-

Iron Ore Pelletizing Process: An Overview

Bentonite is an effective, widely used binder in the iron ore pelletizing process. Its low price is an important factor for its extensive use. However, bentonite incorporates silica and alumina, which are undesirable contaminants to pellets. Additionally, it is a natural material with variable composition depending on its origin.

Get Price -

USA

A process of removing iron impurities from ores, particularly useful for removing stains of iron impurities adhered to silica sand particles, comprises grinding the ore, washing and desliming the ground ore to remove the major part of the claytype binder, attritionscrubbing the deslimed particles to release further amounts of binder therefrom, washing and desliming to remove said binder ...

Get Price -

Iron And Steel Production

diagram of the iron and steel industry in Figure Coke production is discussed in detail in Section of this publiion, and more information on the handling and transport of materials is found in Chapter 13. Sinter Production The sintering process converts finesized raw materials, including iron ore, coke breeze,

Get Price -

machinery and equipment used in the extraction of iron ore ...

· Iron Extraction – Crusher Plant Machine And Mining Equipment .. Iron is mined almost exclusively in surface operations. The most predominant surface mining methods used to extract iron ore are openpit and opencut methods. » More detailed.

Get Price -

used ore refining equipment

Smelting Refining Melting Equipment 911 Metallurgist. Smelting Furnace of Iron Ore Laboratoryscale experiments showed that pig irons and steels of acceptable grade can be made by arcfurnace methods from east Texas siliceous ores containing less than 25 percent iron.

Get Price -

Precious Metal Refining Process | The Perth Mint

Gold Refining. Gold mines process ore using various techniques to produce an alloy composed primarily of gold and silver, which is called a dore bar. The composition of dore can vary significantly between mines, but generally the gold dore bars the Perth Mint processes are composed of between 7080% gold and 1015% silver.

Get Price -

Gold Refining Methods

· The use of a blast of air on the surface of molten gold or silver is probably the oldest of the refining processes. The method appears to be described in the Book of Ezekiel, to which the date 593 is assigned, and the principle is the same as in cupellation, which was .

Get Price -

Nickel: smelting, producingMetalpedia

Nickel is recovered through extractive metallurgy: it is extracted from its ores by conventional roasting and reduction processes that yield a metal of greater than 75% purity. In many stainless steel appliions, 75% pure nickel can be used without further purifiion, depending on .

Get Price -

Titanium Extraction and Refining | Titanium Processing Center

· Titanium processing is done with something called the Kroll Process which, even when it was first introduced in the 1930s, has never been the most efficient way to go. However, in all that time, no one has been able to develop anything any better. First, titanium oxide ore is combined with chlorine to make titanium chloride.

Get Price -

Genera Processing Technology For Minerals | Prominer ...

Flotation is a typical mineral ore processing method based on the difference of the physical and chemical property and floatability between valuable minerals and veins. Technically, flotation can be used in almost all of the mineral separation. It is especially efficient to process metal and nonmetal minerals like copper, pyrite, iron, gold ...

Get Price -

Steel production: from iron ore to functional industrial ...

· First, the raw materials, either iron ore or scrap iron (depending on the process), are converted into molten steel. The orebased process uses a blast furnace or smelter and the scrapbased process uses an electric arc furnace. Next, the molten steel is poured and solidified in a continuous caster. This produces what we have mentioned before ...

Get Price -

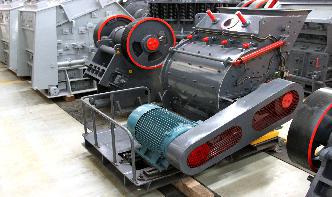

equipment used in refinery process of iron ore

equipment used in the refinery process of iron ore . equipment used in the refinery process of iron ore. ... The puddling furnace is a metalmaking technology used to create wrought iron or steel ... Equipment News ... silver ore refining plants and machinery Silver Ore Refining Plants And Machinery, process ... plant and mining equipment. .

Get Price -

Sintering Process Equipment Used in Iron and Steel ...

Sintering Process Equipment Used in Iron and Steel Manufacturing. ... Sinter is created by mixing iron ore concentrate with several additives such as limestone and silica to control the chemistry and then igniting it at 1200°C in a continuous beltfed furnace.

Get Price -

Iron Ore

· Iron Ore: Mineralogy, Processing and Environmental Issues summarizes recent, key research on the characterization of iron ores, including important topics such as beneficiation (separation and refining), agglomeration (, production of pellets or powders), blast furnace technology for smelting, and environmental issues relating to its production.

Get Price -

The Latest Developments in Iron Ore Processing

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones – diameter –Operating capacity of 600800t/h –Efficient separation at SG's as high as /cm3 Dense Media Separation on Iron Ore •

Get Price -

The Gold Smelting Process

· *Iron removal . Iron in the gold ore can be oxidized with the Nitre and this can corrode your smelting pot increasing the smelting cost and in other cases may cause leaks which can be astrophic and result in huge losses. The iron in the gold ore can be removed by the oxidation of the iron by use of either a forced air oven or nitric acid.

Get Price -

Mineral processing and refining | ABB

Optimized and integrated mineral processing. To produce the required commodity such as ore concentrates, pellets and DRI/HBI for iron ore, copper hodes, nickel or zinc ingots as well as alumina, etc, ABB processes not only cover material handling or comminution (crushing and grinding) but also hydrometallurgy (ore beneficiation / concentration and/or SXEW), agglomeration (including ...

Get Price -

Chapter 82

The metal smelting and refining industry processes metal ores and scrap metal to obtain pure metals. The metal working industries process metals in order to manufacture machine components, machinery, instruments and tools which are needed by other industries .

Get Price -

Refining | Article about refining by The Free Dictionary

are used in the refining of iron; the amalgamation process amalgamation process, in particular, a method to extract gold and silver from ores. The ore is crushed and treated with mercury, in which the metal dissolves. The amalgam is heated and the mercury evaporates, leaving pure gold or silver..... Click the link for more information. and the ...

Get Price -

Notes OCCURRENCE AND EXTRACTION OF METALS

Iron Iron ore reserves in the country are estimated at 1750 crore ... The process of extracting the metals from their ores and refining them is called metallurgy . ... In this process, finely powdered ore is mixed with either pine oil or eucalyptus oil. It is then mixed with water.

Get Price