-

PAME | manufacturing process of cement ball mill zk mining ...

ball mill machine for cement manufacturing: Ball Mill,Dryer Machine,Rotary Kiln,Cement Mill,Rod, is a leading mining machinery manufacturing company in China We have engaged in the production of mining equipment for almost thirty years and our main products include ball mill, crushing machine, powder grinding machine and rotary kiln and they are well received in more than thirty countri ...

Get Price -

Cement mill

ball mill Ф1830×6400. horizontal for cement. ball mill. Ф1830×6400. Output: 7 t/h 16 t/h. The Ball mill Ф1830×6400 model is manufactured by Shanghai Joyal Machinery Co., and is a grinding plant that has been specifically developed as a component that is ideal for use in secondary grinding after crushing.

Get Price -

Cement Plant Equipment

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabriion with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

Get Price -

PPC Cement Manufacturing Process

After cooling, the clinker is mixed with pozzolanic materials and gypsum in a required proportion and then sent to the cement mill for final grinding. The cement powder is usually stored in cement silos, then bagged and stored in the warehouse. ... It is a Chinese company that specialized in manufacturing and exporting cement plants and cement ...

Get Price -

Matcon: Manufacturer and Supplier of Paper Mill, Cement ...

Matcon Industries is known as one of the reputed Business Enterprises, engaged in the manufacturing and supplying of Paper Mill Equipment, Cement Mill Equipment, etc. Moreover, the company also deals in Cement Mill Machine Spare Parts, Chemical Process Equipment, and Sugar Plant Equipment. The company is loed in the Ahmedabad city of Gujarat and has successfully established its name in the ...

Get Price -

Cement : Manufacture, Chemical Composition, Heat of Hydration

then fed together into a mill where the rock is ground until more than 85% of the material is less than 90µm in diameter. Manufacture of Portland Cement The wet process : The clay is mixed to a paste in a washmill a tank in which the clay is pulverised in the presence of water. Crushed lime is then added and the whole mixture further ground. Any material which is too coarse is extracted and ...

Get Price -

Cement

Cement is the main basic ingredient of readymix concrete. Whether in bags or in bulk, CEMEX provides its customers with highquality branded cement products for their construction needs. Cement is a fine powder, obtained from the calcination at 1,450°C of a mix of limestone, clay, and iron ore.

Get Price -

Manufacturing technology of segment cement mill

Basic and additional materials, and technologies which was represented at manufacturing mills for cement Topics: tehnologija izrade, tehnologija zavarivanja, mlin za cement, alati i strojevi., technology of manufacturing, technology of welding, mill for cement, tool .

Get Price -

CEMEX USA | Concrete Cement Manufacturing Company ...

Jun 18, 2021 · CEMEX is a global building materials company that provides high quality products and reliable service to customers and communities throughout the Americas, Europe, Africa, the Middle East, and Asia. We produce, distribute, and sell cement, ready .

Get Price -

Right Manufacturing Systems

You cannot afford to get the wrong concrete mix. That is why we have named our mixers, batch plants, and silos "Mix Right", because they are designed and built to mix, batch, and operate right every single time. RMS Performance Sheet. DUNS#. . CAGE. 5ZBV2. NAICS. 33120, 327320, 327390, 238990, 423810.

Get Price -

Basic Process of Cement Manufacturing | HeidelbergCement ...

Raw Mill Cooler. Preheater and Kiln. Blending and Storage Silo Clinker storage. Grinding. Packing For details about Basic Process of Cement Manufacturing, refer toCement Manufacturing Process ...

Get Price -

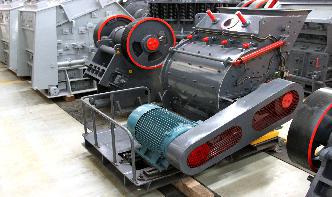

function of ball mill in cement manufacturing process

Cement manufacturing, ball mill, rotary kiln, cement mill,this is the heart of cement manufacturing process in dry process technology, the homogenized raw meal from the silos are heated to temperatures around 1000 deg c in the preheater and calciner Of Ball Mill In .

Get Price -

Manufacturing Process Of Cement Mill Plant Zenith

Cement Mill Plant for cement making process, cement production process. Main Equipment In Cement Mill Plant. Zenith engineers has been the recipient of many national and international export awards, acknowledging the superior standard and world acceptance of both the organisation and the products.

Get Price -

About Us

Premier Cement Mills Limited is one of the fastest growing cement companies in Bangladesh. It was incorporated back in October 14, 2001 as a private limited motto is to always strive to ensure good quality and we market our product under the brand name "Premier Cement".. Premier Cement strives for sustainable growth and aligns its development strategies accordingly.

Get Price -

Manufacturing Of Cement By Dry And Wet Process

Jan 22, 2020 · Storage and Packing: As cement comes out from grinding mills, it is collected in a hopper and taken in bucket elevator for storage in silos. The cement from silos is packed by machines in bags. Each bag of cement contains 50 kg or m 3 of cement. Now let's know the manufacturing of cement by the dry process

Get Price -

manufacturers of cement grinding mills 6kemg

Cement mills and raw mills for high throughput rates. High throughput rates permanent plant availability optimized maintenance concepts – features of the MVR mill and the patented MultiDrive ® enabling Gebr Pfeiffer to meet the ever rising expectations of the industry Thanks to the innovative drive and active redundancy an unintended stop of the grinding

Get Price -

Manufacturing process | Lafarge

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km. The limestone is excavated from open cast mines after drilling and blasting and loaded onto dumpers which transport the materials and unload into hoppers ...

Get Price -

Cement | FUCHS LUBRITECH

Whether your appliions involve the lubriion of crushers, mills, grinding rollers, kilns or excavators, FUCHS is the strong and reliable partner for you, providing solutions for all requirements of the cement industry including all relevant approvals.. We want your machines to perform at highlevel – every day. With FUCHS, you can enjoy the full range of highperformance lubricants ...

Get Price