-

DFS Refractory Gold Project in Mozambique – AZMET ...

The Refractory Gold Project process flow consisted of two stage crushing and ball milling followed by an ultrafine grind and afloatation circuit for concentration of the gold. Flotation concentrate is oxidised through reactors and processed in a standard gold CIL circuit from where the loaded carbon is harvested and gold recovered through AZMET's Modular Gold Desorption and Recovery Plant.

Get Price -

Gold Recovery And How To Choose The Right Process ...

Ultrafine gold particles can be trapped within the mineral matrix, even at extremely fine grind sizes. Three primary factors cause gold to be considered refractory. Each factor needs to be addressed with a different type of pretreatment before gold can be recovered by conventional cyanidation.

Get Price -

Improvement of Gold Leaching from a Refractory Gold ...

Also, gold is usually disseminated as microfine particles which are easily encapsulated in associated minerals, resulting in unacceptable exposure levels of gold unless undergoing ultrafine grinding with high energy consumption. As a result, proper pretreatments are necessary to improve the leaching of gold from these refractory gold ores [5,6].

Get Price -

The appliion of ultrafine grinding for Sunrise Dam ...

The Anglo Gold Ashanti (AGA) Sunrise Dam Gold Recovery Enhancement Project (REP) was an upgrade project to the existing process plant to increase gold recovery. The project required the existing screened cyclone overflow to be redirected into a new flotation and ultrafine grinding circuit, producing concentrate up to a rate of 400000t/a.

Get Price -

Improving the gold leaching of refractory ores using the ...

· gold recovery of all three refractory gold ores involved in this project. The reactor was also able to reduce the cyanide and oxygen consumption on the Ergo sample. Therefore ... Ultrafine grinding .....18 Mechanochemical activation ...

Get Price -

Upscaling of the RoStar ultra fine grinding mill for ...

process. This is a process developed by MMS for treating refractory gold. Main feature of this process is to grind the gold bearing sulphides preconcentrated by flotation to ultrafine size of minus 10 micron, threat them with oxygen to break up the sulphide surfaces to get better access for cyanide to .

Get Price -

Home

· Albion Process™ has realworld success in delivering consistently high recoveries – up to 97% in refractory gold and over 99% in chalcopyrite copper concentrates. It has much lower capital cost than traditional leaching plants like pressure oxidation (POx) plants and because it operates at atmospheric pressure, it completely avoids the myriad of risks of POx plants.

Get Price -

Heap Biooxidation of Sulfide Concentrates

· With the exception of ultrafine grinding, all processes for pretreating refractory sulfide ores require the oxidation of the sulfide minerals to liberate the gold particles. Pressure oxidation, roasting and biooxidation involve the reaction of molecular oxygen with the sulfide minerals and encounter limitations in transferring sufficient oxygen during the reaction.

Get Price -

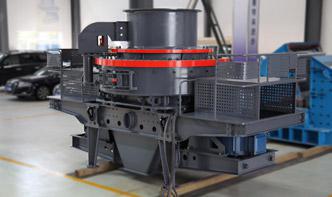

Fine Grinding Refractory Machinery Suppliers Rymond Mill ...

Grinding Mills Ceyssatite. HGM90 ultra fine mill, ultra fine grinding equipment. HGM90 ultra fine mill is the new type ultra fine grinding equipment for making fine and ultra fine powders, which is widely applied in the industries of metallurgy, mining, chemistry, cement, construction, refractory materials, ceramics, andget price

Get Price -

ultrafine grinding ball mill in turkey

ultra fine ball mills from turkey 202098 · Ultra Fine Ball Mills From Turkey,Turkey produces 35 million tonnes of cement annually from more than 100 grinding circuits and the ball mill the perfect mixing model was used as the basic model for the ball mills this model has been lound to bc very successful in wet ball milling used for holding the fine material swept by ...

Get Price -

FLOWSHEET DEVELOPMENT FOR GOLD OREBODIES

REFRACTORY GOLD ORE PROCESSES 'Refractoriness' results in poor gold ... liberated by ultrafine grinding or by oxidizing the sulphides using techniques such as roasting, ... cost of additional processing such as fine grinding or sulphide oxidation is reduced by reducing the mass of material to be treated.

Get Price -

Technology options for processing complex and double ...

· The subsequent Study highlighted how difficult these double refractory gold ores are to process and highlighted some recent technology developments may be applicable. CITATION: Connelly, D, 2018. Technology options for processing complex and double refractory gold ore, in Proceedings Complex Orebodies Conference 2018, p 94 (The Australasian Institute of Mining and Metallurgy: .

Get Price -

Ultra Fine Copper Ore Grinding

The ultra fine grinding mill can grind the ore material to be 220um, is widely used in all kinds ores concentrate regrinding like gold ore, copper ore, silver ore, leadzinc ore and other refractory metallic amp nonmetallic ultrafine grinding, the ore is fully dissociated, which creates good conditions for subsequent .

Get Price -

INVESTIGATION OF THE AMENABILITY OF A COPPERRICH ...

refractory gold ore to cyanide leaching was investigated. The effect of H 2 SO 4 pretreatment for reactive copper removal on the gold extraction in the subsequent cyanide leaching was examined. Effect of cyanide concentration in the range of 18 g/L NaCN was also tested on the cyanide leaching of gold. Ultrafine grinding (UFG) as a

Get Price -

Centerra Gold

The ISA mill was commissioned in October 2005 and provides additional incremental liberation of the fine refractory gold (25 microns) enclosed in pyrite. The flotation tailings with an average grade of gram of gold per tonne are thickened to 50% solids and subjected to cyanidation for ten hours in a CIL circuit similar to the circuit used for the sulphide concentrate.

Get Price -

Extracting gold from pyrite roster cinder by ultrafine ...

· The ultrafinegrinding and resininpulp with pH value of 10 are used to extract gold from pyrite roster cinder. During leaching process, aluminium oxide ball is used as stirring medium, hydrogen peroxide as leaching agent and sodium hexametaphosphate as grinding agent. With AM2σ resin as absorber and sulfocarbamide as eluent, gold is recovered from cyanide pulp of pyrite roster cinder by ...

Get Price -

Silica Gold Fine Powder Ultra Fine Grinding Mill Ultra ...

Silica Gold Fine Powder Ultra Fine Grinding Mill Ultra Fine Ball Mill. China 4 rollers grinding mill for stonepebbleriver sand coal slurry chicken manureindustrial sandcoal gypsum find details about china mining machine grinding mill from 4 rollers grinding mill for stonepebbleriver sand coal slurry chicken manureindustrial sandcoal gypsum henan centbro machinery equipment co ltd.

Get Price -

Gold extraction

Gold extraction refers to the processes required to extract gold from its may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore.. Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of ...

Get Price -

TECHNOLOGY FOR PROCESSING OF REFRACTORY GOLD .

disseminated gold from the flotation concentrate resulted from processing of a refractory ore of one of Russian gold deposits. Concentrate description Gold grade of the head flotation concentrate was g/t. The concentrate size was 80% 80 um. Mineral composition of the concentrate comprises 17% of rockforming minerals, 59% of pyrite and 24%

Get Price -

Extracting gold from pyrite roster cinder by ultrafine ...

· The ultrafinegrinding and resininpulp with pH value of 10 are used to extract gold from pyrite roster cinder. During leaching process, aluminium oxide ball is used as stirring medium, hydrogen peroxide as leaching agent and sodium hexametaphosphate as grinding agent. With AM2σ resin as absorber and sulfocarbamide as eluent, gold is recovered from cyanide pulp of pyrite roster .

Get Price -

Getting a Handle on Refractory Ore May Determine Gold's ...

· A "refractory" gold ore is an ore that has ultrafine gold particles disseminated throughout its gold occluded minerals. These ores are naturally resistant to recovery by standard cyanidation and carbon adsorption processes. A refractory ore generally contains sulphide minerals, organic carbon, or both, generally leading to a more complex ...

Get Price