-

Flotation Reagents' Types and Working Principles | CNFREE

Mar 15, 2019 · Flotation reagents refer to the agent that used in mineral flotation process, which can adjust the flotation behavior of minerals thus achieving a good effect of mineral using flotation reagents is the most flexible, effective, and convenient method of controlling flotation commonly used flotation reagents can be mainly divided into three types according to ...

Get Price -

fluorite cone crusher

Apr 26, 2021 · fluorite Processing. The main component of fluorite is CaF2, which is often used as a source of fluorine in industry. Fluorite ore can be sorted by means of gravity separation and flotation. When the raw ore is coarsegrained fluorite ore, a gravity separation process can be .

Get Price -

Separation of heavy metals: Removal from industrial ...

Jan 01, 1993 · article{osti_, title = {Separation of heavy metals: Removal from industrial wastewaters and contaminated soil}, author = {Peters, R W and Shem, L}, abstractNote = {This paper reviews the applicable separation technologies relating to removal of heavy metals from solution and from soils in order to present the stateoftheart in the field.

Get Price -

sludge filter press with low cost for fluorite ore mining

Fluorite Flotation Process,Fluorite Flotation Separation, Fluorite ore processing methods which is one roughing repeatedly choice,as a collector agent rougher with oleic acid or its substitute The process is simple, lowcost advantages can be selected from the high calcium fluorite ore grade fluorite concentrate with a low content of calcium carbonate

Get Price -

How to Extract Lithium from Its Ore?

Sep 10, 2019 · In industrial production, the process used generally has the following steps: scrubbing, separation, water immersion, carbonization, pyrolysis. It's also a simpler process. In addition to the above three methods, other methods used to extract lithium from salt lake brines have not been used in industrial production, so they will not be ...

Get Price -

China Fluorite Ore Processing Line 200tpd Fluorite Mineral ...

According to the differences of physical and chemical properties of Fluorite ore surface, Fluorite ore flotation production line is treated by flotation reagents, the siliver deposits are selectively stick to the bubbles for the purpose of separation. Fluorite flotation process is divided into several parts, such as crushing, grinding and ...

Get Price -

Fluorite Flotation Process,Fluorite Flotation Separation,

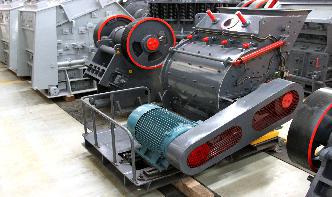

It is used in fluorite coarse crushing process. Cone crusher is the fine crushing machine used in fluorite processing plant. After fluorite crushing process, fluorite is less than 15mm. Grinding mill used Ford fluorite processing. Ball mill is the most commonly used fluorite ore dressing machinery. After grinding, fluorite is less than

Get Price -

flotation fluorite ores

Feb 15, 2020 · Fluorite is an important strategic mineral. In general, fluorite ores will contain a certain amount of calcite gangue mineral. Thus, they need to be separated from each other. For an economic separation, a reverse flotation process is used to float calcite gangue from fluorite. However, little information on the separation is available.

Get Price -

Summary of Fluorite Ore Flotation Process

Apr 24, 2019 · Quartz type fluorite ore. The separation of quartz and fluorite achieved by grinding, it is an important factor affecting the flotation of quartztype fluorite. The ground ore of a coarse size indies that may have many associated fluorite ore lumps, these lumps may increase the silica content, decrease the flotation effect.

Get Price -

Fluorite Flotation Process

Fluorite flotation process is applied for refractory fluorite with complied properties such as high mud content, impurity containing, fine particle distribution etc. Our fluorite flotation process has many advantages including automatic controlling, high efficiency, safety, fast and low energy consumption.

Get Price -

How to Separate Gold From Sand?

Dec 19, 2019 · The process of separating gold from sand mainly consists of four steps: crushing and screening, remove slime from gold sand, separation, thickening and dewatering stage. 1. Crush and Screen the Sand. Most of the alluvial gold contain cemented mud, which is attached to the gravel or pebbles. If it is not broken in advance, it will cause gold ...

Get Price -

JPA

PROBLEM TO BE SOLVED: To provide a novel purifiion method of fluorite, particularly a purifiion method whereby the arsenic content in the fluorite can be effectively reduced. SOLUTION: The purifiion method of fluorite comprises a step of pulverizing raw material fluorite containing CaF

Get Price2 so as to obtain ultrafine fluorite particles with an average particle size of ≤10 μm ... -

Fluorite stone crushing processing plant in South Africa

Fluorite, also known as fluorspar, is a major source of industrial fluoride is one of the important nonmetallic mineral raw materials. Fluorite is widely used in the metallurgy of aluminum, glass, ceramic, cement chemical industry. ... jig in gravity separation, to obtain two grain size grade fluorite mine. ... After crushing ...

Get Price -

Relevant Problems of Quartz Extraction Technology

Jun 21, 2019 · In the quartz sand extraction process, because there are fewer impurities in the raw ore, the main beneficiation process is to purify and remove a small amount of impurities in quartz sand. Currently, the processes used include: classifiion and desliming, scrubbing, magnetic separation, flotation, acid leaching and so on.

Get Price -

The process of separation and flotation of metal dressing

The process of separation and flotation of metal dressing. Home; The process of separation and flotation of metal dressing; Mineral processing Wikipedia 10 may 2017 ... Process methods of fluorite ore are gravity separation and flotation. ... Fluorite Flotation Process is applied for refractory ... some multivalent metal ions ...

Get Price -

The Improvement Effect of Dispersant in Fluorite Flotation ...

Mar 25, 2015 · Abstract. Different dispersants were added in the dispersion process to improve the efficiency of fluorite flotation. The types and dosage of dispersant on the improvement of fluorite flotation were investigated; when the sodium polyacrylate (SPA) was used as the dispersant and its addition is %, the concentrate grade of CaF 2 increased from 90% to 98% and the fluorite .

Get Price -

Used Dewatering Equipment • Langley Separation and Process

Used Equipment for Sale. Check this page frequently for all types of used dewatering equipment that we have available for sale. This list changes often, as we acquire and sell various equipment, but we specialize in the following types of used equipment. Now Available – Trailer mounted 300GPM Bargam centrifuge system.

Get Price -

Industrial gases | MAN Energy Solutions

The energy required for industrial gas processes is considerable. Highly efficient compressors from MAN Energy Solutions support you in cutting costs and greenhouse gas emissions. We supply compressors for air, dry air, nitrogen and oxygen for your air separation trains. We have a long history of developing and supplying some of the most ...

Get Price -

Fluorite Washing Machine In Mongolia

Fluorite Washing Machine In Mongolia, Find Complete Details about Fluorite Washing Machine In Mongolia,Fluorite Washing Machine,Fluorite Machine,Fluorite Machine from Mineral Separator Supplier or ManufacturerGongyi Forui Machinery Factory

Get Price