-

Insight into the effect of maleic acid on the preparation ...

The control of crystal morphology is crucial to preparation of αhemihydrate gypsum (αHH). αHH was prepared from phosphogypsum (PG) in Na 2 SO 4 solution at different temperatures. The effect of maleic acid (C 4 H 4 O 4 ) on the dehydration rate and growth behavior of αHH was investigated by Xray diffraction (XRD) and scanning electron microscope (SEM), and the interactions of C4 ...

Get Price -

Detection and Determination of Gypsum in Soils ...

The unsaturation is determined by electrical conductivity (EC) measurements before and after saturating the extract with reagent CaSO 4 ·2H 2 O. Increasing the water content of the soil in preparation of the dilute soil extract causes an exchange of adsorbed ions for Ca 2+ from gypsum, and the formation of an equivalent amount of sulfate ...

Get Price -

Alginate

Above the margin of the preparation. Undercuts. Apical to the margin of the preparation. Alginate. Elastic, irreversible hydrocolloid impression material. Requisites of impression material. Accuracy of copying ... Type V gypsum with water powder ratio of and setting expansion of %. Used for dies and working casts for high fusion alloys ...

Get Price -

In the preparation of gypsum products, an increase in the ...

In the preparation of gypsum products, an increase in the water/powder ratio will accelerate the setting reaction. increase the compressive strength. increase the surface hardness. None of the above. 0 explanations. Explanations are useful to guide through learning process and confirm that the correct answer is indeed correct.

Get Price -

FGD Gypsum Production Process – Gypsum Association

FGD Gypsum Production Process. Mineralogically identical to natural gypsum, FGD gypsum, or synthetic gypsum, is produced from gas captured within emission control systems at coal fired electric utilities. An emission that would compromise air quality, sulfur dioxide (SO 2) gas, is the primary contribution coal makes to FGD gypsum.

Get Price -

Effect of pH on the Preparation of {alpha}Calcium Sulfate ...

Dec 15, 2009 · article{osti_, title = {Effect of potassium sodium tartrate and sodium citrate on the preparation of {alpha}calcium sulfate hemihydrate from flue gas desulfurization gypsum in a concentrated electrolyte solution}, author = {Shen, Z X and Guan, B H and Fu, H L and Yang, L C}, abstractNote = {Flue gas desulfurization (FGD) gypsum mainly composed of calcium sulfate .

Get Price -

Preparation of pure calcium carbonate by mineral ...

Mineral carbonation is one of the geological approaches for the sequestration of anthropogenic CO2 gas. Its concept is based on the natural weathering processes in which silie minerals containing divalent ions such as Ca or Mg are carbonated to CaCO3 or MgCO3 in the reaction with CO2gas. Raw materials for the mineral carbonation have been extended to various industrial solid wastes such ...

Get Price -

Preparation of Multifunctional βhemihydrate Gypsum using ...

Jan 06, 2021 · But in general, the composite addition of OSP and Ag/TiO 2 particle increase the compressive and flexural strengths of gypsum plasters at 1, 3, and 28 days. These results provide theoretical guidance for the recycling of OSP and the preparation of gypsumbased products with antibacterial and formaldehyde degradation capabilities.

Get Price -

Transformation of flue gas desulfurization (FGD) gypsum to ...

2 days ago · A novel way for transformation of flue gas desulfurization (FGD) gypsum, an industrial byproduct to βCaSO 4 · 2 O whiskers is investigated for calcium sulfate rich alternative construction material. As the consumption of gypsum products is increasing in construction industry and limited amount of natural gypsum is available, herein facile water treatment is used to generate fine ...

Get Price -

Setting time of construction gypsum, dental plaster, and ...

Sep 21, 2020 · Introduction. Gypsum is one of the natural minerals that contain calcium, hydrogen, water, and sulfur, known as calcium sulfate dihydrate (CaSO 2 O). 1 Gypsum products are available in the form of a fine white powder which has undergone calcination or heating at a temperature of 110‒130°C in the open air. This process causes some of the gypsum material to become .

Get Price -

What will happen if heating is not controlled while ...

What will happen if heating is not controlled while preparing Plaster of Paris from gypsum? 19/6/2014 2 Comments It may be noted that the temperature should be controlled carefully. It should not be allowed to rise above 152°C (425K) because, if whole of the water is lost then anhydrous calcium sulphate is produced, which is called dead burnt ...

Get Price -

Gypsum: an old product with a new use | Integrated Crop ...

Gypsum is a fertilizer product and supplies the cropavailable form of calcium (Ca 2 +) and sulfur (SO 4 2). If these forms are deficient in soil, then crop productivity will benefit if gypsum is applied. This is a big "if" for Iowa soils. Research has not shown deficiency of Ca and normally any potential problem with low Ca levels is taken ...

Get Price -

Publiions – English

Recommended Specifiion for Preparation of Gypsum Board Surfaces Prior to Texture Appliion » KiB 4,743 hits September 30, 2009 The purpose of this document is to describe guidelines for preparation of gypsum board surfaces prior to texture appliion. Method for Inspecting Interior Joint Treated Gypsum Panel Surfaces

Get Price -

GypsumDL: an opensource program for preparing small ...

May 24, 2019 · In mpi mode, GypsumDL distributes smallmolecule preparation across multiple computers. Its static loadbalancing approach splits the array of input small molecules into chunks that can each be handled concurrently on a different computer (, node).

Get Price -

Gypsum Plaster : Advantages and Disadvantages

Gypsum Plaster (POP) bags has to be stored on elevated surface (dry platform) made of bricks/timber/concrete at site. The minimum shelf life of Gypsum Plaster 34 months from the date of manufacture. But if properly stored gypsum can be use in excessive of .

Get Price -

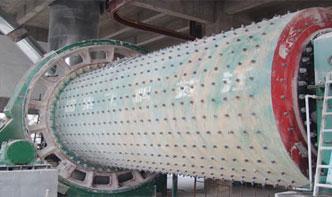

Lab Scale Preparation of Gypsum Wallboard

Gypsum manufacturing process consists of three main steps (1) rock preparation, (2) calcining and (3) formulating and manufacturing. Though we start with buying the gypsum material from one of the providers so the next important step ahead is the calcination process.

Get Price -

LaboratoryScale Studies on Smart Gypsum Composite Boards ...

Mar 03, 2016 · An experimental study is presented examining the preparation and characterization of a smart gypsum composite board for thermal comfort building appliion. Composite boards were prepared by mixing 1–30% by weight nanoencapsulated n octadecane phase change material (PCM) with gypsum to develop gypsumbased building materials with thermal ...

Get Price -

Preparation of nanogypsum from anhydrite nanoparticles ...

Sep 23, 2006 · The preparation of calcium sulfate by flame synthesis resulted in the continuous production of anhydrite nanoparticles of 20–50 nm size. After compaction and hardening by the addition of water, the anhydrite nanoparticles reacted to nanogypsum which was confirmed by Xray diffraction, diffuse reflectance IR spectroscopy and thermal analysis.

Get Price -

Gypsum products

Jun 21, 2018 · 10. SETTING OF GYPSUM PRODUCTS The reaction between gypsum products and water produces solid gypsum, and the heat evolved in the exothermic reaction is equivalent to the heat used originally for calcination. Set gypsum products probably never attain conversion unless they are exposed to high humidity for a long time.

Get Price -

Mortar: Classifiion, Properties, Preparation and Uses ...

(v) Gypsum mortar. (i) Lime Mortar: In this type of mortar, the lime is used as binding material. The lime may be fat lime or hydraulic lime. The fat lime shrinks to a great extent and hence it requires about 2 to 3 times its volume of sand. The lime should be slaked before use. This mortar is unsuitable for waterlogged areas or in damp ...

Get Price