-

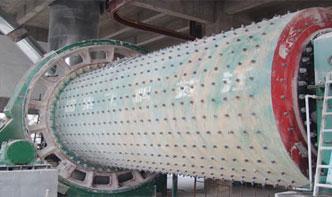

Ceramic Ball Mill – Machinery()

Ceramic Ball Mill is mainly used for mixing and milling materials, with even output fineness and energysaving. Not only the wet mill, but also dry mill. The machine can use the different lines according to the product requirement to satisfy different requirement.

Get Price -

: ceramic ball

2pcs Full Ceramic ZrO2 Sealed Bearing 68032RS,High Precision Miniature Bearings,Wearproof,White Ceramic Ball Bearing for Machinery Manufacturing,17x26x5mm 24 . 69 5% coupon applied at checkout Save 5% with coupon

Get Price -

Energy Saving Ball Mill|Cone Ball Mill|Tube Ball Mill ...

Xinguang Mining Machinery is a professional mining solutions and equipment manufacturer. We provide mining equipments such as cone ball mill, tube ball mill, dry magnetic separators, wet magnetic separators, gold/copper/hematite separation machine, etc.

Get Price -

CERAMIC BALL MILL_ZK Ball Mill_Rotary Kiln_Grinding Equipment

Ceramic type ball mill (ceramic ball) is mainly used for mixing of the material, grinding, the fineness of the product is uniform, saving power. Both dry grinding, wet grinding can also be. The fineness of the grinding operation, relying on the polishing time control themselves.

Get Price -

Ball mill,Ball mill machine,Saving Cone Ball Mill,china ...

Energysaving ball mill, grinding mill is an efficient tool for grinding many materials into fine powder Used to grind many kinds of mine and other materials Widely used .

Get Price -

Ball Milling The Role of Media and Bead Mills

The media can consist of either stainless steel, glass, or ceramic materials. The higher the bead hardness or density, the greater the collision force. The ballmilling process uses a higher concentration of grinding media to mill base in which the chambers are designed to maximize the energy transfer. Bead Milling: The Dispermat SL model line

Get Price -

QINGDAO AOKTEC IMPORT EXPORT CO., LTD.

Zibo Aoktec New Material Co., Ltd. is a hightech enterprise specializing in RD, design, manufacture and sales of alumina ceramic products. it covers an area of over 20000 Square meter, and the total investment is more than RMB50 millions. There are two kilns, 16 sets big ball mills, 20 sets isopressing machines, advanced lab, a full set of ...

Get Price -

china factory saving energy ball mill small ceramic ball

Ceramic Ball mill, ball mill for feldspar, ball grinding ... Ceramic Ball mill. Ball mill is the key equipment for grinding after crushing is widely used in the manufacture industries, such as cement, feldspar, silie ore, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics.

Get Price -

juggling 3 ball mills mess Mining Machinery Manufacturer

3. TERMINATION Longest Time Juggling Three Balls In Mills Mess Pattern While Blindfolded Tags: juggling, ball, juggle, blindfold, mills mess. Comments. Post A juggling pattern or juggling trick is a specific manipulation of props during the practice of 3ball Mills Mess, siteswap: 3. 3 .

Get Price -

Ceramic end mills take the heat in HRSA machining

Ceramic tools retain their hardness at the high temperatures associated with milling heat resistant super alloys (HRSAs). As a result, 20 to 30 times the speed can be achieved in comparison with solidcarbide tools, delivering considerable potential for increased productivity. A stable setup is advised, without coolant appliion as it would ...

Get Price -

CERAMIC WEAR LINING | CERAMIC GRINDING BALLCERAMIC .

CERAMIC GRINDING BALL 【Applicable equipment】 Ball mill Stirred mill, Splittings machine,Polishing machine, Sand mill etc. 【Product Features】 Low wear loss, High hardness, Corrosion resistance,Anti impact,Economical and Practical. more

Get Price -

Product literature and other information from Greenleaf ...

Excelerator ® Ball Nose. Greenleaf's line of Excelerator ® ball nose mills features patented geometries designed to maximize your productivity and improve tool life. Greenleaf's ball nose mills are the only ball nose end mills on the market designed to accept either carbide or ceramic inserts, making extreme appliions profitable.

Get Price -

china factory saving energy ball mill ceramic ball mill liners

ceramic ball mill dry grinding machine iraq wet ball mill ... The ceramic ball mill is a ball mill with a ceramic substrate. It is a new type of energysaving ball mill that can be used for grinding various materials, both dry and wet. The machine can be used according to different product types to .

Get Price -

Why use ceramic lining as ball mill liner?

Sep 27, 2021 · The appearance of ceramic lining brick is fine white, and between two lining bricks, the gaps are connected with the mother button to ensure the connection strength. Its main component is high quality alumina, high whiteness, no adverse effects on the quality of grinding materials. There are five kinds of ceramic lining bricks for ball mills, rectangular brick, trapezoidal brick, half ...

Get Price -

Ball Mill

The enery saving ball mill head and transmission part are made of cast steel; Reinforced bearing with more than 5 years service life. Cement Mill Xinguang provide verious kinds of ball mills, such as large cement mill, Small/Medium cement mill, dry latticetype cement mill, wet latticetype cement mill.

Get Price -

Ball Mill Loading

Ceramic Lined Ball Mills. Benefits of Tumble Milling: HIGH EFFICIENCY – Due to the relatively slow rotational speed but large mass of media, more of the energy goes into milling and less wasted as heat. Slice Mill™ Slice Mills™ are identical to the Ball Mills and Ceramic Lined Mills in diameter and design The only difference is that they ...

Get Price -

Small Stirred Ball Mill

Small Stirred Ball Mill. Appliion: It's widely applied in fields of zirconia silie, zirconia, alumina oxide, ceramic, chemical, electronic material, magnetic material, papermaking, painting, nonmetal minerals, new materials, coating, graphite, calcium carbonate, medicine, and so on. Stirred ball mill mainly consist of jar with inner ...

Get Price -

How to choose ceramic grinding media for your ball mill

Jul 11, 2019 · In this trend, 10000L grind mill is necessary to gold, silver, copper, iron, molybdenum, nickel mine, meantime the small size of ceramic grinding media is basic in wet grinding process for these types of mills such as ball mill, horizontal mill, vertical mill etc. Pingxiang Ceramic Co.,ltd is Ceramic Grinding Media manufacturer.

Get Price -

ball mill,spiral classifier,flotation cell,magnetic ...

Ceramic Ball Mill Has Large Energy Saving Space 01 14, 2018. Ceramic ball mill is the necessary grinding equipment in ceramics factory, because it has larger energy consumption, so there is a larger space for saving energy and reducing consumption. Learn more. Key Project. ...

Get Price