-

Everything you need to know about flatteners and levelers ...

· The cold mill roll gap should start out being set to the same profile as the crown of the incoming hot mill product. Then, as the cold mill gap is adjusted to reduce the crown, the coil also will come out flatif the hot mill got the relationship between crown and flatness right to begin with. If the cold mill rolls or hot mill coils have too much crown, the mills will roll out the center ...

Get Price -

Somethin' Else | A content company

Somethin' Else is part of Sony Music Entertainment. Somethin' Else's audio team is in the SME Global Podcast Division based in New York, London and Los Angeles. We create hit podcasts and radio shows for audiences around the world and have production teams in the US and UK. Our socially led creative studio works with talent, brands and ...

Get Price -

United Nuclear

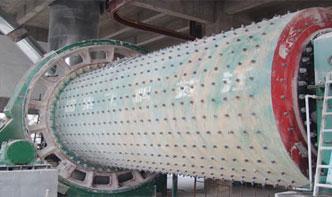

The mixing process for Black Powder is just as important as the formula. Black Powder MUST be made in a Ball Mill to work properly. A Ball Mill is a rotating drum with dozens of lead balls inside. The 3 chemicals are loaded into the Ball Mill, along with the lead balls, sealed shut and allowed to rotate for anywhere between 1 hour and 24 hours. As the Ball Mill rotates, the lead balls will ...

Get Price -

The EU wants to phase out palm oil from biofuels. Here's ...

· The EU ban disincentivizes efforts to ensure that palm oil production adheres to robust standards and practices in poorer countries. The Roundtable for Sustainable Palm Oil (RSPO) is a pathway to environmentally sound palm oil production. Its mission is to provide a valuable biofuel while implementing policies that ensure sustainable development, including research and development to .

Get Price -

Make Black Powder Quick and Easy — Skylighter, Inc.

· As it is right out of the ball mill, the mill dust will burn very rapidly with a "whoosh" if a small amount of it is lit with a fuse. To test this, lay out a short, 1/4inch wide line of the mill dust on a suitable outdoor surface. Be sure your larger container of mill dust is a long distance away from the line of powder. Put one end of a 3inch (at least) piece of visco safety fuse in the end ...

Get Price -

Milling Process, Defects, Equipment

Ball end mill; Chamfer mill; Face mill; Twist drill ; Reamer; Tap; All cutters that are used in milling can be found in a variety of materials, which will determine the cutter's properties and the workpiece materials for which it is best suited. These properties include the cutter's hardness, toughness, and resistance to wear. The most common cutter materials that are used include the ...

Get Price -

SOLUTIONS: HOMEWORK #6

out ball out −= −= = − =− Net energy transfer ... Assumptions 1 This is a steadyflow process since there is no change with time. 2 Potential energy changes are negligible. 3 The device is adiabatic and thus heat transfer is negligible. Properties From the steam tables (Tables A4 through 6) 1 /kg /kg 450 C 10MPa 1 3 1 1 = = ⎪⎭ ⎪ ⎬ ⎫ = = h v T P o STEAM m ...

Get Price -

How sugar is made

Mill sanitation is an important factor in quality control measures. Bacteriologists have shown that a small amount of sour bagasse can infect the whole stream of warm juice flowing over it. Modern mills have selfcleaning troughs with a slope designed in such a way that bagasse does not hold up but flows out with the juice stream. Strict measures are taken for insect and pest controls.

Get Price -

Metal Rolling

During the rolling process great forces act upon the rolls. Rolls will be subject to different degrees of deflection. In any particular metal rolling process, it is important to understand how these deflections will affect the rolls and hence the work being rolled. The rolls .

Get Price -

Drill And Bore With A Face Mill | Modern Machine Shop

· To find out when and why a shop might consider interpolation of a face milling cutter over traditional end mills, drills and boring tools to cut holes, we talked to Jeff Fox, training and appliions manager for Widia North America, a cutting tool maker; and Jim Turner, senior appliion engineer at Widia's parent, Milacron. They are using circular and helical interpolation of face milling ...

Get Price -

Speeds Feeds

Product Data Sheets User's Guides Service Bulletins Safety Data Sheets Wiring Diagrams. Speeds Feeds: Calculator Menu: Unit of Measure : Inch Millimeter Operation: Material: Cutter Material: HSS Carbide Cutting Speed: fpm (100300 fpm) End Mill Diameter : in: Spindle Speed: RPM Machine Max Cutting Edges: Chip Load: in/flute : Feed Rate: ipm SPECIAL OF THE WEEK: More .

Get Price -

The Mill | Creating the extraordinary | VFX | Colour ...

· Out with the coal, in with the green | Teaming up with Google Nest Renew to imagine a greener world . October 12, 2021. VFX Donatello returns in Saatchi Saatchi's latest Direct Line spot. October 4, 2021. Recent Awards. VFX The Mill secures three nominations for the 2021 Ciclope Awards. October 21, 2021. VFX Al Jazeera 'Channel Idents' picks up two awards at New York Festivals TV .

Get Price -

Learn About the Production Function in Economics

· Updated December 23, 2018. The production function simply states the quantity of output (q) that a firm can produce as a function of the quantity of inputs to production. There can be a number of different inputs to production, "factors of production," .

Get Price -

How ball bearings are manufactured | Engineering360

· Ball bearings are rolling element bearings that use balls to separate the bearing races and provide smooth, low friction motion in rotary appliions. Ball bearings are manufactured in hundreds of sizes, from the ultrasmall mm diameter bearing for use with miniaturized medical devices and micromotors, to bearings over 15 feet in diameter for use in heavy equipment.

Get Price -

Solow Growth Model

All firms in the economy produce output using the same production technology that takes in capital and labor as inputs. Therefore, the level of output (represented by Y), the level of capital (represented by K), and the level of labor (represented by L) are all linked through the production function equation Y = aF(K,L). The Solow Growth Model assumes that the production function exhibits ...

Get Price -

Wood prices are out of control. I went to a sawmill that ...

· Inside the mill, pine logs are stripped, cut, and sanded into lumber over a production line that spans hundreds of yards of belts, chains, and band saws spinning at 100 miles an hour.

Get Price -

Arcade | Music Production Software

It's available to use in all major recording programs and as a standalone Desktop app. Cloudconnected browser delivers new product Lines, Kits, and Samples daily, directly within the plugin — Download only the sounds you want. Transform and chop up Samples on the fly with Output's proprietary Modifiers.

Get Price -

CNC End Mill Guide

With all that said, most production work is done with carbide end mills. They are simple capable of higher material removal rates assuming you can spin them fast enough to use their full power. End Mill Sizes. Endmills are available in a variety of standard sizes both metric and Imperial. Even very tiny micromills can be had for machining extremely small features. Something surprising to know ...

Get Price -

Tin Mill Products

Tin mill products include electrolytic tinplate, electrolytic chromium coated steel (also referred to as tin free steel or TFS), and black plate, the uncoated steel. About 90% of tin mill products made in the world are used by the container industry in the manufacture of cans, ends, and closures for the food and beverage industry.

Get Price