-

The Cement Manufacturing Process

· Laboratory XRay Fluorescence (XRF) systems are used by cement QC laboratories to determine major and minor oxides in clinker, cement and raw materials such as limestone, sand and bauxite. Read Analysis of Clinker and Cement with Thermo Scientific ARL OPTIM'X WDXRF Sequential Spectrometer to learn why XRF is the technique of choice for elemental analysis in cement industry.

Get Price -

Use of recycled aggregates for cement production ...

The raw meal also contained limestone and corrective materials (bauxite and iron oxide) but marls were not used. The clinker produced contained free lime rates similar to the standard clinker production. Conclusion. Replacement of Portland clinker raw materials by RA is promising but challenging because of the variability in the RA composition.

Get Price -

Cement Clinker Manufacturing Process with Reactions ...

The raw materials are ground in the raw mill where the particle size is reduced on a 90 um sieve and then transferred to a homogenization silo to ensure the production of .

Get Price -

clinker raw materials

CEMENT RAW MATERIALS International Cement Review. The quality of cement clinker is directly related to the chemistry of the raw materials used. Around 80–90% of raw material for the kiln feed is limestone. Clayey raw material accounts for between 10–15%, although the precise amounts will vary.

Get Price -

Clinkerization

Sulphur in raw meal increases SO x emission and causes buildup in preheater. Sulphates needs to balance alkalies in kiln system. Excess sulphates can be calculated as: Sulphate Excess= SO x K 2 x Na 2 O (g/100kg clinker) Cl chlorides can come from raw materials and fuel.

Get Price -

Use of stabilized EAFD as a raw material in the production ...

As used herein, the term "cement raw materials" include limestone, clay, and sand, and any other known cement raw materials including iron sources, such as iron ore, mill scale, and coal ash. Since stabilized EAFD is not heretofore known to be a raw material for cement clinker production, stabilized EAFD is not included in the term "cement raw materials," as used herein.

Get Price -

clinker cement raw material

Raw Material Substitution Cembureau. The main raw material used in cement production has traditionally been limestone Limestone is abundantly available, For example, sewage sludge has a low but significant calorific value, and yields ash that becomes a raw material used to make clinker In recent years, about 34% of raw materials used in the ...

Get Price -

Cement Plants: Raw Materials

Materials used in the Cement Industry in Britain and Ireland Almost any mineral can be used in a cement rawmix, provided that the bulk composition of the mixture will produce the desired calcium silies and fluxes (see clinker ), and provided that certain deleterious components are minimized.

Get Price -

Reducing the Clinker Factor – Part 1 | World Cement

· To that end, Solidia's patented processes for producing sustainable cement and concrete use the industry's existing infrastructure, raw materials, formulations, production methods and specifiions. Motivating a market. The incentive to 'reduce the clinker .

Get Price -

raw material used for making cement clinker

Raw Material Used For Making Cement Clinker Gold Ore Name Raw Materials Used For Making Cement. Nov 24, 2006 limestone, the principal raw material in portland cement clinker production is geologically abundant and hence it forms the basis for the global binder portland cement cem iy and large, the raw materials used to make nonportland cements are et

Get Price -

A Review On Environmental and Health Impacts Of Cement ...

The main component of cement is clinker, which is produced from raw materials, such as limestone and clay. [8]. Limestone supplies CaCO 3 for the cement production. Silica, alumina, and iron are considered to be other raw materials. The lime stone used for cement manufacturing contains 7590 % of CaCo 3 and remainder is MgCo 3

Get Price -

Use of Selected Minerals as Secondary Raw Materials in ...

Keywords: cement, raw mix, mineral additions, clinker, structure Abstract. The use of selected secondary materials for improving the reactivity of cement raw mix, is a challenging subject. It is known that certain foreign elements exert a considerable effect on the cement raw mix burnability and clinker structure, even at low concentration.

Get Price -

Cement Manufacturing

raw materials, but the highly alkaline conditions in the kiln can absorb up to 90% of the sulfur oxides. Heavy metals may also be present in the raw materials and fuel used and are released in kiln gases. The principal aim of pollution control in this industry is to avoid increasing ambient levels of particulates by minimizing the loads emitted.

Get Price -

Cement

· Raw materials are ground, mixed with water to form slurry, and blended. 23. 3. Burning changes raw mix chemically into cement clinker. 24. 3. Burning changes raw mix chemically into clinker. Note four stage preheater, flash furnaces, and shorter kiln. 25. Pyro Processing 26. 4. Clinker is ground with gypsum into portland cement and shipped. 27.

Get Price -

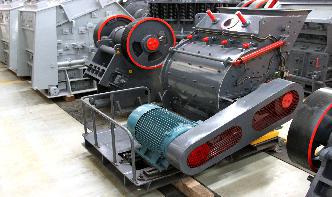

Preparation Of Cement Raw Material | Cement Mill, Cement ...

The raw material production of cement plant can be classified into four steps: crushing, grinding, mixing and homogenizing. Crushing: the limestone and other materials are crushed into small pieces by cement crusher, such as hammer crusher, cone crusher, jaw crusher, impact crusher, etc. Mixing: according to the requirement of clinker, compound ...

Get Price -

Cement composition and classifiion

· Proportioning of materials. Portland cements can be modified easily, depending on the raw materials used and the process used to combine them. Proportioning of the raw materials is based on a series of simultaneous calculations that take into consideration the chemical composition of the raw materials and the type of cement to be produced: American Society for Testing and Materials .

Get Price -

chemical analysis of cement raw material and of the clinker

· Combinability of raw materials used to make Portland cement. . Clinker composition is evidently one of the key factors which determine cement quality. . of limestone and a source of clay and that he knows the chemical composition of each. »More detailed

Get Price -

Cement raw mix characteristics

· The rheological properties of the clinker melt control parameters, such as clinker mineral formation, clinker coatability, clinker fineness, cement strength, and refractory depth of infiltration. It is then very important to keep fuel and raw materials properties and .

Get Price -

Utilization of Iron Ore Tailings as Raw Material for ...

· Portland cement clinker production consumes large amounts of natural resources (limestone, clay, etc.), and clay has been widely used as traditional aluminasilie raw material for good reasons . Cement industry has undergone a tremendous development in the past decades, but it causes excessive exploitation of clay resource and considerable environmental damage.

Get Price -

Modelling the cement process and cement clinker quality ...

· This paper presents a recently developed simulation model that can be used as a tool for evaluating sustainable development measures for cement and lime production processes. Examples of such measures are introducing new combustion technologies such as oxyfuel combustion, using biomass fuel and using alternative materials in the raw material feed. One major issue when .

Get Price