-

Introduction to Iron ore Pellets and Pelletizing processes ...

Feb 23, 2013 · Pelletizing is a process which involves mixing of very finely ground particles of iron ore fines having a size which is less than 200 mesh ( mm) with additives like bentonite and then shaping them into near oval/spherical balls having size in the range of 8 mm to 16 mm in diameter by a pelletizer and hardening the balls by firing with a fuel.

Get Price -

Process

Process. Both hematite and magnetite ore is processed appropriately before being sent to customers. The hematite ore undergoes mechanical processing (crushing, screening and blending). Primary and secondary crushing takes place at Zouerate, where SNIM .

Get Price -

HEAVY MEDIUM BENEFICIATING PROCESS

5. screening the fines float fraction of step (c) to produce a fines particle fraction and recirculatable water; 6. screening the fines sink fraction of step (f) to produce a sink particle fraction and recirculatable water. 7. The process of claim 1 in which the ore is coal. 8.

Get Price -

Ecoefficient and costeffective process design for ...

Feb 24, 2015 · The key objectives of the evaluation are as follows: Assessment of different ecoefficient comminution process circuits to treat magnetite iron ore. Determination of the process operating costs and the capital costs for each process route. Comparison of the benefits of the different process routes from an economics point of view.

Get Price -

Screening/Sifting Materials:........

Sep 23, 2021 · Screening/Sifting Materials: For pulverized dry granulated materials. Our Fine Powder Sifting Systems are amongst the most efficient on the market. Because thanks to the vibrations directly in contact with the sifting net. It guarantees high productivity and precise separation cuts. Screening/Sifting Materials: https://

Get Price -

Iron Ore Agglomeration Technologies | IntechOpen

Dec 20, 2017 · The process consists in: part of fine grained iron ore is transformed into 8–16 mm green pellets, while the rest and the coarse fine ores are mixed with fluxes, fuels and return fines, and then granulated (primary mixture); green pellets and primary mixture are blended (secondary mixture) and then fed to the sintering machine; the mixture is ...

Get Price -

What is the texture of magnetite?

Apr 08, 2020 · A general processing circuit for magnetite ore is initial crushing and screening of run of mine (ROM) ore to <6 mm. The ore is then milled to a specified grind size to liberate the iron minerals from the gangue, then processed further to produce a magnetite concentrate, commonly by a wet magnetic separation process .

Get Price -

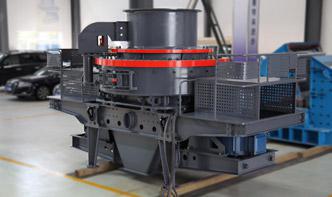

Crushing and Screening for Mineral Processing Success

A double deck screen is the correct choice for this appliion so particles that are too big for sorting are sent back to the cone crusher, and particles that are too fine are removed. The screen panel openings for the two decks need to be sized correctly to ensure the success of both jobs. Finally, the screen area size should also be sufficient.

Get Price -

Magnetite: South Australia's potential

A general processing circuit for magnetite ore is initial crushing and screening of run of mine (ROM) ore to <6 mm. The ore is then milled to a specified grind size to liberate the iron minerals from the gangue, then processed further to produce a magnetite concentrate, commonly by a wet magnetic separation process.

Get Price -

(PDF) Recovery enhancement of magnetite fines in magnetic ...

Eng. Aspects 232 (2004) 151–154 Recovery enhancement of magnetite fines in magnetic separation Arol a,∗, A. Aydogan b a Middle East Technical University Mining Engineering Department, Ankara, Turkey b Ministry of Energy and Natural Resources, Ankara, Turkey Accepted 23 June 2003 Abstract Low intensity wet magnetic separation is not ...

Get Price -

Major Mines Projects | Iron Bridge Project

The Iron Bridge incorporat the world class North Star and Glacier Valley Magnetite ore bodies, the innovative process design, including the use of a dry crushing and grinding circuit. The Iron Bridge project includes the installation of a 135km concentrate slurry pipeline to Port Hedland, together with a return water pipeline.

Get Price -

Dressing Ways for 3 Kinds of Iron Ore Make You Profitable ...

Jul 12, 2021 · The magnetite in the ore is embedded with medium to fine grain. Gangue has silie or carbonate minerals, often accompanied by pyrite, cobalt pyrite or chalcopyrite, and apatite. Generally, lowintensity magnetic separation and flotation are combined to separate the iron minerals from ores.

Get Price -

Composition Ofmagnetite Ore Before Processing Processing

hematite ore processing. Magnetite ore is suitable for processing into iron ore ... Iron ore beneficiation is the process of purifying raw iron ore before ... fine grain,complex composition.

Get Price -

Screening and Classifiion

Screening, classifying and dewatering are processes which aim to improve downstream separation and materials (particularly product) handling. Most separation processing benefit from a closely sized feed, since it will reduce the effect of particle mass and allow whichever physical charactoristic being utilised to be the dominant physical force ...

Get Price -

Major Mines Projects | Lake Giles Project

Hence, in order to achieve Mtpa of magnetite concentrate, the amount of ore feed to the magnetite process plant (concentrator) is Mtpa. Additionally, a waste/low grade to ore strip ratio of 3:1 for magnetite has been assumed based on cross sections through the Moonshine deposit and :1 for hematite has been calculated based on ...

Get Price -

magnetite separator, magnetite iron ore processing ...

A magnetite in Inner Mongolia, the main mental mineral was magnetite with disseminated structure and fine particle distribution. The iron content was about 1216%. This plant adopted the grindingweak magnetic process and obtained 65% concentrate grade and 90% recovery rate, but the operation cost is too high after a long time running.

Get Price -

Iron Ore Pelletizing Process: An Overview | IntechOpen

Jul 11, 2018 · The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking. This chapter shows the status of the pelletizing process ...

Get Price -

Raptor® Screening Archives

Screens, Washes, Compacts and Dewaters . Trusted by municipal and industrial users alike, our Raptor® screening products are designed to effectively screen, wash, compact and dewater captured debris in one smooth, seamless operation. These screening products are all stainless steel construction and designed to combine 4 unit processes into one unit.

Get Price -

PROCESS FOR BENEFICIATING MAGNETITE IRON ORE

1. A process for beneficiating lowgrade magnetite iron ore containing no more than about to percent magnetite to facilitate onland disposal of tailings, which process comprises: 2. A process according to claim 1 further characterized in that: 3.

Get Price -

Screening

Screening is the first operation at any wastewater treatment works. This process essentially involves the removal of large nonbiodegradable and floating solids that frequently enter a wastewater works, such as rags, papers, plastics, tins, containers and wood. Efficient removal of these constituents will protect the downstream plant and ...

Get Price -

The Print Guide: FM/Stochastic Screening

Jan 17, 2010 · Halftone screening in the range of 65175 lpi is very tolerant of process variations however as the dots get smaller, process controls need to be tighter. That being said, the process controls that need to be in place for FM screening to succeed are no different than those needed for an efficient 175 lpi print manufacturing process.

Get Price -

Iron Ore Mining Magnetite Process

Iron Ore Mining Magnetite Process. Hematite magnetite mining process magnetite to hematite process ellul nl feb 24 2015 ecoefficient and costeffective process design for magnetite iron ore currently the mining industry is facing several issues related to energy consumption so the optimized use of energy is an everincreasing need.

Get Price