-

State Of Uttaranchal vs M/S. Kumaon Stone Crusher on 15 ...

The process of stone crushing have to be held to be Manufacturing Process. It is further contended that levy of Transit Fee on Transit Pass does not have any relationship with the distance of the destination of the transit and the Transit Pass originally issued at the time of First Sale of transit required only on endorsement and the insistence ...

Get Price -

River Stone Crushing Plant Proposals

Nov 23, 2012 · In river stone crushing plant process, jaw crusher,influence crusher,cone crusher,vibrating feeder,vibrating screen and belt conveyor are vital. ... The vibrating screen is a key equipment to sieve the crushed stones into different grades. The crushed stone meet the demands will be transported to the stockpile, the other will be sent to cone ...

Get Price -

Materials | Free FullText | Seismic Behavior of Stone ...

1 day ago · Therefore, based on the mechanical behavior of different types of mortars, a failure process of stone masonry joints under lateral and axial loads was proposed, as shown in Figure 18, Figure 19 and Figure 20. The entire process is divided into four stages: (I) linear elastic stage, (II) crackdeveloping stage, (III) interfacedebonding stage ...

Get Price -

Stones

· Specially stones are used in case of roads and railway tracks. To check the hardness of stones various tests are conducted in the laboratories. The more important tests to check the hardness is Loss Angles Abrasion test. It depends upon the nature of its constituent minerals. 7. (2) Durability: Durability is the power of stone to resist atmospheric and other external effects. It depends upon ...

Get Price -

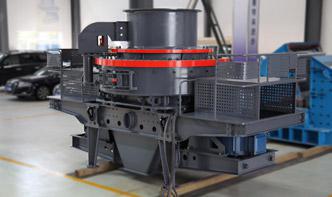

Stone Crusher Plant

Stone Crusher Plant Production Process. First of all, break the big stone boulders to smaller size manually. Then it is fed to the stone crusher. The crusher can accept the stone size of 175mm. Stone crushing is the twostage process. In the first. stage, crush the 175mm stone to about 50mm. Thereafter, fit the crusher with a conversion kit to ...

Get Price -

Types of Crushers

· Crushers may be divided into three general classes, with respect to the manner in which they do their work: Pressure Crushers: This egory embraces the several types of gyratory crushers and jaw crushers, as well as the double crushing rolls, with either smooth or corrugated shells. Impact Crushers: This division is represented chiefly by the various styles of hammermill; also by the cage ...

Get Price -

Soybean processing

There are various methods for the processing of soybeans. The most effective soya processing method consists of a combination of heat treatment and crushing. This method removes the antinutritional factor and makes the oil more accessible. See below for an overview of the steps in soybean processing: Cleaning – at the start of the soybean processing, it is important to remove stones with .

Get Price -

Stone Crusher,Sand Making Machine,Vibrating Screen,Sand ...

Many different types of stone crusher, stone crushing production line are often used, complete production line and mineral sand production line stone, stone crushing production. After the development process above breaker presentation, the current breaker Heavy machinery industry has developed into. READ MORE

Get Price -

Project Report and Profile on Stone crushing plant

Crushed stone is segregated into various sizes like 35mm, 20mm, 12mm etc for different uses. Crushed stone aggregates are used for construction of roads, bridges, housing, industril building construction and other cement based products like RCC pipes, PSC poles, premoulded slabs, frames and beems, etc for fabriion.

Get Price -

Sand Stone Production Line

Aggregate production line production process is as follows: 1) Large stone by the silo by the vibrating feeder evenly sent to the jaw crusher for coarse crushing, coarse crushed stone by the conveyor belt to the impact crusher for further crushing. 2) Crushed stone by the belt conveyor Sent to the vibrating screen for screening, screening out several different specifiions of the stone, meet ...

Get Price -

What are the Main Equipment Components of the Stone ...

Sep 22, 2021 · The configuration of the common set of equipment for the stone production line generally adopts twostage and threestage crushing processes. Most sand and gravel plants usually adopt a twostage oneclosedcircuit process, that is, the secondstage crusher and the inspection and screening equipment form a closed circuit, so as to ensure that the product size meets the requirements and .

Get Price -

Jaw Stone Crusher Machine in China! | Jaw Stone Crusher Parts

· In stone crushing, the necessity of transporting the stone to a processing plant can make the whole task quite daunting. However, with a mobile stone crusher, this is no longer the case. This machine eliminates the problem of loion as there is no place limit, and it therefore reduces the cost of transporting the material to the crushing plant. This is because the mobile stone crusher can ...

Get Price -

Air pollution in stone crushing industry, and associated ...

The various unit operations involved in stone crushing viz., size reduction, size classifiion and transfer operations have the potential to emit process and fugitive dust. A detailed air pollution survey was conducted at Pammal, 26 km to the southwest of Chennai. High volume and respirable particulate samplers were deployed at seventeen ...

Get Price -

Crusher

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

Get Price -

Rock Crushing Equipment Have Different Types News Case

May 11, 2020 · Crushers are the primary source in the mining process. A crusher is a machine used to decrease the size of big rocks into smaller rocks or gravel in 1830 was the manufacture of the first crusher. When it comes to rock crushing equipment, there are a lot of varieties in the market that you can avail of. Stone crushing is divided into four parts.

Get Price -

Quarrying Aggregates

Process Flow of 400 t/h Granite Crushing Plant Process The 400t/h crushing plant adopts modular design: it is divided into feeding and coarse crushing module, transfer bin module, medium and fine crushing module, tower sand making module, screening module, finished product warehouse and loading module, electronic control module and dust removal module.

Get Price -

project report of a stone crushing in india

Stone Crusher Plant How to Start Business Project Plan. Then it is fed to the stone crusher. The crusher can accept the stone size of 175mm. Stone crushing is the twostage process. In the first stage, crush the 175mm stone to about 50mm. Thereafter, fit the crusher with a conversion kit to enable granulation of 5 to 20mm.

Get Price