-

Practical 1 : Ball Milling | TF Lab 1

· Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture. Introduction: 'Ball milling is a method used to break down the solids to smaller sizes or into a powder. A.

Get Price -

Technical Report: Optimization of Comminution ...

· Implementation of this technology in the midwestern iron ore industry, which grinds an estimated 150 million tons of ore annually to produce over 50 million tons of iron ore concentrate, would save an estimated 1 x 10{sup 13} BTU/year.}, doi = {/887498}, url ...

Get Price -

Energy and Cost Comparisons of HPGRbased Circuits | E MJ

Thus, there was considerable scope to reduce the ballmill power consumption by using smaller ballmill grinding media. However, for a final grind of 75 μm, the reported power values for both HPGRball mill and SABC circuits were based on JKSimMet modeling alone. In these cases, the previously fitted model was optimized through process design changes (media size, transfer size, cyclone ...

Get Price -

Coefficients Of Friction

When calculated the torque to be transmitted it is generally sufficient to use the simple equation. T= μ. π.d c /2. d= the shaft diameter L is the length of the interference joint. The surface pressure P c is calculated typically using lame's equation. Calculators are available for obtaining the transmitted toque very conveniently. Tribology abc Engineers edge press fit calculatgor ...

Get Price -

Processing

· Each mill measures about 12 metres in diameter and has an internal volume of 1,220 cubic metres. As the AG mill turns, the ore crushes against itself and breaks apart. From the AG mills, the ore travels to the primary magnetic separators where the iron is drawn away from the waste material before it's screened and fed into the ball mills.

Get Price -

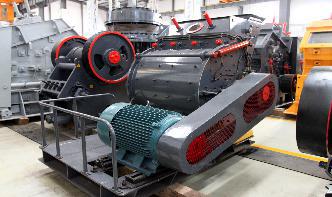

Size Reduction Equipment

•It is desired to crush 10 ton/hr of iron ore hematite. The size of the feed is such that 80% passes a mm screen, and 80% of product a screen. Calculate the gross power requirement for wet grinding and dry grinding. Work index of Hematite is [Ans ] Size Reduction Equipment A. Crushers (Coarse and Fine) 1. Jaw Crusher 2. Gyratory Crusher 3. Crushing Rolls B. Grinders ...

Get Price -

MINERAL PROCESSING LABORATORY MANUAL

Crushing of Ore in a roll crusher, and Determination of average size by sieving. 1618 7 To determine the reduction ratio, theoretical capacity, and actual capacity of a roll crusher. 1921 8 To study the effect of grinding with grinding time in Ball mill. 2225 9 To study the effect of grinding with frequency (RPM) in Ball mill. 2628 10

Get Price -

optimization of iron ore ball mill pdf

Iron Ore Ball Mill Pdf Ball mill for iron ore ball mill for grinding iron mill for grinding iron ore with capacity of 130tph and iso certifie ball mill is a key equipment to grind the crushed materials, which is widely used in the manufacturing industries, such .

Get Price -

A discussion on the measurement of grinding media wear ...

· The mills most used in mineral processing plants are the tumbling mills – a cylindrical metal housing, internally coated, and partially filled with ore, water and grinding media, which rotates around its horizontal axis. The grinding media may be the ore itself (autogenous grinding), bars, balls, or cylpebs, or even the ore itself together with a small amount of balls (semiautogenous ...

Get Price -

iron ore ball mill grinding media calculation

Ball Mill Grinding Media Calculation In Iron Ore. iron ore ball mill grinding media calculation formula The flow sheet has been developed largely based on an 8 tonne pilot scale test done at ALS iron ore technical . More Info

Get Price -

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill ...

Recognize important considerations in ball mill selection. Reading Lecture. In ball mills, steel balls or hard pebbles to break particle based on impact and attrition. A rotating mill charged with media and ore is lifted against the inside perimeter. Some of the media falls .

Get Price -

Grinding control strategy on the conventional milling ...

fed in ratio to the ore feed mass. The rod mill discharge is pumped, without any further water addition, to the first ball mill. The ball mill discharges to a sump where water is added before the slurry is pumped to the first cyclone (Cylcone 1). See Figure 1 for a schematic of the process flow. The slurry stream is classified at Cyclone 1 with the overflow going to the flotation circuit ...

Get Price -

Grinding Media

Alumina Balls and Satellites. Union Process is the one source for 90%, 94%, % and % alumina media. 90% alumina is available in satellites and rod/cylinders. 94% alumina balls have excellent wear resistance with higher impact strength to save running costs with less contamination. They have great wear rate generally better than 90% or 99 ...

Get Price -

Angle of Material Recommended Material Density Repose ...

Chips, paper mill 2025 0° 4 . Chips, paper mill, softwood 1230 0° 4 . Chips hogged, fuel 1525 0° 4 . Chrome ore (chromite) 125140 3044° 3 . Cinders, blast furnace 57 35° 3* 1820 . Cinders, coal 40 35° 3* 20 . Clay calcined 80100 0° 3 . Clay, ceramic, dry, fines 6080 3044° 3 . Clay, dry, fines 100120 35° 3 2022 . Clay, dry, lumpy 6075 35° 3 1820 . Clover seed 48 28° 2 15 ...

Get Price -

Consumption of steel grinding media in mills – A review ...

Grinding media consumption is one of the major operating costs in mineral processing industry; it was found that the consumption of media in ball mills during grinding operation can be up to 50% ...

Get Price -

Iron Ore Ballmill Grinding Media Calculation

Ball Mill Grinding Media Calculation In Iron Ore. Ball mill grinding media calculation in iron ore ball mill grinding media calculation in iron ore Ball Mill Instruction Manual (PDF) BICO Inc The F C Bond Ball Mill is a small universal laboratory mill used in calculating the made in the Bico Mill rurming at 70 revolutions per minute with a charge of285 iron balls ranging in

Get Price -

Lecture 12: Exercise on mineral processing Contents

calculate the tonnage of Problem6: Do yourself A Calculate. A floatation circuit consists of rougher‐cleaner circuit. cleaner tail. and grade in the concentrate is 98% and 89% respectively. Calculate flow. Solution Material balance at steady state of rougher

Get Price -

Quality Grinding Steel Balls Grinding Media Balls ...

Low break rate B3 ore grinding steel balls, Industrial ball mill grinding media; High Chrome cast grinding steel balls, Surface hardness HRC 60 TO 68 ; Industrial Low Chrome cast grinding steel balls for poland cement Plant; No breakage High Chrome Wear Resisting Cast Iron Balls for Mining; Who We Are . Introduction. Established in 2000, We Jinan Zhongwei casting and forging grinding ball ...

Get Price -

Estimated Water Requirements for the Conventional ...

water usage. The crushed ore is transferred to a semiautogenous (SAG) mill or ball mill where the ore is further reduced in size. Water is added to the ball mill, in which a slurry that usually contains from about 20 to 55 percent solids is produced (Singh, 2010; International Mining, 2011) (see fig. 2). The

Get Price