-

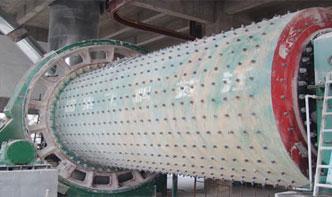

What Is a Ball Mill?

Mar 10, 2020 · Overview of Ball Mills. As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material. It consists of a hollow compartment that rotates along a horizontal or vertical axis. It's called a "ball mill" because it's literally filled with balls. Materials are added to the ball mill, at ...

Get Price -

PULVERIZING BALL FROM KENNEDYVAN SAUN AIR SWEPT TUBE MILL .

The two pulverizers were...KennedyVan Saun ball mills, but were engine driven instead of turbine driven...the coal was supplied from the ready bunkers, through the feeders to the mills by closed systems. The primary air fans were built by the KennedyVan Saun Manufacturing and Engineering Corporation and were driven by Sturtevant turbines.

Get Price -

ball and race mill diagraph

Coil Pulverizers for Boilers. Jun 1,, The fineness of the coal is also important in overall mill efficiency and in, speed mills like ball tube mills, the medium speed mills like bowl, ball and race,, Boiler designers use selection chart which are drawn based on the.

Get Price -

pulveriser mills

Apr 01, 2020 · For Chemical, Pharmaceutical, Food, Cosmetic and other Materials Processing Appliions. MicronMaster® Jet Pulverizers comprise a complete line of advancedtechnology jet energy mills designed to grind any type of crystalline or friable material, producing product in the size range of to 15 microns.

Get Price -

Planetary Milling Equipment | Planetary Ball Mills– MSE ...

Planetary ball mills are much smaller in comparison to common ball mills and are largely used in laboratories to grind sample materials to very small sizes. For this purpose, there are specific types of equipment as can be seen on our website. They are used across several industry fields, including chemicals, ceramics, environmental protection ...

Get Price -

Coil Pulverizers for Boilers

Aug 13, 2009 · Mill air flow variations result in changes in mill outlet temperature and fineness as well as capacity. Ball tube mill. Ball tube mills are either pressurized or suction type. In the pressurized type, the hot primary air is used for drying the coal and to transport the milled coal to the furnace. In this type, leakage in the mill area is high.

Get Price -

Tube And Ball Mill Coal Pulverizer Ppt

Tube And Ball Mill Coal Pulverizer Ppt. Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etc. horizontal tube and ball coal mill erection ppt. Posts Related to horizontal tube and ball coal mill ...

Get Price -

Used Mills Inventory

Pulverizers and mills range in design features for efficient size reduction for a range of products in the chemical, mineral, pharmaceutical and food industries. The different classifiions of Mills are: Ball Mills Pebble Mills – Basically a horizontal tube with balls or stone grinding media, that grinds the material as the tube rotates ...

Get Price -

What is pulverizer and how does it work Zhangjiagang ...

May 19, 2021 · The mills themselves are quite simple, consisting of a horizontallymounted rotating cylinder and liners that protect the cylinder from wear and tear. To work, users place the media inside the cylinder, where it is tossed or tumbled. Tube mills are so similar to ball mills that people sometimes use their names interchangeably.

Get Price -

Grinding Equipments

Ball Mills is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silie, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc. And the ball mill can grind various ores and other materials with dry type and wet type.

Get Price -

Ball and Race Mill

The advantages of ball and race mill are as follows: Lower capital cost. Lower electricity power consumption. Lower workspace required. Lower weight. However, in ball and race mill there is greater wear as compared to other coal pulverizers. The usage of pulverized coal as a fuel has now become the standard method of firing in many huge boilers.

Get Price -

laboratory mill, lab ball mill

MTI has been manufacturing laboratory mill/mixer since 1994, offered the first model of ball mill into the world. Then the following years we've been devoting ourselves to designing the most efficient, practical and affordable laboratory mill/mixer. Thus, many new and fashion models are gradually stepping and finding a place in the ...

Get Price -

Used Pulverizers Mills for sale. Fitzpatrick equipment ...

Reduction Engineering Single Mill Pulverizer, Model 100, 75HP. Used Reduction Engineering Single Mill Pulverizer, Model 100 75HP General Electric Motor, 3555 RPM Eriez Feeder, Model 26C, S/N 5 Deck Sifter, 10HP Blower, Rotary Air Lock 575 Volts/ 3 Phase/ 60HZ 92 Amp...

Get Price -

Ball Mill

Ball mill introduction. The ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silie sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc. Ball mill can grind various ores and materials with dry type or wet type.

Get Price -

mill for coal pulverizers in

Coal Mill Pulverizers Used In Cement Mills. Ball mill for coal pulverizerscoal mill cement plants crusher unit coal mills in cement youtube to achieve the goal of safe efficient and economical coal firing system designs both users and regulatory personnel must have an more coal millcoal bunker in cement industriesball mill is an.

Get Price -

impact mill vs ball mill crusher

Ball mills are large or small tubes used in grinding and mixing materials such as ceramic materials, ores, chemicals and paints etc. Ball mills rotate, partially filled... Read more Impact Mill / Crusher / Breaker Grinding Mills and Pulverizers ...

Get Price -

babcock e type ball mill

Dec 27, 2012 · babcock wilcox horizontal high speed pulverizers – CGM mining .. BABCOCK WILCOX Ball Race Mill, . the type E and EL coal pulverizers made by The Babcock Wilcox . known E and EL type pulverizers use a pair of vertical axis, .. » More detailed.

Get Price -

Mill Speed

Aug 01, 2011 · Dipak K. Sarkar, in Thermal Power Plant, 2015 Lowspeed mill. Mills operating below 75 rpm are known as lowspeed units include ball or tube or drum mills, which normally rotate at about 15–25 types of mills,, ballandrace and rollandrace mills, that generally fall into the mediumspeed egory may also be included in this egory provided their ...

Get Price -

Mills | Fisher Scientific

MM 200, 301 mixer mill, S 100 centrifugal ball mill and PM 400 planetary ball mill (1) MicroMill grinder (1) Mid Size, CrFree, PolyVial Grinding Vial Set (1) Scienceware™ MicroMill™ II Grinder (1) Spex™ SamplePrep™ Freezer/Mill Cryogenic Grinder (1) Two screw top .

Get Price -

Sepor Stainless Steel Batch Ball Mills | Sepor, Inc

The Sepor Batch Ball Mills are constructed of 304 stainless steel (wetted parts), with structural steel frame and support structure. The rugged forged steel trunnions with hubs provide support for the shaft and give structural support for the mill ends. The mill is machined to provide a true alignment of the mill.

Get Price -

Ball Mill Grinding

Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world. Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materials.

Get Price -

What's the Difference Between Ball Mill, Rod Mill and SAG ...

Mar 20, 2020 · Ball mill: Ball mills are the most widely used one. Rod mill: The rod mill has the highest efficiency when the feed size is <30mm and the discharge size is about 3mm with uniform particle size and light overcrushing phenomenon. SAG mill: When the weight of the SAG mill is more than 75%, the output is high and the energy consumption is low ...

Get Price