-

Sulfide Ore Grinding Copper

Sulfide Ore Grinding Copper. Determination of liberation size of Akiri copper ore the amount of water required to process copper sulfide ore through a conventional crush grind flotation concentrate circuit ranges from roughly 1 5 metric tons Commonly copper is treated Turkey Copper Ore Crushing Line Mining Crushing Grinding Turkey Copper Ore Crushing Line The client is a

Get Price -

Copper Processing, Processing Copper Ore, Copper Flotation ...

The ore properties of the ore dressing plant that to be selected determines the ore dressing process, for example, the nature of the copper ore directly determines the subsequent equipment and copper ore dressing technology. There are many mineral processing methods, what determines the specific method is ore types.

Get Price -

4 Things to Make Your Copper Ore Processing Successful ...

Oct 28, 2021 · The oredressing method of processing simple copper sulfide and mixed ore usually chooses the flotation beneficiation. While the way of polymetallic copper sulfide ore processing, according to its different composition, needs to be selected from the methods such as flotationgravity separation, flotationmagnetic separation, and flotation ...

Get Price -

Recover

Dithiophosphate Aqueos (MC208) Has excellent selective properties for copper ore flotation and an excellent collector for gold, silver and copper. Collector Blend (MC347E) Partially water soluble and widely used in copper sulphide ore flotation, particularly when a secondary mineralization of molybdenum or silver exists.

Get Price -

Mine provides mining, gold, copper, coal ...

The above flowsheet shows a basic copper mine process, from mine to metal. There are two distinct types of copper ore, the sulfide ore and the oxide ore. The sulfide ores are beneficiated in flotation cells, while the oxide ores are generally leached. First the copper ore from a open pit mine is blasted, loaded and transported to the primary crushers. Then the ore is crushed and screened, with ...

Get Price -

Laboratory Testing for Sulfide Flotation Process Development

A carefully planned laboratory test program is the foundation for the successful development of a sulfide flotation process. In this paper, the development of a coppermolybdenum flotation process is described. However, the concepts discussed can be applied to most sulfide flotation systems and to many industrial minerals projects as well.

Get Price -

Copper Mining and Processing: Resources and Glossary ...

In copper processing, is typically used with copper sulfide ores, and involves froth flotation, thickening, smelting, and electrolysis. reclamation: In mining, the process of restoring land that has been mined to a more natural or economically usable state.

Get Price -

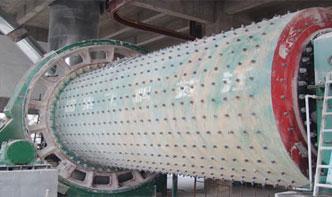

Copper ore process line

Almost all copper sulfide ores have sulfides containing iron, so in a sense, the flotation of copper sulfide minerals is essentially the separation of copper sulfide and iron sulfide. Whole set of copper ore processing equipment

Get Price -

EFFECT OF SEAWATER MAIN COMPONENTS ON FROTHABILITY IN .

Effect of seawater main components on frothability in the flotation of CuMo sulfide ore 19 Frothing agents are employed in flotation to facilitate air dispersion into fine bubbles and to stabilize the froth. Froth stability depends on the frother type and concentration, but also is a function of other variables, such as particle size,

Get Price -

The Magic Effect of Lime in Mineral Processing

Feb 20, 2021 · When flotation of various nonferrous metal sulfide minerals with yellow drug type trapping agent (such as flotation of copper, lead, zinc, and other sulfide minerals from the ore), as the ore usually contains a certain amount of iron sulfide minerals, such as pyrite, albite, magnetic pyrite or sulfur arsenopyrite, etc., with lime suppression ...

Get Price -

Copper Flotation

Remember that only % of the ore is copper. The copper minerals and waste rock are separated at the mill using froth flotation. The copper ore slurry from the grinding mills is mixed with milk of lime (simply water and groundup limestone) to give a basic pH, pine oil (yes, it comes from trees a byproduct of paper mills) to make bubbles ...

Get Price -

Crushing Process Of Sulfide Ore

Chalcopyrite basic operations flotation process, brass ore broken through crush ... crushing process of sulfide ore Overview. ... There are two distinct types of copper ore, the sulfide ore and the oxide ore. ... Copper ore processing equipment, copper ore crushing grinding process, ...

Get Price -

Managing Process Water Quality in Base Metal Sulfide Flotation

Managing Process Water Quality in Base Metal Sulfide Flotation. While water represents a major proportion of the mineral pulp processed in flotation circuits, relatively little research effort has been committed to understanding and controlling the influence of water quality on this process. Historically, this probably stems from the perception ...

Get Price -

Mine provides mining, gold, copper, coal ...

The above flowsheet shows a basic copper mine process, from mine to metal. There are two distinct types of copper ore, the sulfide ore and the oxide ore. The sulfide ores are beneficiated in flotation cells, while the oxide ores are generally leached. First the copper ore from a open pit mine is blasted, loaded and transported to the primary ...

Get Price -

Study on Appliion of Intensifying Depression Talcum in ...

Talcum is a common gangue with which sulphide ores are associated, it has an adverse impact on sulphide ores flotation and product index due to its high natural floatability. In this paper it takes talcumbearing copper sulphide ores from DongChuan in Yunnan province as experimental samples, and a series of tests on depressing talcum in the copper suphide ore flotation were carried out.

Get Price -

Copper sulfide flotation processing

Nov 02, 2021 · Generally, copper sulfide ore mainly includes single copper sulfide ore and polymetallic copper sulfide ore. The flotation process of the former is generally simple, and the flotation process of the latter is more complied. 1. Single copper sulfide flotation The mineral composition of a single copper sulfide ore is simple. The copper minerals mainly [.]

Get Price -

Process mineralogy as a key factor affecting the flotation ...

· The aim of this study is to apply process mineralogy as a practical tool for further understanding and predicting the flotation kinetics of the copper sulfide minerals. The minerals' composition and association, grain distribution, and liberation within the ore samples were analyzed in the feed, concentrate, and the tailings of the flotation processes with two pulp densities of 25wt% .

Get Price -

separation by flotation of copper lead zinc sulphides

The froth flotation technology of copper, lead and zinc sulfide ore is very rich. A certain copper, lead, zinc and sulfur ore in Tibet is used for partial mixed flotation process. It is mixed with medium ore for regrinding, and activated carbon is used as the agent for separation.

Get Price -

copper mining and processing

The above flowsheet shows a basic copper mine process, from mine to metal. There are two distinct types of copper ore, the sulfide ore and the oxide ore. The sulfide ores are beneficiated in flotation cells, while the oxide ores are generally leached. First the copper ore from a open pit mine is blasted, loaded and transported to the primary ...

Get Price -

Enhanced sulfidation xanthate flotation of malachite using ...

May 18, 2017 · In nature, copper mainly exists in the form of sulfide ore and oxidized ore 5, and this form is an important part of copper resources. Malachite is a typical representation of copper oxide ore ...

Get Price -

Beneficiation of flotation tailing from Polish copper ...

Dec 31, 1995 · Conference: Beneficiation of flotation tailing from Polish copper sulfide ores Title: Beneficiation of flotation tailing from Polish copper sulfide ores Full Record

Get Price -

Development of Copper/Nickel Separation at INCO

· Improved copper / nickel separation in milling operations has the potential to substantially improve the processing of the resulting concentrates and thus the overall return from the extraction of nickel and copper from sulfide metal by itself or in alloys with other metals and materials makes a significant contribution to modern society. The relatively high price that ...

Get Price