-

High performance HAR talcs for plastics

towards increasingly highperformance products, particularly in the realm of weight reduction and zerogap design. Because conventional jet milling technologies, also known as micronization technologies, have reached their full potential for both grinding and delaminating talc, Imerys Talc has developed a range of high aspect ratio talcs to meet

Get Price -

How to disperse and stabilize pigments

Add any other additives, 3. Add the pigment, in stages, and disperse in the normal manner. In case you want to optimize a Polymeric dispersant millbase, 4 stages are involved. The following example explaining using Avecia Solsperse products (referred to as a ladder series).

Get Price -

Talc or Talcum powder | pulp paper mill

· Talc. Talc is wellknown as talcum powder. It is a natural hydrated magnesium silie – H 2 Mg 3 (SiO 3) 4. Talc is a soft, low abrasive, flatlike particle, chemically inert and organophilic material. These are reason why many paper mill use this filler. commercially talcum powder is a wide range of mineral mixtures.

Get Price -

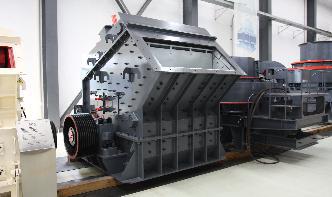

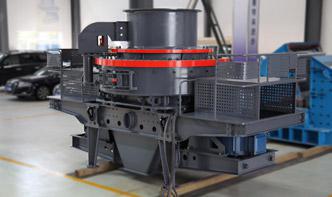

Talc Grinding Mill Talc Powder Making Solutions

Talc powder processing technological process. Phase one: raw material crushing Talc blocks will be crushed to 15mm50mm fineness by crusher. Phase two: grinding Talc material will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding.

Get Price -

Peptizers | Rubber Additives | Products | Dongeun

> Products > Rubber Additives > Peptizers Peptizer During mastiion, while performing compromise liquidation and cutting the molecular chains of the molecular cohesion with mechanical shearing force on the raw rubber, this chemical is used to accelerate the cutting of the molecular chains.

Get Price -

The Complete Book on Rubber Processing and Compounding ...

The Complete Book on Rubber Processing and Compounding Technology Author: NIIR Board of Consultants and Engineers Format: Paperback ISBN: Code: NI174 Pages: 712 Price: Rs. 1, US Published: 2006 Publisher: Asia Pacific Business Press Inc. Usually ships within 5 days Rubber products industry is an important resource based industry sector in India.

Get Price -

CASE STUDIES

We constantly conduct case studies on our additives to continuously improve them and develop new products. At IruChem, we strive to ensure that our products stay at top of the game in terms of performance. Thus, IruChem is always on the lookout for new trends in plastic and rubber industry.

Get Price -

milling amp b processing of talc mineral

talc mill for mineral products additives smart. End products of pulp and paper mills depend on the pulping process Talc Mill For but instead a mineral rich talc mill for iron ore crushing amp amp . .

Get Price -

How to Process Talc (the Softest Mineral)? | Fote Machinery

· Talc in rubber Fillers and antisticking agents for tires, pharmaceutical stoppers, cables, etc. 7 Talc in makeup Baby powder, soap,antiperspirants; cosmetics (blushes, foundations, eye shadows and lipsticks). 8 Talc in medicine Additives to medical lubricants, tablets and .

Get Price -

Antislip Agents for Plastics

· Used in packaging and stackable items... view more. Appliions. Packaging Feeling / touch>Antislip BA FG3435 . Astra Polymers . BA FG3435 by Astra Polymers acts as ... Ultrafine talc. Is a filler masterbatch with ... texturing agent and antislip agent. Exhibits a rubberelastic behavior in molten state because of very high ...

Get Price -

Talc – NLP Minerals India Pvt. Ltd.

Talc has been valued for centuries as a body powder. Today it also plays an important role in many cosmetic products, providing the silkiness in blushes, powder compacts and eye shadows, the transparency of foundations and the sheen of beauty creams. In pharmaceuticals, talc is an ideal excipient, used as a glidant, lubricant and diluent.

Get Price -

Introduction to rubber processing and safety issues

Many rubber compounding additives such as azodicarbonamide, ... Plastics and rubber machines — Tworoll mills — Safety requirements ... but twin or triple screw extruders may be used for comp lex products such as cable sheathing where they may be several layers of compound ...

Get Price -

Manufacture of Rubber Products

The manufacturing of rubber products involves six principal processing steps (mixing, milling, extrusion, calendering, curing, and grinding), with ancillary steps in between. Initially, the raw rubber (natural or synthetic) is mixed with several additives which are chosen based upon the desired properties of the final product.

Get Price -

Talc Processing

11/95 Mineral Products Talc Processing Process Description19 Talc, which is a soft, hydrous magnesium silie ( .H 0), is used in a wide range of 2 2 industries including the manufacture of ceramics, paints, paper, and asphalt roofing.

Get Price -

Talc Powder – Minerals

Talc Powder Dolomite is Carbonate of Calcium and Magnesium "Ca Mg (CO3)2". We are recognized as one of the prominent Dolomite Rock Powder Manufacturers and Suppliers in India.

Get Price -

Rubber Compounding

Rubber Compounding. Rubber compounding involves the science and engineering of rubbers and rubber additives, such as processing aids, fillers, and curing agents, in definite proportions to obtain a uniform mixture that will have desirable physical and chemical properties to meet processing at low cost and end use performance.

Get Price -

Productfriendly compaction and deaeration of finegrained ...

The productfriendly deaeration and compaction of fine, freeflowing bulk solids with Grenzebach's VACUPRESS opens up new possibilities for optimization: With possible volume reductions of up to 75%, and a simultaneous increase in bulk density, the VACUPRESS creates the optimal starting point for your transport and storage processes.

Get Price -

Additives Fillers

Additives Fillers. A wide variety of additives and modifier ingredients can be used to expand the usefulness of polymers, enhance their processability or extend product durability. Although additives are generally used in relatively low quantity by weight compared to resins, reinforcements and fillers, they perform critical functions.

Get Price -

Talcubex Additives for Rubber Plastics

Contact Us. T: 01536 460020 F: 01536 462400 E: info Elm House, Medlicott Close, Oakley Hay, Corby, Northants, NN18 9NF

Get Price