-

Process for using mill scale in cement clinker production ...

Nov 19, 2002 · This mill scale flakes off the steel as it is being formed and contains chemical elements that are necessary in the art of making cement clinker. The mill scale obtained from carbon and alloy steel casting and rolling mill operations has been shown to contain predominantly various iron oxides, and minor or trace amounts of silicon oxide ...

Get Price -

surplus ball mill for grinding clinker

cement clinker ball mill europe. Cement Clinker Ball Mill Europe haarhautpflegede Cement Clinker Ball Mill Europe Overview The ball mill for clinker is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy chemical electric power ...

Get Price -

China tpd Cement Grinder Mill Clinker Production ...

tpd Cement grinder mill Clinker Production Line, Cement Clinker Grinding Plant for Sale cement clinker grinding plant is suitable for grinding the barite, limestone, kaolnite, ceram and slags, etc. which below scale of Moth and below 6% shadness and 280odd sorts of noninflammable and nonexplosive stuff in the trades of mining, metallurgy, chemical engineering and building ...

Get Price -

Clinker | Amoot Iranian Trading Company

The cement clinker is a dark grey nodular material produced through heating the ground limestone and clay at a temperature range of degrees of centigrade. The produced nodules are ground up to a fine powder to produce cement, with a small amount of gypsum included to control the properties. Nodules consist of a sixe..

Get Price -

Sell Portland cement clinker vertical mill(id:)

Portland cement clinker vertical mill, vertical roller mill sets drying, crushing, Vertical mill, separator, collection and transport together. It has been the first to achieve largescale production. The floor area is smaller; the unit current drain of pulverizing and metal abrasion is lower.

Get Price -

Clinker Cement Plant, Clinker Grinding Plant Manufacturers ...

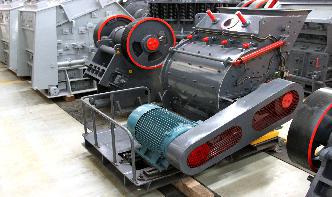

Cement Clinker Grinding Plant. Cement Clinker Grinding Plant is developed with all latest equipments and machines like Precrusher, feed hopper, Table feeders, Ball mill, Blending, Packing Plant with all Material Handling equipments. We manufacture and supply up to 50 TPD to 1000 TPD clinker cement plants on turnkey basis.

Get Price -

Performance Enhancer for Portland Limestone Cement (PLC)

The performance of strength enhancers not only depends on the clinker and cement composition but also on the cement fineness. The influence of fineness on the efficiency of two alkanolamines (A and B) was tested with two different portland cements which were ground in the laboratory ball mill of Sika Technology AG (see Figure 2).

Get Price -

Vertical Cement Mill

2. Reducing the power consumption of cement clinker preparation effectively. According to the display of pulverized coal measured data, it can be saving electricity above 30% use of vertical roller mill production per ton cement clinker than traditional tube mill, and the power saving effect is very remarkable. 3.

Get Price -

Cement Grinding Stage

Clinker, gypsum and admixture – the three components are mixed in a certain specific proportion and transported on the belt conveyor to the cement mill for further grinding. Cement roller press, cement ball mill, cement vertical mill is where the mix is further ground. The cement mill grinds all materials into specific sizes and the particles ...

Get Price -

optimum clinker temperature for cement mill

Cement mill,clinker grinding plant,raw mill for Cement industries... optimal fuel efficiency in the cement ... clinker coolers is comprised of cement minerals and is restored to the operation. based on the cooling efficiency and desired cooled temperature.

Get Price -

clinker grinder ball mill machine for cement production

2,782 cement clinker grinding mill products are offered for sale by suppliers on Alibaba, of which cement making machinery accounts for 13%. A wide variety of cement clinker grinding mill options are available to you, There are 1,183 suppliers who sells cement clinker grinding mill on .

Get Price -

Sustainable Clinker and Cement Production by Using ...

Clinker analysis to check kiln operation and clinker quality and material balances Analysis of finished cement to check mill operation, gypsum and SCM additions as well as the quality of the finished cement (example EN 197, ASTM C150, ASTM C595, and ASTM C1157)

Get Price -

Optimization

CM2 is an open circuit ball mill system. The product from CM1 and CM2 are 4700 and 4100 Blaine respectively. To satisfy the strength requirements of the cement, the cement mill feeds for CM1 and CM2 included 68% and 79% clinker, respectively. The remainder of the mill feed mix include additives such as gypsum, limestone and pozzolan.

Get Price -

SICEMENT Automation | Cement | Siemens Global

Oct 25, 2021 · The Chinese company Sinoma/CBMI was assigned to build a turnkey cement mill with a capacity of 3,600 tons of clinker per day – a significant project in Benin. Siemens supplied all the hardware and software engineering, from the integration of PCS 7 with CEMAT to data archiving and monitoring services.

Get Price -

What Is Cement Clinker And Clinker Grinding Processing

Apr 09, 2021 · The cement clinker material is crushed by the crusher to the fineness (15mm50mm) that can enter the mill. The second stage: milling. The crushed small pieces of cement clinker are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

Get Price -

clinker feed to mill by pendulum

A mathematical model has been developed for an open circuit twocompartment tube mill grinding cement clinker Samples were collected of the feed and product, and inside the mill In the laboratory, sizings were done between the top size and 2 μm, and the breakage distribution function of the clinker was obtained by using a twin pendulum ...

Get Price -

Optimization of Cement Grinding Operation in Ball Mills ...

Clinker, Gypsum and other desired additives are fed to the ball mill in specific proportions based on the quality requirement. Feed material is ground in the ball mill, discharged and fed to a classifier with the help of a bucket elevator for classifiion of the ground cement into two streams – coarse and fines.

Get Price -

Resistance to Grinding and Cement Paste Performance of ...

Apr 19, 2021 · Materials. Interactions between clinker, highgrade limestone and synthetic gypsum during laboratory grinding in a Bond ball mill were studied. The materials were obtained directly from a cement production facility.

Get Price