-

Line Diagram Of Coal Milling In Thermal Power Plant

A new modelbased approach for power plant Tubeball mill ... Jan 25, 2014 ... A novel online model based power plant condition monitoring method is reported. .... The air flow system of a Tubeball mill can be described by the diagram in Fig. .... Thermal process analysis ... The startup sequence for a typical coal milling process can be ...

Get Price -

Power Plant Services –

. Power Plant Services has extensive, proven parts manufacturing capabilities for the Power Generation industry as well as Pulp Paper, Refineries and Steel Mill industries. PPS employees have a wide scope of knowledge in power generation parts manufacturing and are continually developing expertise in different industries ...

Get Price -

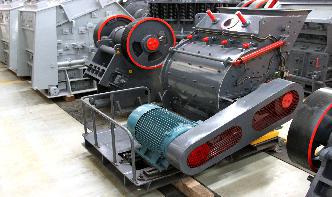

Types Of Rolling Process In Manufacturing Industry

Rolling is the most important and widely used metal forming process because of its lower cost and higher productivity. The rolling process is best defined as the shaping of metals into semifinished or finished forms by passing between rollers rotating in opposite direction.

Get Price -

Bagasse Power |

· Sugar makers have a sweet power advantage. When burned by a sugar mill, bagasse, the fibrous material leftover after juice is extracted from sugarcane, usually produces enough electricity to power all of the mill's operations and then some. For every 10 metric tons of sugarcane crushed, a sugar factory produces nearly 3 metric tons of wet ...

Get Price -

Pe250*400 Working Of A Ball Mill Video | Crusher Mills ...

vedio for working of ball mill used in thermal power plant. Posted at: January 12, 2013 [ . calculation of percentage volume of gringing media in ball mill; video . MTW Series of Trapezium Mill, Milling Machine, Raymond Mill . Working Principle: MTW series mill system adopts vertical structure; . PE250×400: PE250×400: PE250×750: Motor: . Ball Mill; Contact us. Nicaragua Silie ...

Get Price -

McCoy Machine Tools Pvt. Ltd.

McCoy Machine Tools Pvt. Ltd. | | info | | Spare Manufacturer for Cement Industry, Spare Manufacturer for Thermal Power Plant, Furnaces, Precision Machining Products, Oil and Natural Gas Components, Various Fabriion Items, Rotary Screen Separator, Spare Manufacturer for Gravimetric Coal .

Get Price -

SKF Group homepage | SKF

SKF Kenya reloes to focus on core competencies and expand the distributor network to boost customer service. SKF Kenya Ltd. recently reloed to new premises in a bid to increase efficiency, pass better value on to SKF Authorised Distributors and improve its .

Get Price -

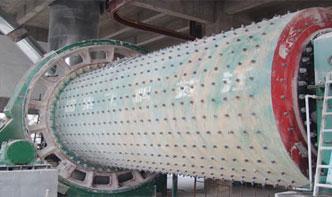

Ball Mill: Operating principles, components, Uses ...

· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size.

Get Price -

Back to Basics Hammer Milling and Jet Milling Fundamentals

mer mill operation but not for jet mills. Melting point and thermal instability. Jet mills can grind materials with low melting points effectively because these mills have intrinsic cooling due to compressed air expansion in the body of the mill. With the help of sweeping air, hammer mills may also be able to process materials with low

Get Price -

Pulverized Coal Preparation Production Line_ZK Ball Mill ...

Main bearing pedestal of ball mill adopts water circulation device to reduce the working temperature of bearing. This solution can prevent the shorten of lifetime for bearing which is caused by high temperature of material. 2. Lubriion for main bearing bush adopts hydraulic oil station. This solution can increase lifetime of alloy bushing and reduce the resistance during the operation of ...

Get Price -

Ball Mill|Coal Milling Plant Of Thermal Plant

Coal Milling In Thermal Power Plant Ball Coal Mill Vibration. Coal hangup in bowl mill operations bright hub engineering coal mill construction and its part in thermal power station glenbrook steel mill at waiuku and the thermal power station bought in 1919 parts of thermal power plant coal handling plant wagon trippler conveyor belt mill. Get Price . Coal Mill In Thermal Power Plant ...

Get Price -

Ball Mill Design/Power Calculation

· Ball Mill Power Calculation Example #1. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns). The required product size distribution is to be 80% passing 100 mesh (149 microns). In order to determine the power requirement, the steps ...

Get Price -

Milling Process In Thermal Power Plant

· ball mill in coal based thermal power plant. Coal Milling In Thermal Power Plant Kirsten s Crew. Coal mill used in thermal power plant aluneth mining why is a bowl coal mill used in a thermal power plant jun bowl mills are one type of grinding mill used in a coalfired thermal power plant raw coal fed into the mills gets converted into pulverised coal and carried to the burners by primary air ...

Get Price -

thermal power plant milling

China coal millThermal Power Plant products offered by Xinxiang Great Wall Machinery Co.,Ltd, find more coal millThermal Power Plant suppliers manufacturers on 24*7 support Online Solution . Grinding mill has b. Read More; New and Second Hand Coal Mill. Coal mill, which is also known as coal grinding mill or coal milling ...

Get Price -

General Catalogue

Deep groove ball bearings Angular contact ball bearings Selfaligning ball bearings ... Power footpound per 1 W 0,7376 ft lbf/s 1 ft lbf/s 1,3558 W second ... plete manufacturing plant – from bearing selection and calculation, to installation, monitoring, ...

Get Price -

China Ball Milling Machine, Ball Milling Machine ...

China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: milling machine, ball mill, ball mill machine. Here we are going to show you some of the process equipments ...

Get Price -

Ball Mill Working Principle And Main Parts

Ball Mill. SBM ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefiion, electricity, cement and chemical new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale production.

Get Price -

ball mill for thermal power plant

ball mill coal burning power plant Ore plant,Benefiion Machine Manufacturer and supply. ball mill coal burning power plant COAL BASED THERMAL POWER PLANTS: COAL MILLS FOR Dec 13, 2011 · This website will provide the most useful technical information about COAL BASED THERMAL POWER STATIONS particularly for power

Get Price -

Mill Speed

· Dipak K. Sarkar, in Thermal Power Plant, 2015 Lowspeed mill. Mills operating below 75 rpm are known as lowspeed units include ball or tube or drum mills, which normally rotate at about 15–25 types of mills,, ballandrace and rollandrace mills, that generally fall into the mediumspeed egory may also be included in this egory provided their ...

Get Price -

Custom Engineered Equipment

Since 1951, we've been providing the fertilizer industry with custom... In addition to our individual equipment lines, we do offer complete... All FEECO equipment and process systems can be outfitted with... We work with everyone from process startups and entrepreneurs, all the way to Fortune 100 companies across a variety of industries.

Get Price -

How ball bearing is made

Balls. 4 The balls are a little more difficult to make, even though their shape is very simple. Surprisingly, the balls start out as thick wire. This wire is fed from a roll into a machine that cuts off a short piece, and then smashes both ends in toward the middle. This process is called cold heading.

Get Price