-

Double roll crusher | Henan Deya Machinery Co., Ltd.

· Double roll crusher technical data. The determination of production capacity is based on the following conditions. a) compressive strength of crushed ore ≤ 120 MPa. b) surface moisture ≤ 2%. c) Ore density of t/m3. d) continuously and evenly feed over the full length of the roll. The qualifiion rate of the discharge particle size ...

Get Price -

Edge RS1500 Roll Sizer (Double Roll Crusher)

The EDGE – ROLL SIZER offers a new concept in mineral sizing solution. The EDGE RS1500 roll sizer has been designed for the secondary and tertiary crushing of mediumhard, sticky and soft materials such as coal, lignite, clay, limestone and other bituminous and subbituminous materials.

Get Price -

Home

The crushing and drive technology of the Crush + Size double roll crusher ensures crushing results far beyond the previously known limits of a double roll crusher. Customer benefits in focus The technological advantage helps operators to streamline existing processes in stationary and mobile appliions and to achieve a higher usable result.

Get Price -

Maintenance of Double Roller Crusher

· Today, we will talk about the maintenance of double roller crusher. 1. It is strictly prohibited to enter unbreakable materials. If necessary, iron remover can be added or other measures can be taken before feeding hopper. If it enters the machine, it should be taken out immediately. 2.

Get Price -

Design, Fabriion and Testing of a Double Roll Crusher

Figure 1: Double roll crusher geometry Thickness of the RollFigure 1 is the geometry of a double roll crusher with a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped [4], [5]. For rolls that have equal radii and length, tangents drawn .

Get Price -

Double Roll Crusher

Bevcon toothed double roll crushers are equipped with two identical crushing rolls rotates towards each other. These crushers are ideal at different stages of crushing primarily envisaged to generate very less fines. Hence the crushing ratios are limited to 4 :1. Since both rolls rotate in same speed, there is no relative motion between roll surfaces.

Get Price -

How to Improve the Production Efficiency of Double Roll ...

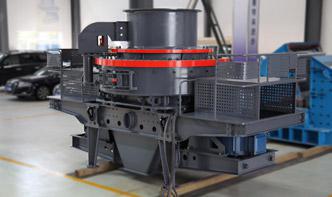

· Double roll crusher is one of the common crushing equipment in sand production line, with the characteristics of small size, low noise, simple structure, easy to maintain, etc. For the major enterprises, improving the production efficiency of the roller crusher has .

Get Price -

Mineral Sizers,Twin Shaft Mineral Sizers, Double Roll ...

EXCT is the world's most professional manufacturer of double roll crushers. EXCT sizers are designed and manufactured to be the highest efficient and lowest maintenance costs in service life. EXCT sizers provide primary, secondary and tertiary crushing operations for many kinds of mineral, such as coal, salt, gypsum, phosphate, limestone ...

Get Price -

About Us – CPC – Crushing Processing

About Us – CPC – Crushing Processing. The CPC Crushing Processing is a specialist company focused on crushers for coals and minerals, as well as machines for several other industries. CPC can draw on lots of experience, since it was founded by Bruno Goetz, former Technical Director of Aubema . When the former Aubema facility ...

Get Price -

Double Roll Crusher – Henan Victory Machinery Co., Ltd.

Double Roll Crusher is short for roll crusher or roll crusher. The roll crusher has simple structure and few over crushing phenomena. The tooth shape, size and arrangement on the roll surface can be changed with the material properties, and it can be used for medium and fine crushing .

Get Price -

Rolls Crusher for Sale

Roll Crusher for Sale The standard spring roll crusher have two horizontally mounted cylinders. The set is determined by spacing pieces (shims) which cause the springloaded roll to be held back on its sliding mounting from the solidly mounted roll. Modern rolls have both cylinders positively driven by separate motors, so that they rotate inward and downward. Rolls crush by nipping the feed ...

Get Price -

Roll Crusher Manufacturer Design | Williams Crusher

Double Roll Crushers produce a finer product at lower reduction ratios and capacities. Williams Roll Crusher Features HeavyDuty Drive Shafts Bearings. Oversized, heattreated, alloy steel shafts plus selfaligning, rollertype bearings assure long life and maximum use of power.

Get Price -

X BJD DOUBLE ROLL CRUSHER

The used BJD 60/50 double roll crusher mill is in fair to good condition and available immediately ex site UK. Complete with 2 x 22Kw drive motors the used BJD double roll crusher model type 60/50 comes with 2 smooth spare rollers and associated spare parts and control panel.

Get Price -

2PG400x250 Double Roll Crusher Machine

2 Roll crusher is also called double roll crusher, double teeth roll crusher etc. The surface of roller crusher are made of high manganese steel, which can stand up to heat treatment. Double roller crusher is suitable for rough and intermediate crushing of brittle materials in such industries as cement, chemical industry, electric power, mine, building materials and metallurgy.

Get Price -

Roll Crusher

Roll Crusher. For a given reduction ratio, singleroll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coal. Doubleroll crushers consist of two rolls that rotate in opposite directions.

Get Price -

Used Two Roll Crusher for sale. Sturtevant equipment ...

FAM x 5 ft Double Roll Crusher For 350 TPH 36 x 36 x 28 in lump feed Designed for 8 cu yd bucket dump Product, 95% 0 8 in Previously fed by 5 x 50 ft apron feeder (available separately) Heavy duty, lined crushing chamber designed...

Get Price -

Shumar Double Crushers

Double roller crushers segments. Double roll crusher segments wimmaasse nl shumar segment secondary crusher type pc126 csgp screen type double toothed roll crusher all shumar crushers have one fo the most important aspects of the crusher design is the correct segment get price crusher roll segments europe shumar double roll crusher all shumar crushers have two machined rolls to .

Get Price -

How a double roll crusher operates

How a double roll crusher operates Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, How a double roll crusher operates, quarry, aggregate, and different kinds of minerals.

Get Price -

Single Roll Crusher

Bevcon Single Roll Crusher is typically primary crusher. The crushing technique involves the operations like Impact, shear and compression. The material entered in the crushing chamber is struck hard against a rotor consisting of series of teeth mounted on a rotor. Material is crushed between teeth and a breaker plate consisting of hard liners.

Get Price -

double roller crushers segments

double roll crusher segments . Double Roll Crusher From American Pulverizer. American Pulerizer Double Roll Crushers are ideal for materials such as coal, clay, line where minimum fines are desired.

Get Price -

FAM – Crushers – Processing Technology

FAM designed crushers are used for crushing minerals, raw materials and other bulk commodities.. The types of crushing machines are distinguished by their working principles: by pressure, impact, hammer, or shear. In contrast to mills, crushers process the feed materials into grain sizes from coarse to .

Get Price