-

Coal: Advantages and Disadvantages Explained

Mar 15, 2021 · Coal Mining is a Big Business. There are 52 working coal mines in the US, 600coal generating facilities, and 1100 manufacturing facilities; Between them, they employ 130,000 people. A further 7,800 power plant units across the globe rely on coal power.

Get Price -

ASIA PACIFIC

The final product is a tough, flexible material with extremely high bond strength that is resistant against acids, alkalis, brines and many solvents. Ideal for grouting/injection coal and adjacent strata, sealing of injection anchors and stabilisation of debris.

Get Price -

Surface miner at Mozambique coal mine a ...

Jul 03, 2015 · It is capable of mining rock with an unconfined compressive strength of up to 50 MPa at a cutting depth of up to 830 mm in softrock mining. ... and waste impact on the quality of the final ...

Get Price -

mining process from rock to final product

mining process from rock to final product; The Hard Rock Mining Process. The Mining Process – Waihi Gold. 1. Mining – open pit and underground. To define the ore from the waste rock, samples are taken and assayed. Assay results are used to mark out areas of ore and ...

Get Price -

Coal Types, Formation and Methods of Mining

In addition, strip mining is ecologically very destructive unless the mining company makes a conscious effort to restore the countryside. Strip mining is the process of scraping the coal from the top surface of the ground. The second phase in the evolutionary development of coal is lignite. Lignite is found in great quantities in the Western ...

Get Price -

mining

As with coal mining, caving methods are often used in ore mining. Caving methods in ore mining require that the rock above and around the ore body be weak so that it will break into a fractured mass, and they also require that the ore fracture into small pieces. Caving applies best to wide, vertically oriented, veintype ore bodies.

Get Price -

mining process | Stone Crusher used for Ore Beneficiation ...

May 20, 2012 · Small scale gold mining equipment. Small scale gold mining equipment for a gold mining plant is relatively investing less. SBM Company is the professional small scale gold mining equipment manufacturer and exports complete small e scale gold miningequipments all over the world, such as Tanzania, South Africa, Ghana, Zimbabwe etc.. Our scale gold mining machines through the .

Get Price -

(PDF) South African Coal Mining Industry: SocioEconomic ...

The socioeconomic attributes of coal mining in South Africa According to the respondents the coal mining impacts on the society and the general economy of the country are observed from the early days of pick and shovel coal mining to present highly mechanised mining process. The coal use for space heating and cooking from the early days to ...

Get Price -

Coal Mining, Kentucky Geological Survey, University of ...

Sep 18, 2019 · Coal Mining. According to the Kentucky Department of Mines and Minerals, million tons of coal was mined in Kentucky in 2000; 62 percent (81 million tons) was from underground mines and 38 percent (50 million tons) was from surface mines. There were 264 active underground mines and 240 active surface mines in Kentucky in 2000.

Get Price -

Development of Sustainability Assessment Method of Coal Mines

Coal mining plays a key role in economic ... problems in the process of underground coal extraction such as high temperature, humidity, coal and silica dusts, harmful gases, the rock stresses, and ...

Get Price -

Coal waste

Jun 07, 2021 · Coal mining and coal combustion in power plants produce several types of wastes: The mining process itself produces waste coal or solid mining refuse, which is a mixture of coal and rock.; The mining process also produces liquid coal waste, which is then stored in impoundments.; Pollution control equipment used for coal combustion produces coal ash or fly ash, as well as fluegas ...

Get Price -

Baralaba North continued operations project | Environment ...

The project would be on a new mining lease (ML) 80201 and within the existing ML80169 and ML80170 and would cover approximately 2,498 hectares. The mine would produce up to million tonnes per year (Mt/y) of runofmine (ROM) pulverised coal injection coal to produce up to /y of product coal .

Get Price -

The Mining Process

The Mining Process. Finding new mineral reserves is critical to the success of our company. Loing, extracting and processing these natural resources is a multiyear process that involves complex scientific, environmental and social planning. Newmont mission is to build a sustainable mining business while leading in safety, environmental ...

Get Price -

Wirtgen surface miner increases ...

Aug 21, 2015 · Wirtgen surface mining is used as triedandtested technology in numerous coal mining projects, and a sixmonth trial phase with defined target performance levels was agreed upon between NAC and Wirtgen. The 4200 SM achieved the projected cutting performance of up to 3,000 t/h in the tough everyday mine environment.

Get Price -

Coal Mining –The 2 Most Basic Techniques Of Extraction ...

Mar 25, 2018 · Once the coal has been removed from the mine, from either of the techniques, it is taken to a preparation plant. This plant is loed near the site of mining. Here the coal is cleaned and processed. All the unwanted material like dirt, sulphur, ash, and debris is removed from the coal. This increases the value of the coal. After cleaning, the ...

Get Price -

Coal: A Complex Natural Resource

Coal—A Complex Natural Resource. An overview of of factors affecting coal quality and use in the United States. Coal is abundant in the, is relatively inexpensive, and is an excellent source of energy and byproduct raw materials. Because of these factors, domestic coal is the primary source of fuel for electric power plants in the ...

Get Price -

the elements and compounds being mined in coal mining ...

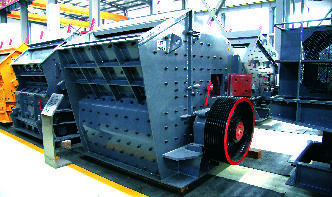

High Capacity Used Industrial Mini Small Size Sand Coal Stone Rock Gold Ore Glass Bottle hammer crusher. 1,713 rock hammer crusher products are offered for sale by suppliers on, of which crusher accounts for 42%, mining machinery parts accounts .

Get Price -

coal mining

Choosing a mining method. The various methods of mining a coal seam can be classified under two headings, surface mining and underground mining. Surface and underground coal mining are broad activities that incorporate numerous variations in equipment and methods, and the choice of which method to use in extracting a coal seam depends on many technological, economic, and social factors.

Get Price -

How Coal Works | Union of Concerned Scientists

Dec 15, 2017 · Two dominant methods account for the vast majority of underground coal mining: "room and pillar" and "longwall" mining.. In room and pillar mining, seams of coal are partially mined, leaving large pillars of coal intact to support the overlying layers of rock. When finished, miners practice "retreat" mining, extracting as much coal as possible from the remaining pillars as they ...

Get Price -

Blasting Principles

Mining to access the orebody (a term used in both surface and underground mining). Dilution. The undesirable lowering of ore grade by mixing waste material during blasting and mining. Dragline. A large excavation machine used mainly in surface coal mining to remove overburden (layers of waste rock and soil) covering a coal seam.

Get Price -

The 5 Stages of the Mining Life Cycle

Apr 29, 2019 · The final step in production is smelting; this process involves melting the concentrate in a furnance to extract the metal from its ore. The ore is then poured into moulds, producing bars of bullion, which are then ready for sale. 5. Closure and reclamation. The fifth and final stage in mining operations is closure and reclamation.

Get Price