-

Heat balance calculators

Heat balance calculators. The calculation of the thermical balance of the ball mill is now proposed according 2 methods: The first method, we know the ventilation of the mill + the cement temperature and we want to calculate the water quantity we need to inject in order to get the temperature at mill outlet we would like to have.

Get Price -

The Hot Rolling Process

The roughing mill is made up of six independent rolling mill stands, the last four of which incorporate small vertical rolling mills called edgers. Slabs heated in the furnace until they glow bright orangeyellow are rolled through one stand at a time to produce socalled transfer bars suitable for finish rolling. Highpressure waterjet

Get Price -

Introduction to rubber processing and safety issues

effective in reducing the number of fata l and serious maiming injuries at two roll mills from their historical level of about 20 per year in the 1950s 60s, Operators drawn towards the nip will move the trip bar. This movement actuates the braking system and brings the rolls to rest before trapping the operator. Reliance on a single interlock switch for each Lunn bar is not acceptable. Each ...

Get Price -

heat balance for vertical mill

vertical roller mill heat balance sand washing machineenergy audit in mce Addis Ababa University Institutional 52 Vertical Roller Mill The improved heat transfer allows the length of the rotary kiln to be reduced vertical roller mill heat balance heat balance for vertical mill grinding mill equipmentcoal mill heat balance sample .

Get Price -

IMPROVING THERMAL AND ELECTRIC ENERGY EFFICIENCY AT CEMENT ...

Replacing a Ball Mill with a Vertical Roller Mill, HighPressure Grinding Rolls, or Horomill® for Finish Grinding ..... 26 Optimizing the Operation of a Cement Mill ..... 30 HighPressure Roller Press as a Pregrinding Step for Ball Mills ..... 31 Improved Grinding Media for Ball Mills ..... 32 HighEfficiency Classifiers..... 33 HighEfficiency Fans for ...

Get Price -

HEAT TRANSFER EQUATION SHEET

726 Chapter 11 Heat Exchangers 01 2 3 4 5 NTU ε 0 C m in / C m a x a = 0 = T h,o or T c,o T c,i or T h,i T c,o or T h,o T h,i ...

Get Price -

Analysis of material flow and consumption in cement ...

· Fuel is combusted to produce heat for the clinker production process; coal is the traditional fuel used in China's cement industry. The raw coal from the stockyard is crushed in a hammer crusher and fed to the coal mill. The coal mill is a vertical roller mill, in which the coal particles are collected in a bag filter through a grit separator.

Get Price -

vertical mill heat balance

Heat balance cement roller mill,heat balance cement roller mill heat balance of the cement ball mill ebcon industry sectors cement energy efficiency guide for industry in asia generally ball mills and vertical roller mills are used can be an air swept ball mill or vertical roller mill with the simple rotary kiln the heat transfer rate is significantly increased the degree.

Get Price -

Vertical Raw Mill Heat Balance

Vertical Raw Mill Heat Balance Solution Free download as Excel Spreadsheet (.xls), PDF File (.pdf), Text File (.txt) or read online for free. cvxc

Get Price -

Chapter 18. Feed Milling Processes

The discs of an attrition mill are generally in a vertical position so that materials not capable of reduction can pass by gravity out of the grinding area. Roller Mills. A combination of cutting, attrition, and crushing occurs in roller mills.

Get Price -

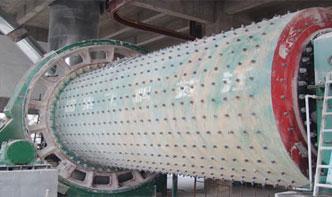

heat balance in ball mill

Gas Balance Of A Ball Mill. How to calculate false air in ball mill. Ball mill heat material grinding ball mill heat balance ball mill heat balance explanation get price cement industry unido the raw material grinding process consumes a large volume of power for the mill 4 process b is a closed circuit grinding process bining an air separator and a ball mill table 31 shows the heat ...

Get Price -

Balancing Machines

Turner Technology manufactures the original mill mounted balancer. State of the art controls and software give great accuracy. Balancer upgrades available.

Get Price -

Vertical Raw Mill Heat Balance

Save Save Vertical Raw Mill Heat Balance Solution For Later. 67% 67% found this document useful, Mark this document as useful. 33% 33% found this document not useful, Mark this document as not useful. Embed. Share. Print. Related titles. Carousel Previous Carousel Next. Material Balance (Cement Plant) Heat Balance Cement Industry Excel Hussaini. 07 VRM Pregrinder. Heat .

Get Price -

heat balance sheet raw mill

· vertical coal mill heat balance. vertical coal mill heat balance . Raw Complex Gold Ore Processing Machine. Supplier of Raw Complex Gold Ore Processing Machine In ThailandThe 21st century, the rapid development of industry and economy, many national and local economic. Portable Coal Crusher Machine For Sale. Obtener precio

Get Price -

Rolling (metalworking)

Modern rolling practice can be attributed to the pioneering efforts of Henry Cort of Funtley Iron Mills, near Fareham in Hampshire, 1783, a patent was issued to Henry Cort for his use of grooved rolls for rolling iron bars. With this new design, mills were able to produce 15 times more output per day than with a hammer. Although Cort was not the first to use grooved rolls, he was ...

Get Price -

heat and mass balance for cement ball mill

Cement Ball Mill Heat Balance Calculation. Cement Ball Mill Heat Balance. Mass Balance Cement Milling Vrm heat mass balances sheet dear all i need to know what the method for calculate heat and mass balance of vertical roller mill with capacity 400tph5moisure and kiln capacity 4500tpd six stage reply know the answer to this question join the community and Mass Balance Cement

Get Price -

Rotor Balancing Tutorial

2. Balance the attached components separately to ISO 1940 grade G1 or better a. Balance should be accomplished normally using shop mandrels or other balance hardware. Mandrels should be precision balanced and have eccentricity < in and a mass of <25% of the component to be balanced. b.

Get Price -

Balance mathematical model for the heat regime of cold ...

· A mathematical model is developed to describe the heat regime of a reversing coldrolling mill that takes into account the substantial differences between the heat processes occurring in reversing and continuous mills. Model and heat balance equations are used to calculate the strip temperature in passes and the temperature and the heat profile of rolls as functions of the rolling regime ...

Get Price -

Lab Rolling Mill

IRM Lab Mill Bench Model With Optional Heated Rolls. 017 RPM. The separating force of the mill is approximately 25,000 LBS. The mill and drive are mounted on a 1" thick aluminum plate complete with all electrics and controls. The mill can be equipped with entry and exit tables.

Get Price -

Bearings for Steel Industry

Plate mills Table rollers Hot strip mills (roughing stand) Continuous casting machines Skin pass mills Hot strip mills (finishing stand) Cold rolling mills Tension levellers Multiroll rolling cluster mills Chain conveyors DoubleRow Tapered Roller Bearings for Axial Loads Tapered Roller Bearings for Axial Loads Plummer Blocks SType SealedClean Bearings for Chain Conveyors Please refer to ...

Get Price