-

CHAPTER 11 SIZE REDUCTION

SIZE REDUCTION Raw materials often occur in sizes that are too large to be used and, therefore, they must be reduced in size. This size reduction operation can be divided into two major egories depending on whether the material is a solid or a liquid. If it is solid, the operations are called

Get Price -

Coal washing | Coal preparation | Coal washing plant pcocess

· Our coal washing plants including a raw coal preparation modular, a coal feed and washing module and a dewatering module. we also provides high quality equipments for coal washing plants such as vibrating screens, vibrating feeders, fine coal slurry separators, magnetic separators, cyclones, coal filter press and heavy media containers.

Get Price -

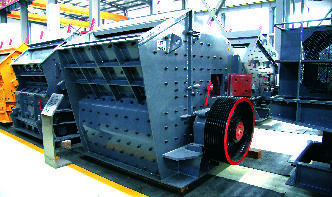

impactors reduction machine

Size Reduction Impactors Thomasnet. Manufacturer of size reduction impactors. Designed for size reduction of minerals, ores chemicals. Available to process up to 2 in. feed for particle size reduction to 68 mesh. Features includes raw feed sizes up to 2 in. .

Get Price -

(PDF) METHODS OF SIZE REDUCTION AND FACTORS AFFECTING SIZE ...

Size reduction process is also termed as Comminution or Diminution or Pulverizations. There are many types of sizereduction equipment, ... Factors related to natu re of raw m aterials affecting ...

Get Price -

Cost Reduction in Mining Operations – Discussion – Mining ...

· Cost Reduction in Mining Operations Discussion The operating cost structures of mining operations globally have increased significantly over past years. When raw material prices are high it might appear to be an odd time to be thinking about cost reduction, but in fact it is the ideal time. History has shown us is that.

Get Price -

coal size reduction grinding

Crushing of coal and calculation of size reduction efficiency. Feb 25, 2015 · Crushing of coal and calculation of size reduction efficiency. grove grindability index HGI is defined to classify coals on the basis of their easy while grinding It is obtained by grinding 50 g of 1mmx mm of dried coal sample in a standardised balland race mill for 60 cycles at a seed of 20

Get Price -

IS 3595 (2002): Code of Practice for Fire Safety of ...

burning equipment. Wide variations in the size of raw coal may also result in errartic or uncontrollable coal feeding with its attendant hazards. Coal stored in bulk is susceptible to spontaneous combustion. Adequate precautions must, therefore, be taken during its storage as outlined in to Care must also be taken to ensure that ...

Get Price -

MINING EQUIPMENT: manufacturers and suppliers ...

· Mining Equipment Manufacturers: Construction and mining equipment cover a variety of machinery such as hydraulic excavators, wheel loaders, backhoe loaders, bulldozers, dump trucks, tippers, graders, pavers, asphalt drum / wet mix plants, breakers, vibratory compactors, cranes, forklifts, dozers, offhighway dumpers (20T to 170T), drills, scrapers, motor graders, rope shovels etc.

Get Price -

Particle Size Reduction Equipment

Generally used for reducing material to a particle size as low as 180m (80 mesh) they produce less dust and heat than alternative forms of milling. View Details Send Enquiry Attritors Particle Size Reduction Equipment. Attritors are the most efficient particle size reduction equipment.

Get Price -

Charcoal Coal Briquette Machine | Briquettes Extruder ...

The charcoal briquettes extruder machine is widely used for the molding of charcoal powder, coal , coal gangue, lignite, anthracite, iron powder, aluminum powder, and other raw materials. And it is often used with the wheel grinder mixer and briquettes cutting machine, and it is the common equipment in charcoal briquettes production line.

Get Price -

Investigation of the energysize reduction and mineral ...

· ABSTRACTRaw coal was ground in a Hardgrove mill, and mineral liberation from coal was investigated by floatsink test and electron probe microanalyzer (EPMA). Based on EPMA, associated conditions of mineral were determined. Analyses of energysize reduction show that energy efficiency decreases with time. For + mm progenies, yields of particles in − −3 decrease with the ...

Get Price -

Heavy Media Separation Process

· The heavymedia separation process, or HMS, employing ferrous media, usually ferrosilicon and/or magnetite, is the most generally used process for sinkfloat separations. A stable medium over the range of specific gravities from to can be maintained within close limits and is cleaned and recovered by magnetic means.

Get Price -

5 types of coal briquette machine. Review the briquetting ...

Coal briquette is easy to get by using coal briquette machine. But before we use our coal fine to make the briquette, still there's something we need to pay attention to. Size of coal fines. Not all of the coal dust we use is with very small size, we need to ensure our raw material with the proper size, like under 5mm or under 3mm are both ...

Get Price -

Coal Mining and Production

Raw coal may be sold as mined or may be processed in a beneficiation/washing plant to remove noncombustible materials (up to 45% reduction in ash content) and inorganic sulfur (up to 25% reduction). Coal beneficiation is based on wet physical processes such as gravity separation and flotation. Beneficiation produces two waste streams: fine materials that are discharged as a slurry to a ...

Get Price -

equipment used of different ranges in coal washery

selection of size reduction equipment especially for coal ... Osborn inch jaw crusher double roller crusher and Retsch ZM200 ultra centrifugal mill were some of the equipment used to reduce the coal samples from a top size of 150 mm to a suitable size distribution range of 150–212 μm.

Get Price -

Coal Port Operation Maintenance | Bangun Arta

Material handling for raw coal from stockpile to Jetty / Port Dock with size reduction process in crushing plant with various size or size (50 mm, 100 mm, 150 mm, 200 mm) then loaded with barge loading conveyor into Barge / barge;

Get Price -

Energysize reduction of coals in the Hardgrove machine

To simulate the grinding process in an industrial vertical spindle mill, the Hardgrove mill was fitted with a powermeasuring meter to investigate the breakage characterizations of different narrow size fractions of coal. Power consumption in the grinding process was precisely recorded at the sampling frequency of 1 second with the help of sampling software for power.

Get Price -

New Technologies for the Steel Industry

Two New Coal Direct Reduction ... Size range raw steel 17 integrated33 specialty 43 scrap/DRl Total number of ... ondary steelrefining equipment such as vacuum degassing units, electroslag remelting equipment, argonoxygen decarburization (AOD) units, in addition to special forming

Get Price -

Direct and smelting reduction

Direct and smelting reduction. Enable the use of lowergrade ores while minimizing lifetime operating costs and emissions with our direct smelting technologies. Outotec Direct Reduction technologies are based on 50 years of experience in delivering solutions for customers in the ferrous direct reduction sector, encompassing the full range ...

Get Price -

Eriez

Equipment for the Coal Industry. Eriez is truly a one–stop resource with our wide range of products to assist in the processing of coal. No other source designs, manufactures and locally supports such an assortment of equipment to convey, clean and analyze coal.

Get Price -

size reduction equipment raw coal cs cone crushers

size reduction equipment raw coal cs cone crushers Size Reduction Visual Encyclopedia of Chemical Engineering Size Reduction Raw materials undergo size reduction through different mechanisms: impact, compression, and attrition. ... or fibrous materials that fracture on compression, such as in the production of sponge metal, asbestos, bituminous coal and certain plastics.

Get Price -

Particle Size Reduction Equipment | Williams Patent Crusher

Pulverizers reduce the size of coarser materials like coal, limestone, phosphate rock, pigments, tobacco, clay, and barite. With our customization options, a Williams pulverizer can be the allinone size reduction equipment you need for your appliion. Read more about the specifics of our pulverizers, such as our roller mill pulverizer machine.

Get Price -

4 Coal Mining and Processing | Coal: Research and ...

· Although the United States has the vast coal resource described in the previous chapter, perhaps as much as 4 trillion tons, the key issue for policy makers is the amount of coal that is economically is not a fixed quantity, but depends on the geological resource, the market price, and the cost of mining. The particular characteristics of the coal mining industry create unique ...

Get Price -

MMD SIZERS

processing equipment for the UK underground coal mining industry, MMD developed the Twin Shaft MINERAL SIZER™, an innovative product providing a technological breakthrough in mineral reduction. MMD has also successfully designed and manufactured mobile, semimobile and static Sizer stations for the complete mineral sizing solution.

Get Price -

Coal Preparation Plant | Coal Preparation Process | Coal ...

Crushing Screening: Raw coal is transported to crushing workshop by belt conveyor. First, it is pre screened by a circular vibrating screen with a sieve opening of 50 mm. +50mm materials and extra large gangue enter the crusher and are crushed to – 50mm, and then transported to the coal washing workshop together with 50mm raw coal that under the vibrating screen.

Get Price