-

Jaw Crusher | Metrotrak | Powerscreen

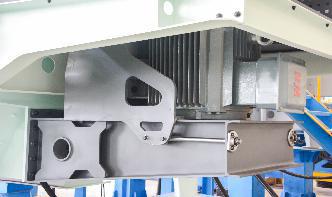

Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won't have to be blasted down to a fine size. Powerscreen jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear parts.

Get Price -

Jaw Plates | Jaw Crusher Parts | HANDY

Jaw plate, also called toothed plate is the key wearresistant part of jaw crusher. A set of jaw plates generally consists of a movable plate and a fixed plate. They work together to crush materials. The crusher parts come in various profiles and sizes for different jaw crushers. They are mainly made of high manganese steel.

Get Price -

Zhili New Materials

We provide spare parts for hammer crusher,jaw crusher,cone crusher,impact crusher and vertical the industry's leading production base for wearresistant materials, our company is dedied to new materials for mining, cement plant, Power plant, scrap recycling industry to provide services.

Get Price -

Export Data and Price of jaw plate jaw crusher under HS ...

Value (INR) Per Unit (INR) Oct 18 2016. . CRUSHER BOX SIZE 700X400 AS PER MIL DRAWING FITTED WITH MN GR III JAW PLATES WITH Ireland. Nhava Sheva Sea. NOS.

Get Price -

Jaw Crusher Wear Parts Manufacturers Suppliers

Jaw Crusher Wear Parts Manufacturers, Factory, Suppliers From China, We are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to .

Get Price -

China PE750X1060 Jaw Crusher Parts, Jaw Plates ...

China PE750X1060 Jaw Crusher Parts, Jaw Plates, Side Plates, Find details about China Crusher Parts, Jaw Liner from PE750X1060 Jaw Crusher Parts, Jaw Plates, Side Plates JINHUA STEEL CASTING AND ENGINEERING PARTS CO., LTD.

Get Price -

Jaw Crusher | Premiertrak 600 | Powerscreen

Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won't have to be blasted down to a fine size. Powerscreen jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear parts.

Get Price -

Choosing the correct jaw profile for your crusher

· Jaw plates what to do? When the wearing of the jaw plates is severe, it is a known fact that crusher performance is not ideal, because the empty spaces between the teeth are reduced, encagement happens frequently, the crushing angle is changed or, in .

Get Price -

Jaw crusheride plate cheek plate with low price and ...

· Cheek Plates. Jaw Crusher Parts. The cheek plates lining the inside of the jaw crusher cavity are subject to both high stress (during the crushing cycle) and low stress (between crushing cycles) abrasion. This abrasion wears away the material from which the cheek plates are made. Clifton Steel's Tensalloy™ Blue material is a [.]

Get Price -

Study on Liner wear in Single Toggle Jaw Crushers: A Review

The profiles of crushing plates of a jaw crusher and the comminution processes are closely related. This is because, the jaw liners interact directly with the crushed material during the crushing process. That notwithstanding, problems surrounding crushing plate design about wear .

Get Price -

Exchanging jaw crusher wear plate

Exchanging jaw crusher wear plates steps: Position the hook of a mobile crane vertically above the wear plate (31000). Be aware of the weight of the wear plate. Make sure the moving jaw is reclined so that the wear plate will not fall forwards while releasing the upper end. Never stand in the crushing chamber while releasing the upper end with ...

Get Price -

Crusher wear and spare parts | Bowl Liner | Jaw Plate

GUBT is a growing company with over 30 years of experience in production and supplying crusher wear and spare parts for the aggregate, cement, mining, and recycling indust ... Concave, Mantle, Jaw plate, Cheek Plate, Blow Bar, Impact Plate, Rotor TIp, Cavity Plate, Feed Eye Ring, Feed Tube, Feed plate, Top upper lower wear plate, Rotor ...

Get Price -

Welcome To Crusher Wear Parts

Welcome to crusher wear parts, the Leader in solutions for the aggregate and mining industry. We understand the demands of this industry, and the toll it takes on the equipment needed to run it. Our goal is to provide you with the best parts and equipment so that you can get the job done! We sell OEM replacement parts for major brands of ...

Get Price -

Jaw crusher parts

Jaw crusher wear parts are designed for processing all rock types in surface and underground operations. Our offering consists of jaw plates such as different onepiece jaws and twopiece jaws as well as cheek plates. Due to the wide range of appliions and feed materials, ...

Get Price -

Crusher Liners | Cone Crusher Liners | Crushing Wear Parts

description Crusher Liners CSP has been supplying CSP Crusher wear liners for over 30 years to global steel, mining and mineral processing, aggregate, oil sands, cement, and power customers. Our CSP Crusher wear liners offering covers major gyratory crushers, jaw crushers, cone crushers, impact crushers and roll crushers – optimized for any size reduction need.

Get Price -

Crusher Wear Parts Jaw Plates High Mananese Steel Castings ...

Jaw Crusher Plate > Crusher Parts > Products > . We know that the jaw crusher spare parts maily include the fixed jaw plate and the movable jaw plate.'s Jaw crusher plates are manufactured with super high manganese steel, therefore they have a service life 50~ longer than those made of traditional high manganese steel.

Get Price -

Jaw Crusher Wear Plates

Jaw Crusher Wear Plates. The right jaw design can make a big difference for your jaw crusher. Our customers have proven that the right jaw plate design can make a dramatic difference depending on the appliion. We have many case histories in which wear life increases of 50 are common and some in which wear.

Get Price -

Sandrock Mining

Sandrock Mining produces and supplies crusher wear parts such as the Bowl Liner, Mantle, Jaw Plate, Cheek Plate, Hammer, Bushing, Shafts, Gears etc.

Get Price -

Concaves Mantles,Jaw Plates,Crusher Wear Parts For Sale ...

Jaw Plates. WHITE LAI replacement crusher jaws are engineered to last longer and crush more efficiently, while reducing wear and tear on the crusher. The crusher jaws produce better quality rock more consistently than standard original equipment jaws, while reducing the need for rescreening and recrushing.

Get Price