-

PT Penta Chemicals Indonesia

Raw Mill Cement Grinding Aids . Pentachem. We always CUSTOMIZE our product based on our customer's input materials composition and mill condition. Other Products. Dry Mortar Additive, Concrete Superplasticiser. We are a Specialty Construction Chemical company

Get Price -

(PDF) Cement Manufacturing

cement is made by heating limestone (calcium carbonate) with other materials (such as cla y) to. 1450 °C in a kiln, in a process known as calcinations, whereby a molecule of carbon dioxide is ...

Get Price -

How Cement Is Made

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Get Price -

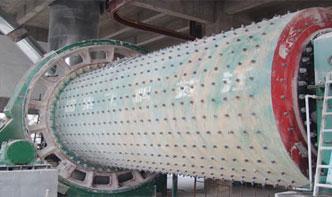

milling in cement industry

Vertical Roller Mill In Cement Industry Wiki. Cement mill . A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Get Price -

Risk Assessment in Cement Manufacturing Process – IJERT

· In cement manufacturing process raising etc. quality of product, the cost should be minimize, improving delivery of product, reducing wastages. Implementation of cement industry day by day to increase the productivity beneficial for our future. New technique be developed to proper control cement manufacturing process.

Get Price -

"BEST AVAILABLE TECHNIQUES" FOR THE CEMENT INDUSTRY

Cement has played a key role as a construction material throughout the history of civilisation. In Europe the use of cement and concrete in large civic works can be traced from antiquity through modern times. Portland cement was patented in 1824 and by the end of the 19th century concrete, based on Portland cement.

Get Price -

Erection Procedure Of Cement Mill

erection procedure of cemant grinding mill. erection of vertical mill in cement industry erection of vertical mill in cement industry. erection of coal mill in cement plant. cement industry the ball mill was really an epochmaking breakthrough as for, appliions of the vertical roller mill for cement grinding are less prevalent, In contrast to equipment cost, the costs for civil ...

Get Price -

Cement Raw Mill Operating Instructions

Raw Materials Area and Cement Mills Area •Performing regular and routine Maintenance tasks according to the maintenance schedule. Mill feed system Chemical characteristics of the materials to be handled Prehomogenisation Prehomogenisation is often necessary in the cement industry, in cases where the raw material chemical composition varies greatly.

Get Price -

Cement Milling Process Pdf

Cement raw milling process Raymond Grinding Mill. cement raw milling process. Biomass burning in cement kilns is a wellestablished technology, which can .

Get Price -

COMMON HAZARDS AND CONTROL MEASURES IN CEMENT PLANT

· Typical Cement Plant Quarrying and Raw Materials Preparation Quarry –Extraction of limestone and other raw materials Crusher –The extracted material .

Get Price -

The essentials of electrical systems in cement plants | EEP

· The desired raw mix of crushed raw material and the additional components required for the type of cement, silica sand and iron ore, is prepared using metering devices. Roller grinding mills and ball mills grind the mixture to a fine powder at the same time as drying it, before it is conveyed to the raw meal silos for further homogenisation.

Get Price -

Milling In Cement Industry

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are effective than ball provide ball mill machine for cement plant, power plant, mining industry, metallurgy industry, etc. Ball ...

Get Price -

raw raw mill in cement plant animations

animation of raw mill in cement plant Raw Mill In Cement Plant,Cement Making Plant. This paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished ...

Get Price -

The Cement Plant Operations Handbook

Cement milling 110 111 The Cement Plant Operations Handbook – Seventh Edition 6. Cement milling Finish milling is the grinding together of clinker with some 35 per cent gypsum, natural or synthetic, for set control, and quite often other components: blastfurnace slag, pozzolan, silica fume, limestone or pulverised fuel ash ('pfa'

Get Price -

Raw Material Milling Cement

Major systems included raw material transport from existing raw material storage bins, raw mill system, kiln feed system, clinker transport, finish milling, cement transport and storage, and dust collection systems. Technical Details. Fuller roller mill sized at 220 TPH with a 1,750hp drive.

Get Price -

Manufacture of Portland Cement Materials and Process

The mixing procedure of the manufacture of cement is done in 2 methods, Dry process; Wet process; a) Dry Process The both calcareous and argillaceous raw materials are firstly crushed in the gyratory crushers to get 25cm size pieces separately.

Get Price -

Cement Manufacturing Process Flow Chart

In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of raw material is limestone.

Get Price -

Thermax cement industry power plant

Power is one of the most important raw materials for the cement industry and accounts for almost 30% of the total cost of cement manufacturing. The power division has a rich experience of working with some of the leading cement manufacturers in India. Cement manufacturers also have the advantage of using the ash generated from the power plant as a raw material for their cement plant.

Get Price -

milling in cement industry

milling in cement industry Farmine Machinery. grinding mill cement industry news from global cement. working principle of ball mill ball cement milling. mar 03, 2015 the ball mill is to grind many kinds of mine and other materials, or to select the mine. it is widely in building material, chemical industry, etc. there are two ways of grinding the .

Get Price