-

Iron ore grinding machines,ball mill for iron ore grinding ...

Ball mill for iron ore grinding plant . Ball mill is one of the most old flour mill equipments, which is one of the earliest flour mill that was applied in iron ore grinding field. We are one of the the most professional manufactures of ball mill in the world, our products .

Get Price -

mining ore iron ore plant for sale mexico

mexico iron ore mining process Mobile Gold Processing Plants,Ball . 14, 2013 photo, Mexican army soldiers enter the iron ore mine in the town of the sales of iron ore generated by Ternium Mining operations in Mexico, the. Chat

Get Price -

Major Mines Projects | Lac Otelnuk Project

Each SAG mill is designed for a fresh iron ore feed of 1,755 t/h. The calculated required power for each SAG mill is MW. The SAG mill dimensions are m (40 feet) diameter and m equivalent grinding length (EGL), which is the biggest size of proven technology operating today.

Get Price -

Apurimac Iron Ore Project, Andahuaylas, Peru

The Joint Ore Reserves Committee (JORC) compliant resources at the Apurimac iron ore project are estimated at million tonnes (Mt), including of indied mineral resource grading % Fe and of inferred resources grading % Fe. .

Get Price -

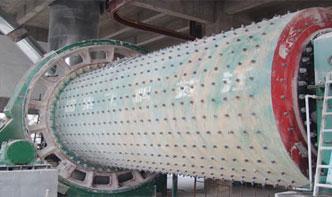

Ball Mill

Ball Mill. We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding appliions. Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirements.

Get Price -

Iron Ore Processing Line

The Major Equipment of Iron Ore Processing Line: Iron ore processing line includes vibrating feeder, jaw crusher, impact crusher, hammer crusher, round vibrating screen, ball mill, spiral classifier, flotation separator, magnetic separator, shaking table, jigger, spiral chute, concentrator, rotary dryer, rotary kiln, etc.. The Performance Characteristics of Iron Ore Processing Line:

Get Price -

Iron Ore Pelletizing GrateKiln System Brochure

Plant overview GrateKilnTM iron ore pelletizing system The first GrateKilnTM system pellet plant was installed in 1960. The plant took iron ore concentrate and produced superior iron ore pellets (which are spheres of high iron content and uniform quality) for blast furnace and direct reduced iron feed. Since then, GrateKiln systems have been used for over 50 plants, on both magnetite and ...

Get Price -

Iron ore pelletizing

Outotec iron ore pelletizing plants have a faster start up and better reliability than other plants in the industry. Iron ore can be upgraded to a higher iron ore content through beneficiation This process generates iron ore filter cake which needs to be pelletized to be used in the steel making process.

Get Price -

Iron Ore Smelting Process

Mar 13, 2010 · At the surface iron ore processing plants, the iron ore is put through crushers and ball mills to break it into a uniform and more workable size and then washed with the residue going to tailings. The ore is the transported to the various smelters loed locally or on the other side of the world with large bulk carriers being used to ship the ...

Get Price -

Iron Ore: Mineralogy, Processing and Environmental ...

Jul 24, 2015 · Iron Ore: Mineralogy, Processing and Environmental Issues summarizes recent, key research on the characterization of iron ores, including important topics such as beneficiation (separation and refining), agglomeration (, production of pellets or powders), blast furnace technology for smelting, and environmental issues relating to its production.

Get Price -

Industrial Mineral Processing Plant

Industrial Mineral Processing Plant. We are one of the leading manufacturer and exporter of Mineral Ore Beneficiation Plant Machines, fabried from superior quality of raw plants machines, specially designed for highest pressure performance, and are used in an assortment of of the features of these plants and machines are precision functionality, optimum ...

Get Price -

mining technology: Iron Ore Processing for the Blast Furnace

May 10, 2009 · The iron ore concentrate is now mixed and ready for the pelletizing process. Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a .

Get Price -

Ball Mill Iron Ore Processing Method Ball Mill Mine Equipments

Ball Mill Processing Iron Ore. Iron Ore Ball Mill Processing. the crushed ore is first transported to the coarse ore stockpile by conveyor belts, then fed to each of the six parallel milling lines using apron feeders and conveyor beltsach of the milling lines consists of a primary autogenous ag mill and a secondary ball mill.

Get Price -

Hazard Identifiion, Risk Assessment, and Control ...

The study was carried out in a 4m tonne iron ore pelletizing industry loed in Odisha, India from March to December 2015. The pellet plant used travelling grate technology to convert low grade fines into valueadded pellets. The slurry was received at the pellet plant from the beneficiation plant through a 220km pipe line.

Get Price -

how to form curved cement steps,performance analysis of ...

Laos iron ore processing plant Laos became one important Southeast Asian market of SBM since 2005, two years later after the Austria SEPON gold ore processing plant started to work. Owe to our good publicpraise, more and more Laos customers prefer to cooperate with SBM, and one SBM demo project—one 300TPH iron ore processing plant—begin to ...

Get Price -

Iron Ore Crushing Plant

Iron ore materials will be crushed by crusher machines and then separated by the magnetic separator which will separate the iron ore from the gangue minerals. After the iron ore cone crushing plant, the crushed particles are moved to secondary crushing and the first ball mill grinding stage. With fine ore particles, it is more efficient to ...

Get Price -

250TPH Iron Ore Processing Project in Zambia

250TPH Iron Ore Processing Project in Zambia According to customer's requirements of the capacity and Output size, We recommend YG1349EW8 and Y3S2160HP220 (EC) Mobile crushing plants. Main equipment such as European type jaw crusher and multiple cylinder hydraulic cone crusher are our most advanced machines which of high performance, big ...

Get Price -

Iron Ore Facilities :: ClevelandCliffs Inc. (CLF)

Iron ore is a major raw material required in the manufacturing of steel. Ironbearing pellets are shipped to ClevelandCliffs' Indiana Harbor facility in East Chicago, Indiana. In 2019, Minorca supplied about 50% of Indiana Harbor's No. 7 blast furnace's pelletized iron requirements.

Get Price