-

Characterization and Beneficiation of Anka Chromite Ore ...

CHROMITE ORE USING MAGNETIC SEPARATION PROCESS Abubakre 1, ... The beneficiation of the ore was carried out using magnetic separation technique. The results obtained after the chemical analysis of the beneficiated ore using Atomic Absorption Spectrometer shows that Cr 2O3 content increased to 48% with maximum Cr:Fe ratio of :1. The content of Cr 2O3 is high enough and can .

Get Price -

BENEFICIATION OF FINE ORES USING THE LONGI WET HIGH ...

Magnetic separation has been used since 1955 for processing a variety of minerals from iron ore in steel production to the desulphurisation of coal. The accumulation of such fines and slimes during mining operations and the increasing global demand for quality products

Get Price -

Iron Ore Processing

Key words : L ow grade iron ore, beneficiation, gravity, magnetic, sinter, pellet . 1. Introduction India is one of the leading producers and exporters of ir on ore in the world with over 28 billion tonnes of iron ore reserves [1]. P rocessing of low grade iron ore is inevitable as a r esult of increase in production and

Get Price -

Recovery of Iron Bearing Minerals from Beneficiation Plant ...

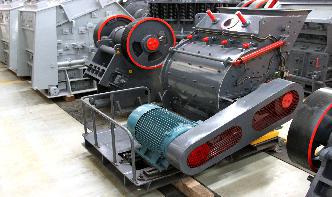

to beneficiate medium grade and low grade iron ore fines in the range of 58% to 61% Fe and 55% to 60% Fe re spectively. Beneficiation plant 2 circuits consist of crusher, scrubber, two stage classifier, spiral, and hydrocyclone and wet high intensity magnetic separator. During the beneficiation of low grade iron ore nearly 25% to 30% ( to Mtpa) of the material is disposed into the ...

Get Price -

SAIMM

· It also features in iron ore recovery circuits and the beneficiation of vanadiumbearing magnetite. Magnetic separation is important in the concentration and separation of ilmenite, rutile, and zircon, and is used for removing iron impurities from industrial minerals. As the name implies, this process entails separation of ore minerals from gangue on the basis of the difference in magnetic ...

Get Price -

Recent Technologies for beneficiation of Lean Iron Ores

ores are the main ones for which magnetic separation is applied. Magnetite and Chromitite ores (both iron ... fine particles of minerals. The process uses the ... Case study of a lean Iron ore's beneficiation from Goa mines is discussed below. 5a) The feed sample of

Get Price -

Advances in Low Grade Iron Ore Beneficiation

effective utilization of lowgrade iron ore and fines, through suitable beneficiation technologies. Although India is blessed with large reserves of iron ore, the performance of blast furnaces had been at lower levels. This has been mainly due to the presence of high levels of impurities in the feed material contrary to the blast furnace chemistry requirement. National Steel Policy aimed at a ...

Get Price -

Realtime slurry elemental analyser for iron ore ...

· Iron ore beneficiation plants are facing economic pressures to treat more challenging ore types, ... Influence of shear rate on separation of iron ore fines usin Automation for efficient separation with the Outotec SLon® v Dry processing of magnetic iron ores ...

Get Price -

IRON ORE

grade iron ore fines sample (10 mm) from iron ore beneficiation plant at Codli Mines of M/s Sesa Goa for RCOM, IBM, Goa. Fe Al 2 3 MgO TiO 2 Mn P LOI Val. Mineral Goethite, Limonite, Hematite, Martitised Magnetite Gangue Quartz, Clay, Mica, Gibbsite, Feldspar Fe Al 2O 3 SiO 2 LOI ...

Get Price -

EFFECTIVE PROCESSING OF LOWGRADE IRON ORE THROUGH .

Fatma et al. (1999) studied the beneficiation of an iron ore sample containing 44% Fe, % SiO 2 and 20% BaO. By magnetic separation, two products of iron ore and barite concentrates were obtained by using a high intensity magnetic separator. The fine fraction ( mm) is about 20% by weight assaying % Fe, and %

Get Price -

Technical Resource

· Statistical analysis and concentration of iron ore using Longi LGS 500 WHIMS A Longi LGS 500 wet high intensity magnetic separator (WHIMS) was used to concentrate a fine, low grade South African he...

Get Price -

Advances in Low Grade Iron Ore Beneficiation

iron ore is expected to rise by more than 200 million tonne per year to meet the internal demand export. This additional requirement of iron ore will need beneficiation of low grade ore/fines to get the major portion of increased demand. This paper deals in brief to use of available methodologies for beneficiation of iron ore in Indian context.

Get Price -

COLUMN FLOTATION FOR THE BENEFICIATION OF IRON ORE FINES

iron ore mines produce hematite ores and have washing plants to produce lumps as well as fines. During the washing process, around 810 million tons of slimes containing around 4860% of Fe are discarded every year.

Get Price -

Phase, Microstructural Characterization and Beneficiation ...

Beneficiation of the iron ore has been carried out by shaking table and magnetic separator. XRD analysis confirmed the presence of iron oxide (Fe 2O3) as the major phase along with quartz (SiO2) as the minor phase. Finely grinded iron ore powder of 100 (149 mm) and 200 (74 mm) mesh sizes were passed via shaking table and magnetic separator subsequently. The iron ore was successfully .

Get Price -

Wet High Intensity Magnetic Separators | Multotec

Appliions include heavy minerals, ilmenite, manganese and iron ore (haematite) beneficiation; PGM upgrading as well as manganese recovery from slimes dams. This offers innovative new approaches and technology for solving paramagnetic minerals separation processes that are as efficient as they are costeffective. Magnetic separators that used permanent magnets could generate fields of low ...

Get Price -

Iron Ore benefiion Plants

Hematite Iron Ore Beneficiation Plant: Star Trace offers turnkey solutions for Hematite Iron Ore Beneficiation Plant. We are one of the leading project suppliers for Hematite Iron Ore Beneficiation Plant and we work closely with our customers to fulfill their specific needs for a .

Get Price -

Beneficiation of microfine magnetic minerals from ...

(2018). Beneficiation of microfine magnetic minerals from reductive iron ore with ultrafine grindingmagnetic flocculation separation. Separation Science and Technology: Vol. 53, No. 1, pp. 136145.

Get Price -

mining technology: beneficiation of Low grade iron ore fines

· Lot of low grade Iron ore fines are generated during preparation of lumps, calibrated ores and sinterfines. In addition to these fines, 1015% of ore mined is generated as slimes and are discarded as tailings. These fines and tailings are potential sources to produce pellet grade concentrate after suitable beneficiation. Another source of pellet feed concentrate is from low and off grade ores ...

Get Price -

cost of conversion of iron ore fines into filter cake ...

· The iron ore fines will then be supplied through 253 km slurry pipe line ... Ore Beneficiation – SUPERIOR MINERAL RESOURCES LLC. 7 Feb 2013 . A method of enriching the iron content of low grade iron ore bearing materials . The process includes reducing the low grade iron ore bearing materials to a fine .. of iron that can be cost effectively converted into metallic iron and .

Get Price -

beneficiation of iron ore fines in australia

Beneficiation of Fine Iron Ores using the Desand Process,Description The lowgrade clayrich 10 mm fraction of fine iron ores have often proved difficult to upgrade and capital intensive to process when using traditional wet beneficiation technology including single or two stage hydrocyclone desliming wet high intensity magnetic separation WHIMS spirals and final dewatering using fine screens ...

Get Price -

USA

Beneficiation of magnetic iron ores Download PDF Info Publiion number USA. USA US342194A USA USA US A US A US A US 342194 A US342194 A US 342194A US A US A US A US A US A US A Authority US United States Prior art keywords aggregates mineral dry .

Get Price -

BENEFICIATION STUDIES ON IRON ORES FROM ORISSA

BENEFICIATION STUDIES ON IRON ORES FROM ORISSA 1. Badampahar Iron Ore The sample, 3" to fines in size, consisted of rather soft yellowish lumps. Hematite and hydrated oxides of iron and small amounts of magnetite were the iron minerals present. Veins of psilomelane were observed in some specimens. Quartz, clay and some lateritic material ...

Get Price