-

® NP Series™ impact crushers

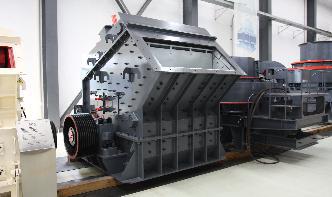

® NP Series™ HSI crushers consist of heavy rotor, wear resistant materials, and an optimal crusher chamber design. This combination has proven revolutionary in improving capacity and product quality, as well as in reducing operating and wear costs. ® NP™ crushers have a unique blow bar attachment system.

Get Price -

KLEEMANN Range of BLOW BARS

KLEEMANN blow bars YOUR SOLUTION FOR NATURAL STONE AND RIVER GRAVEL Natural stone River gravel Primary crushing level > Feed size > 250 < 450 mm > Reduced costs per ton > Increased blow bar service life > Less danger of breakage > Hardness: 55 – 56 HRC > Reduced costs per ton > Increased blow bar service life > Hardness: 60 – 62 HRC Secondary crushing level

Get Price -

HAZEMAG Tertiary Impact Crusher | HTI

The rotor of the Impact Crusher is generally the most stressed component during the crushing procedure. Depending on the crushing problem to be solved, two types of rotors are available for the HTI series. VR2Rotor maximum feed size: 70 mm ideal for the production of crushed sand fi tted with two rows of blow bars VR4Rotor

Get Price -

Chapter 9: Column Analysis and Design

Short columns fail by crushing at very high stress levels that are above the elastic limit of the column material. Compressive stress for short columns is based on the basic stress equation developed at the beginning of Chapter 5. • If the load and column size ( crosssectional area) are known, the ...

Get Price -

Blow Bar For Sbm Impact Crusher

Sbm Impact Crusher Blow Bars Blow bar for impact crusher. production capacity 30800 th . max input size 300800mm . more than 200 kinds of materials . stone crushing machine blow bar for impact crusher we provide customers with a variety of good quality construction and mining crushing equipment, and optimize the combination of various types of equipment to meet different ...

Get Price -

"Computer Aided Design of Jaw crusher"

mechanism used crushers are of three types namely Cone crusher, Jaw crusher and Impact crusher. Fracture occurs in the feed material when the strain developed in it due to sufficiently applied impact forces, pressure or shearing effect exceeds the elastic limit .Generally crushers are very rugged, massive and heavy in design.

Get Price -

5256T IMPACT CRUSHER

5256T IMPACT CRUSHER 5256T OPERATING SPECIFICATIONS 13'4" 58'8" 10'10" Total Weight 119,000 lbs. 53,980kg Directionally reversible, 54" (1,370mm) wide conveyor with impact bed and guide idlers

Get Price -

HOW TO SOLVE BLOWN FILM PROBLEMS

A third ratio, called the blow ratio (BR), is the increase of layflat width over die diameter. BR is used less frequently, but can easily be confused in conversation with the more common BUR. A blowup ratio greater than 1 indies the bubble has been blown to a diameter greater than that of the die orifice. The film has been thinned and

Get Price -

Chapter 9 Embankments

could impact adjacent structures (bridge abutments, buildings etc.), will generally require geotechnical borings for the design. The more critical areas for stability of a large embankment are between the top and bottom of the slopes. This is where base stability is of most concern and where a majority of the borings should be loed,

Get Price -

CHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE REDUCTION ...

• Size reduction is by compression, impact and shear and not by compression alone, as in the case of smooth roll crushers • Can accommodate larger particles than smooth roll crushers Crushing efficiency • Ratio of the surface energy created by crushing to the energy absorbed by the solid Grinders • Used to mill the grains into powder

Get Price -

exchange blow bars impact crusher

changing impact crusher breakers in zenith crusher hoe do you change blow bars on a impact crushercrusher wikipedia crushers may be used to reduce the sie or change the form impact crusher any lumps of material that still remain oversie are broken as the rotors chop through the fixed teeth of the breaker bar thereby achieving a three dimensional controlled product sie...

Get Price -

Basics of Retaining Wall Design

G. Reinforcing Bar Basics and US / Metric Conversions H. Reference Bibliography I. Notations and Symbols J. Glossary Index About the authors . . . HUGH BROOKS has been a consulting structural engineer for over 40 years and is a licensed civil and structural engineer in California. He has managed Retain Pro Software for over fifteen

Get Price -

I140RS IMPACT CRUSHER

IMPACT CHAMBER: CR032 Impact chamber Fully Hydraulically assisted apron setting and hydraulic apron release Manual raise inlet allowing extra inlet clearance 4 bar rotor Tool steel blow bars 2 High 2 Low Direct Drive via Clutch Drive belt tensioner wheel Blow bar lifting tool supplied Tip Speed range 3544 m/sec (115144 ft./sec ...

Get Price -

Blower Appliion Basics Blower Appliion Basics

calculation because there will likely be some small change in motor efficiency at the different operating point. This can usually be neglected for estimating power requirements. Static and Velocity Pressure: The energy of a fluid can be viewed as having two types of pressure: static pressure and velocity pressure.

Get Price -

IMPACT CRUSHERS

impact crushing plant, we have the optimum, innovative solution for your specific needs. 3. MILWAUKEE, INC. 4 SUPERIOR QUALITY, MORE PORTABILITY AND BETTER FEATURES The 4800 Series Impact Crushing Plants from Lippmann are the ultimate, completely selfcontained, easy to transport crushing plants

Get Price -

Impact Crushers NP Series Impact Crushers

NP Series impact crushers are characterised by a unique blow bar fixing system providing a higher degree of blow bars reliability. NP Series impact crushers have been designed to minimise maintenance and improve all adjustment operations. NP Series impact crushers deliver unbeatable performances in primary, secondary, tertiary

Get Price -

Blow Bar Impact Crushers

Enith Impact Crusher Blow Bars. blow bars for impact crushers Impact Blow Bars manufacturer enith is the best China Impact Blow Bars manufacturing Impact Blow Bars for sale provides all kinds of Crusher Spares parts Request Quotation The impact crusher parts mainly include impact crusher blow bars crusher rotors crusher liner plates and so on

Get Price -

Tips to maximize crushing efficiency

13/05/2019 · Feeding impact crushers. Size reduction in an impact crusher relies on energy being conveyed into the rock from the rotor, and it begins with your feed. The initial impact is responsible for more than 60 percent of the crushing action, with the remainder made up of impact against an adjustable breaker bar and a small amount of interparticle ...

Get Price -

(PDF) DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT ...

Fig. 1 A typical Impact crusher [6] Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotor. Here the rotor shaft is aligned along the horizontal axis. The input feeded material hits the rotating hammers of the rotor and due to this sudden impact it ...

Get Price -

Technical Specifiion Impact Crusher I120RS

IMPACT CRUSHER R SPECIFICATION: Rotor Size: ... Martensitic blow bars 2 High 2 Low Direct Drive via Clutch Drive belt tensioner wheel Blow bar lifting tool supplied Tip Speed range 3645 m/sec (118148 ft./sec) HOPPER/FEEDER: ... Technical Specifiion Impact Crusher

Get Price -

Kolkata Impact Crusher Blow Bars Manufacturers

Manufacturer Of Impact Crusher Blow Bar In India. Manufacturer Of Impact Crusher Blow Bar. Impact Crusher Blow Bar Performance Data. Blow bar crusher at best price in india indiamartet info of suppliers, manufacturers, exporters, traders of blow bar crusher we are making blow bar, jaw plate, liner, impector and all the parts for crushers for their dimensional accuracy, durability and high ...

Get Price -

Crushers

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impact.

Get Price -

Cgm Impact Crusher Blow Bars

Blow Bars Crushers Crusher Mills Cone Crusher Jaw Crusher blow barsimpact crusher blow bars supplier in india. blow bar can deal with all kinds of materials whose compressive resistance is less than is the main spare part of impact crusher main material is high Online Chat Castingfoundry Impact Crusher Blow Bar At Uae

Get Price -

Crusher spare parts Blow bar lifting tool

Crusher spare parts Blow bar lifting tool Our crusher wear part lifting tools are designed with OEM expertise, making them the best choice to remove hammers from your Outotec crushers. Exclusively designed to lift Outotec manufactured wear parts for NP impact crushers. ENMSE ©2021 Outotec Corporation.

Get Price