-

component of machine tools grinding with functions

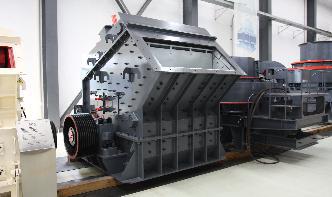

Grinding Machines . Grinding machines, like broaching machines, operate over a range of speeds depending on the type of machine being range from approximately 1250 to 2000m min −1, although in highspeed grinding speeds of up to 5400m/min are achievable (Schey, 1987).The two most common grinding appliions are cylindrical grinding and surface grinding.

Get Price -

Types of Cylindrical grinding machine with Diagram Explained

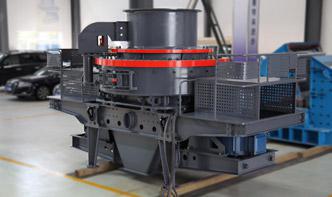

Types of Cylindrical grinding machine with Diagram Explained. This machine is used to produce external cylindrical surface. The surfaces may be straight, tapered, steps or profiled. Broadly there are three different types of cylindrical grinding machine as follows: 1. Plain centre type cylindrical grinder. 2. Universal cylindrical surface grinder.

Get Price -

What is Cylindrical Grinding

In cylindrical grinding operation, the work is mounted between two centres and is rotated. A grinding wheel is mounted on a spindle and revolves at much higher than the work. The work centres are mounted on a table which can traverse at various feeds so that the entire length of the work passes to and fro in front of the wheel.

Get Price -

Industrial robots

functions can be changed without physical alteration; ... Cylindrical robot: a robot whose axes form a cylindrical coordinate system . 1 Introduction 27 Figure : Classifiion of industrial robots by mechanical structure . 28 1 Introduction Examples of articulated robots

Get Price -

Automation Solutions

For all these questions and more, UNITED GRINDING Automation Solutions has the answers. Based at our North American headquarters in Miamisburg, Ohio, our automation experts design, build and manufacture industryleading standard and custom automated systems. We test, integrate and perform runoff on our stateoftheart production floor so there ...

Get Price -

Grinding | Werkzeugmaschinen – Gebrauchtmaschinen

Machine type cylindrical grinder Year of manufacture 1989 grinding depth 75 mm, workpiece diamter 80 mm, sanding table stroke max. 225 mm, table speed 1 8 mph, workpiece headstock, primary reduction for external grinding spindle, spindle motor 0,3 kW, external spindle, internal grinding spindle SFJ JS80 ( rpm),removing device

Get Price -

USER MANUAL

Proper function of the equipment can be ensured only if maintenance is performed according to the instructions given in this manual. The descriptions in this manual refer to the robot and equipment according to the specifiion sheet. These specifiions are subject to change without notice.

Get Price -

JUMAT

Internal cylindrical grinding. Internal cylindrical grinding enables precise grinding of inside functional surfaces, such as drilled holes, cones or flat surfaces. Highspeed grinding spindles are used to achieve the desired cutting speed, despite the smaller grinding wheel diameter.

Get Price -

Chapter 3 Robot Mechanisms

Robot mechanisms analogous to coordinate systems One of the fundamental functional requirements for a robotic system is to loe its endeffecter, a hand, a leg, or any other part of the body performing a task, in threedimensional space. If the kinematic structure of such a robot mechanism is analogous to a coordinate system,

Get Price -

Types of Grinding Machine

· Tool and cutter grinding machine: These are the special types of grinding machines which are used for the machining of cutting tools which are used for milling, turning and drilling operations. The grinding of a tool has two parts manufacturing of new tool and resharpening of an old tool. The simple single point cutting tool which is used in turning is machined or sharpened by using ...

Get Price -

1. Grinding Grinding and Abrasive Machines

Types of grinders Cylindrical grinders This machine is used primarily for grinding cylindrical surfaces, although tapered and simple format surfaces may also be ground. They may be further classified according to the method of supporting the work .Diagrams illustrating the essential

Get Price -

Industrial Robot Technology

· The SCARA robot is more selective in its function and is ideal for manufacturers looking for an industrial robot with arms that can manipulate work with a great deal of precision. The robot can work in a cylindrical work zone and is designed with horizontal joints. SCARA robots are able to operate faster than equivalent Cartesian robots.

Get Price -

THERMAL ANALYSIS OF THE ROBOT SUPPORTED BELT GRINDING .

Keywords: industrial robots, belt grinding, thermal analysis 1. ... certain cut geometry (external cylindrical grinding, plane grinding, etc.) and are very rarely ... function of all process parameters. The quality of the work piece surface is strongly influenced by the

Get Price -

Machinery

· Nagel automated compact robot honing cell ... NUM has added noncircular grinding functionality to its NUMgrind cylindrical grinding software, ... Vollmer has equipped its VPulse 500 wireerosion machine with additional functions to dress diamond grinding wheels using erosive methods.

Get Price -

Cylindrical Coordinate System | Overview and Significance

Cylindrical Coordinate System is widely used in Engineering and Science studies. In this article, let us revive it from the point of view of Electromagnetics. Do not miss our EMT Courses for GATEEE and GATEEC at special pricing [up to 50% off] for GATE 2022.

Get Price -

Grinding Wheel: A Definite Guide For You (With PDF)

Cylinder or wheel ring Grinding wheels: A cylinder wheel has no center mounting support but has a long wide surface. Their width is up to 12″ and is used purely in horizontal or vertical spindle grinders. This is used to produce a flat surface, here we do grinding with the ending face of the wheel. Tapered Grinding wheels:

Get Price -

Investigation of cycle time behavior in the robotic ...

· Using the two equations that describe robot's actual trajectory (Eq. 8 and Eq. 12), the equation for the face grinding process cycle time ( T) can be derived as a function of the process parameters, as follows: (13) T = t 1 τ ln Δ r 2 U 1 τ ( 1 e t 1 τ) where Δ r 2 in Eq. 13 denotes the width tolerance of the part.

Get Price -

Five Types of Industrial Robots And How To Choose The Best ...

· Robotics can be narrowed down to five types: Cartesian, Cylindrical, SCARA, 6Axis and Delta. Each has specific elements (speed, size, workspace) making them ideal for certain appliions. Knowledge of each type can help machine designers choose the .

Get Price -

2. Industrial Robot Functionality and Coordinate Systems ...

Robot anatomy. Robot anatomy stands on the joints and links, which are basic in forming the coordinate systems of industrial robots. Joints provide relative motion. Links are rigid members between joints. Robot manipulator consists of two sections: Bodyandarm – for positioning of objects in the robot.

Get Price -

Automation Options | Grinding Systems | GCH Machinery

Automation Options. Automation modules can ease the challenges faced by manufacturers including everincreasing production rates and operator fatigue. Aware of our customers' demands for improved productivity from their grinding systems, GCH Machinery offers a number of options to automate machine operation. Gantry style load/unload systems.

Get Price -

Grinding Machine

· Grinding Machine Parts and Functions. 6) Wheel Head :It is the compartment that is moved vertically up or down using a traversing wheel called Vertical Feed Hand Wheel .We move this wheel head so that the grinding wheel can touch the workpiece. 7) Three types of traversing wheel : i) Hand Traversing Wheel : This traversing wheel is used to move the table is horizontally left and right .

Get Price -

Grinding machine ppt

Cylindrical grinder • Cylindrical grinder, which includes both the types that use centers and the centerless types. A cylindrical grinder may have multiple grinding wheels. The work piece is rotated and fed past the wheel(s) to form a cylinder. It is used to make precision rods, tubes, bearing races, bushings, and many other parts. 9.

Get Price