include when the feed rate uniformity must be better than ±2%, or sample collection times must be less than about 30 sec. A gravimetric feeder should also be used when the bulk density of the material varies. Criteria for Feeder Selection No matter which type of feeder is used ...

Get Price -

Gravimetric Feeders: The Achilles' Heel of Continuous ...

· Gravimetric feeders are frequently used in continuous manufacturing processes. A gravimetric feeder relies on a control system that adjusts the speed of the feeder based on lossinweight measurements. Since the controller is unable to discern the discharge rate when its hopper is being filled with new material, two hoppers arranged in series are typically used. The lower hopper is .

Get Price -

gravimetric coal feeder

· Weightsensor calibration for gravimetric coal feeder. Referring more particularly to the drawings and initially FIGS. 1 and 2, there is shown a gravimetric coal feeder A adapted to receive a column 10 of particulate coal through an inlet conduit 11, from a hopper 12. The apparatus A feeds the coal from the column 10 at a controlled rate of flow to a discharge chute or conduit 13 at the right ...

Get Price -

Monitoring and Optimizing Fuel Feed, Metering and ...

Gravimetric Feeder Functions • Load Cell feeders –Fixed height leveling bar usually high center –Weight on weigh span varies with material density –Calibration of load tare, load span and belt speed using optical probes –Calculation of feed rate (lbs/sec) by multipliion of belt speed (in/sec) by weight (lbs/in) –DCS demand signal adjusts material feed rate –Microprocessor ...

Get Price -

How to Troubleshoot Your Feeder to Achieve Optimal ...

· Unlike the volumetric screw feeder, a continuous lossinweight (LIW) feeder is a gravimetric feeder that directly measures the material's weight to achieve and maintain a predetermined feed rate that's measured in units of weight per time. The LIW feeder (see Fig. 2), consists of a hopper, refill device, weightsensing device (typically either a digital or analog scale or load cells ...

Get Price -

Gravimetric feeder for high dosing accuracy | Gimat ...

Gravimetric Feeders fall into 3 egories: Batch Feeders – by controlling weight a weighed batch (Kg) is dosed, cab be lossinweight or gaininweight. Rate Feeders – by controlling speed a variable speed rate (Kg/hr) is dosed. Recipe Feeders – by controlling both speed and time a variety of recipes can be delivered already mixed.

Get Price -

MODEL 496 NFPA® GRAVIMETRIC COAL FEEDER

MODEL 496 NFPA® GRAVIMETRIC COAL FEEDER COAL VALVES • Bunker Outlet Valves are designed to cut through a standing column of material • Knife Gate Valves provide "off on" control of material of varying sizes GENETIX PROCESS CONTROLLER Genetix® has the flexibility to accommodate both simple and complex system configurations. With Genetix® you can choose where .

Get Price -

How to Troubleshoot Your Feeder for Optimal Performance ...

Gravimetric feeder that directly measures the material's weight to achieve and maintain a predetermined feed rate. Gravimetric feeder with ActiFlow technology. ActiFlow bulk solid activator for gentle and adaptive ingredient flow. LIW feeder performance is dependent on three factors that are closely linked The mechanical configuration of the feeding device and any material flowaid used in ...

Get Price -

Feeders – Coperion

Single and twin screw feeders. Compact screw feeders are ideal for low feed rates. Highly accurate SFT load cells are at the heart of Coperion KTron lossinweight feeders. Smart Weigh Belt Feeders offer gentle handling of bulks solids. K4G Blending Stations allow multiple feeders to .

Get Price -

What are Coal feeders? Principle, components ...

· What are coal feeders? Coal Feeder is a device that regulates the amount of coal to be supplied into the Coal Mill. The amount of coal is regulated according to the needs in the boiler combustion chamber (furnace). The number regulation system in the coal feeder can be done in two ways based on the type, namely by weight fraction or coal volume ...

Get Price -

Schenck Process

Highpressure gravimetric feeder for coalfired boilers. The Stock highpressure gravimetric (HPG) feeder has been specifically designed for the utility and power industries. Its primary use is in pulverized coalfired boilers that require feeders that can withstand explosion pressures as high as The feeder also provides maximum safety and a steady flow of coal to the pulverizer ...

Get Price -

Engineering Technology

· The Gravimetric coal feeders calculates the coal flow by measuring the instantaneous weight of coal on the this the loadcell output (in mV) must be correlated with a standard this purpose we subject the loadcells to a standard weight and run the empty this condition the tachogenerators are measuring the speed of the belt .Simultaneously the speed of the .

Get Price -

A Beginner's Guide Introduction

If you move your instrument, then check calibration. If you shut your instrument down for a long period of time, then check calibration. Q How do I clean the TGA furnace? A The furnace is easily cleaned by having the furnace open to air and heating it up to 900 °C and burning all organic residue off the furnace. For the TGA 8000, there is a CLEAN Button on the software Instrument Control ...

Get Price