-

USA

A hotrolling mill for producing sheet metal has a reversing roughing stand having pairs of roughing rolls and a reversing finishing stand adjacent thereto and having pairs of finishing rolls. Each stand is selectively operable alone and both stands are operable in tandem operation. The roughing rolls have diameters larger than the diameters of the finishing rolls and the finishing rolls ...

Get Price -

(PDF) Modelling and control of a hot rolling mill

In this paper, a real appliion of opti mal control of a hot rolling mill is presented. It is used the state space model formulation in the minimization of the strip thickness variations.

Get Price -

Hot and Cold Rolling Explained | Capital Steel Wire

Rolling processes date back to 1779. The first rolling mill was built in Fontley, Hampsire where Henry Cort developed and received patents for his ideas. The two types of temperaturedependent rolling processes are hot rolling and cold rolling, and they each have their own specific use. Hot Rolling

Get Price -

Hot Cold Working and the Rolling Process

Endless Hot Strip Rolling Process . In conventional hot strip production, slabs of thickness of about 250mm are heated in a furnace and are reduced to 30 to 60mm in thickness after passing through the roughing mill, and then further reducing it to within a range of .

Get Price -

Products › Flat › QSP® Quality Strip Production technology ...

Over the last 25 years the thin slab casting and rolling process has been gaining market share in the production of hotrolled strip, progressively eroding the advantages in certain finishedproduct egories that previously had been the exclusive domain of conventional mills.

Get Price -

rolling mills for copper, rolling mills for brass, rolling ...

We have built this mill range for executing two processes successfully like cold rolling process and hot rolling process. This range of rolling mills is superlatively used in copper industry, metal industry and various machine manufacturing industries for metal working, extrusion, machining and forging techniques.

Get Price -

Gerdau hiring Process Engineer (Rolling Mill

Process Engineer (Rolling Mill Hot End)Process Engineer (Rolling Mill Hot End) Gerdau Monroe, MI 6 minutes ago Be among the first 25 applicants

Get Price -

Rolling

Rolling. In metalworking, rolling is a metal forming process in which metal stock is passed through a pair of rolls. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is termed as hot rolling. If the temperature of the metal is ...

Get Price -

Hot Rolling Mills | Fluke Process Instruments

Hot Rolling Mills Use throughprocess temperature monitoring to gain more insight into the reheat process. Achieving and maintaining the correct temperature through the furnace is crucial in ensuring materials like steel slabs and billets have been uniformly heated during the reheat process at hot rolling mills.

Get Price -

Numerical Modelling and Simulation of the Hot Rolling Mill ...

In the design of the rolling mill plants, it is fundamental to study the behaviour of the deformation process to assess the main process variables (such as torque and rolling force) in all operating this paper, a finite element model is developed and the numerical simulations of the plastic deformation process, in the hot rolling mill of AISI 304 stainless steel, are shown.

Get Price -

Hot Strip Mill Process Flow Chart

Jan 15, 2019 · Hot Strip Mill Process Flow Chart pictures in here are posted and uploaded by for your hot strip mill process flow chart images collection. The images that existed in Hot Strip Mill Process Flow Chart are consisting of best images and high setting pictures. 41 Fresh Cold Rolling Mill Process Flow Chart.

Get Price -

Integrated Scheduling of Reheating Furnace and Hot Rolling ...

In the hot rolling mill, a cold slab is reheated in reheating furnace and then rolled into thin coils through hot rolling process. Traditional research on hot rolling mill generally takes the two processes as two separate singleobjective scheduling problems, though they are closely connected and their optimization objectives are conflicting with each other.

Get Price -

The Advantages and Disadvantages of Hot Rolling

Oct 16, 2018 · Hot rolling can improve the processing performance of metals and alloys. That is to say, the coarse grains during foundry are broken, the cracks are healed, the casting defects are reduced or eliminated, and the ascast microstructure is transformed into a deformed structure to improve the processing properties of the alloy.

Get Price -

Hot Rolled Steel Cold Rolled Steel

May 22, 2019 · The whole process starts out like hot rolling to give the initial shape without much resistance. After that, the metal is left to cool at room temperature. The halfproducts are then fed to cold reduction mills. The metal is rolled to the thickness of .3 mm in case of mild steel and ...

Get Price -

Introduction to Seamless Pipe Manufacturing

Jul 24, 2018 · The mandrel mill shell is then reheated in a reheat furnace so that it can complete the final rolling process and gain its final dimensions and microstructural qualities. Upon exit from the reheat furnace, the tube receives a highpressure water descale, removing the iron oxide scale that formed in the reheat furnace.

Get Price -

Rolling Process: Definition, Working, Rolling Mills ...

Rolling is a metal forming process in which the deformation takes place under the appliion of Compressive forces between the rollers. In this article, we are going to discuss a detailed presentation on the Rolling Process with its Principle, Working, Types .

Get Price -

Hot Rolled Steel

Hot rolling is a costeffective process that results in strong and ductile steel that is easy to work with. At McDonald Steel Corporation, our 14" production line is an eleven stand crosscountry bar mill, and our system is one of the only systems in the world that can produce both .

Get Price -

Difference Between Hot Rolling and Cold Rolling(Comparison ...

Hot Rolling. The process of rolling consists of passing the hot ingot through the two rolls, rotating in opposite directions, at a uniform peripheral speed. To confirm the desired thickness of the rolled section, the space between the rolls is adjusted and is always less than the thickness of the ingot being fed.

Get Price -

REHEATING FURNACES IN STEEL PLANTS

Mar 15, 2016 · In steel plants reheating furnaces are used in hot rolling mills to heat the steel stock (Billets, blooms or slabs) to temperatures of around 1200 .

Get Price -

HotRolling

Hotrolling. Two separate rolling mills are employed to process the raw steel blooms into rebars and highquality steel bars to be used in the automotive industry or in machine construction. To this end, the blooms are once again heated up in a pushertype or in a walkingbeam furnace respectively prior to hotrolling into the size requested by ...

Get Price -

How It Works – Precision Thread Rolling | Today's ...

Thread rolling is primarily a cold forming process done at room temperature, but a niche does exist for hot rolling when materials are greater than Rockwell C 45, because die life would be seriously compromised. Like centerless grinding, its sister process, the .

Get Price -

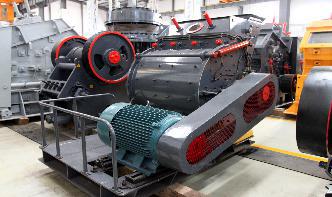

Hot And Cold Rolling Mill Machine | TINVO

Rolling mill is an equipment used for the rolling process of the metal and it can complete the entire process of rolling. There're mainly cold rolling mill, hot rolling mill, continuous casting machine, copper aluminium zinc rolling mill, etc.

Get Price -

Steel Pipe Manufacturing Processes

The continuous mandrel rolling process and the push bench process in the size range from approx. 21 to 178 mm outside diameter. The multistand plug mill (MPM) with controlled (constrained) floating mandrel bar and the plug mill process in the size range from approx. 140 to 406 mm outside diameter.

Get Price -

Aluminium Rolling Lubriion: part 1

View of a typical hot rolling mill showing lubricant appliion. During the hot rolling process, lubriion and thermal control of the work rolls are achieved by spraying oilinwater emulsions onto the rolls in controlled patterns. The emulsion also removes any loose debris from the roll bite area and carries it to the filter where it is ...

Get Price -

Types Of Rolling Process In Manufacturing Industry

The rolling process is done both hot and cold, which is accomplished in rolling mills. A rolling mill is a complex machine having two or more supporting rollers, working rollers, drive motor, roll stands, working rollers, coupling gear, flywheel, etc. According to the requirement of the process and technical issues, these rolling machines are ...

Get Price