-

Cement production clay crusher

Cement production clay crusher Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Cement production clay crusher, quarry, aggregate, and different kinds of minerals.

Get Price -

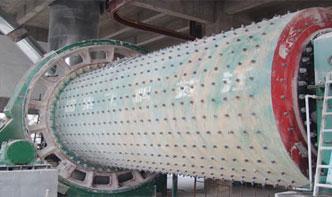

china ball mill for cement

China Grinding Mill Machine with Various Type China Ball ... Mills are widely used in the fields of metal separating factory, metallurgy, chemical industry, construction material, power generation and etc., for grinding of kinds of minerals and rocks, and include overflow type of ball mills, grid type of ball mills, rod mills, material mills and cement mills.

Get Price -

Asphalt Milling, What is It Why Do You Need It | NVM ...

· Since it began over 30 years ago, asphalt milling has become one of the quickest, easiest, and most affordable ways for business owners and installation managers to maintain safe, attractive, and healthy pavements. In many cases, milling is a better alternative to complete demolition or other costly pavement removal processes.

Get Price -

Mortar: what are my mixing quantities? | Clay Brick ...

Mortar: what are my mixing quantities? Mortar must not be used after it has started to set, which usually occurs about two hours after it has been mixed. One man – particularly if he is a weekend builder – can probably lay a little more than 60 bricks an hour. If you are working on your own or with one assistant, it is better to mix a number of small batches as they are

Get Price -

(PDF) Sample Preparation for XRay Diffraction Analysis

than that of othe r mills, for ex ample ba ll mills. Appliion reports which mention the Mc Crone M icroniz ing Mil l: [1] Srodon et al . 2001, Clays and Clay Minerals, Vol. 49, No. 6, 514 528

Get Price -

How to Make Clay Bricks

Naturally white firing clay or ivory clay is used with chrome flour to form different shades of grey colour in your ceramic concrete or cement is used to achieve these colours however concrete is very limited in the shades of grey used and may not offer any .

Get Price -

Wenxian Temin Industrial Co., Ltd

Wenxian Temin Industrial Co., Ltd, which was founded in the year 2009, is the leading manufacturer and supplier for block making machinery and plant, with more than 10 years experiences. Our main products:A, Hydraulic press brick machine1, autoclaved fly ash brick production line2, autoclaved sandlime production line3, hydraulic press brick machine 500T 4, hydraulic press brick machine 630T5 ...

Get Price -

CEMENT RAW MATERIALS

calcareous raw material) and clay, mudstone or shale as the source of most of the silica and alumina. Finished cement is produced by finely grinding together around 95% cement clinker with 5% gypsum (or anhydrite) which helps to retard the setting time of the cement.

Get Price -

Slate Roofs or Tile Roofs

· Roof tiles are human made, and the manufacturing process involves firing clay or concrete in a kiln. Because they are factorymade, the variety of roof tiles is much wider than natural slate, and the range of styles and colours available is vast. This can make a roof tile more appealing to those who have a specific shade or design effect in mind.

Get Price -

Fire and Explosion Hazards in Cement Manufacturing ...

Bag filters used for the coal mill rank as one of the highest fire and explosion hazards in cement plants, due to the small particle size of the crushed coal. 3) Electrostatic Precipitators Buildup of explosive mixtures like finely dispersed coal dust in air, or carbon monoxide in air can result in an explosion hazard in Electrostatic Precipitators.

Get Price -

Bulk Density Table

Clay (see bentonite, diatomaceous earth) (also Fuller's earth, Kaolin, marl) Clay, ceramic, dry, fines 60 80 Clay, calcined 80 100 Clay, brick, dry, fines 100 120 Clay, dry, lumpy 60 75 Clinker, cement (see cement, clinker) Clover seed 45 48 Coal, anthracite, (river calm) ... Mill scale (steel) 120 125 Milo, ground 32 36 Milo, maize (kafir ...

Get Price -

Pug Mills and Extruders for Clay

· Extruders and Pug Mills are VERY different machines. An extruder can be purchased for a couple hundred bucks, with lots of dies. A 4" barrel is about all one can handle without some type of mechanical reduction so you can press the clay through the die without weighing 400 lbs.

Get Price -

Using Lime Mud Waste from Pulp Mill as an Additive in ...

Lime mud from a pulp mill was used as an additive in brick clay from the southern part of Thailand. It was mixed with the clay from ChaAud district, Nakorn Sithammarat province. The chemical composition of lime mud and the clay was characterised by Xray fluorescence (XRF), and the mineralogical composition was measured by Xray diffraction (XRD).

Get Price -

Cement kiln

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant.

Get Price -

Pug Mills

Pug Mills The Ceramic Shop. When you run a largescale studio or classroom that goes through a lot of clay, recycling the scraps by hand is often not an option – the work can be laborious and timeconsuming, not to mention hard on the wrists and hands. This is the reason that pugmills are such coveted pieces of equipment for programs where ...

Get Price -

PUG MILLS — Venco

Clay is fed to the pug mill via a unique 'bucket feeder', eliminating the effort needed to pull a lever as with conventional pug mills. A novel twin auger mixing chamber, containing two counter rotating augers, quickly draws the clay away from the feed area and thoroughly blends it within the large volume, stainless steel, mixing chamber.

Get Price -

How To Recycle Clay

· You can recycle clay, or reclaim clay, so it can be used potters keep their non contaminated clay scraps from trimming, broken greenware, or old throwing slurry (3) to recycle and reuse. As long as clay has not been fired it can be recycled (10, 21). It can be a time consuming process (2), physically demanding and take up a lot of space (14) but it doesn't have to be an ...

Get Price -

SINTEF REPORT

However, the mineralogy of clays varies a lot, which may influence the reactivity. The optimum calcination temperature seems to be in the range 700800°C, even though it may approach 1,000°C in some cases. The benefit of replacing cement in concrete is not on strength improvement, but more on durability enhancement.

Get Price -

replacing mill in cement factory

Raymond mill is also called Raymond roller mill It is a new type of high fineness grinding mill with high efficiency and closed circulation which can completely replace the cement ball kind of machine is commonly used in cement plant for raw . Chat Online; Roller Mill For Cement Factory

Get Price -

Cement Manufacturing Process Flow Chart

The process of making cement is described in this flow chart. The two raw materials used in theprocess are limestone and clay. Limestone is crushed, sized, dried and stored in storage silos. In the same way, Clay is washed, crushed, and dried in storage basins. The two materials are mixed in the

Get Price -

Brick Masonry Material Properties

Technical Notes 3A Brick Masonry Material Properties December 1992 Abstract: Brick masonry has a long history of reliable structural for the structural design of masonry which are periodically updated such as the Building Code Requirements for Masonry Structures (ACI 530/ASCE 5/TMS 402) and the Specifiions for Masonry Structures (ACI /ASCE 6/TMS 602) advance the

Get Price -

Laguna Clay and Glaze Company | Clay | Glaze | United States

Welcome to the home page of Laguna Clay and Glaze Company. We are the industry leader in all things ceramic. Check out our world renounded clay and glazes.

Get Price -

Cement composition and classifiion

· Cement composition and classifiion. Almost all drilling cements are made of Portland cement, a calcined (burned) blend of limestone and clay. A slurry of Portland cement in water is used in wells because it can be pumped easily and hardens readily, even under water. It is called Portland cement because its inventor, Joseph Aspdin, thought ...

Get Price -

How to reduce vibration in milling

In face milling, use a small depth of cut, ap, and high feed, fz, with round inserts or high feed cutters with small entering angles. Avoid vibrations in corners by programming a large path radius, see milling inside corners. If the chip thickness becomes too low, the cutting edge will rub rather than cut, causing vibration.

Get Price