-

Nature Of Hammer Milling Machine

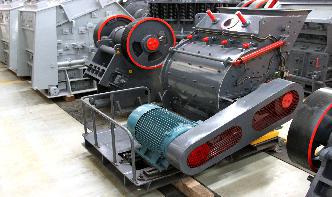

A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little machines have numerous industrial appliions, including: Ethanol plants (grains); A farm machine, which mills grain into coarse flour to be fed to livestock; Fluff pulp defiberizing; Fruit juice production; Grinding used shipping pallets for mulch

Get Price -

Hippo Mills

Milling the World's Grains, Seeds, Legumes, Herbs and Spices. The equipment supplied under the Hippo Mills program includes the ever popular range of Hippo hammer mills (unique and manufactured since 1928), the increasingly sought after Universal Mill (a single mill with plate, stone, hammer and pin mill attachments), the UMS range of stone mills with Danish Engsko stones since 1885).

Get Price -

Hammer Mill | MultimpactMax AUBI |

New standard for hammer mill safety. Zeromotion monitor for motor/rotor standstill, heavyduty trapped key door lock system, door proximity sensor, vibration sensor, all new safety guards set a new standard for hammer mill safety.

Get Price -

Patented Custom Bullets | Hammer Bullets

Hammer Bullets are available for both target shooting and hunting appliions. We can quickly produce virtually any custom caliber and grain your rifle can support. The hollow point design, intended for biggame hunting appliion, initiates expansion upon impact, shedding petals immediately, with the remainder of the bullet staying intact with a blunt front for optimal wound channel.

Get Price -

Roller versus hammer: Corn particle size impacts ...

· Roller mills are the most common mill used in the Corn Belt. They are more energy efficient and generally result in a more uniform particle size than hammer mills. However, hammer mills are still in use, and preferred when the feed will be pelleted or a need for greater flexibility in particle size.

Get Price -

New Holland Hammermill Manual

[PDF] 2018 Kawasaki Meanstreak Owners Cedar rapids 3033 hammer mill manualcedarapids 3033 hammermill, on stand w/baghouse used, pulverizers, rotary screen, jaw; distributor hammermill, cedar rapids, (new holland 10 hammer mill parts manual [PDF] Audi A6 Manual 2017

Get Price -

RENN Hammer Mills – Renn

· RENN Hammer Mills Why Choose a RENN Hammer Mill Dairy and commercial livestock operations that require a very fine grind (finer than 1,200 microns) and need to process large volumes of highmoisture grain should look no further than the RENN 22" diameter, full circle Hammer Mill .

Get Price -

Hammer mills: hammermills

Optimal hammer design and placement will provide maximum contact with the feed ingredient. Hammer mills in which the rotor speed is approximately 1,800 rpm, should be using hammers which are around 25cm (~ 10 inches) long, (~ inches) wide, and ( inches) thick. For a rotor speed of about 3,600 rpm, hammers should be 15 to 20 ...

Get Price -

Controlling the explosion risks within hammer mills

· Feb. 15, 2013. 2,589 views. Grain and feed processed within hammer mills is common fuel for dust explosions due to the nature of its handling and storage. Any time that feed such as grain, meals and flours is handled or moved, the fine organic dusts are at risk of burning and exploding. Milling and Grain magazine.

Get Price -

Used Hammer Mills

HP FITZPATRICK Fitz Mill Comminutor Hammer Mill. 10 HP Shredder SHRED PAX Model AZ7 with Drive Base, Infeed Chute, Motor. 10 HP Densifier PolyMax 2500 with a 15 HP Grinder PolyHog 450. 10 HP Jaw Crusher Whitelaw Model 5 x 12. 20 HP .

Get Price -

Hammer mill: parameters that affects grinding

· Adequate selection of the operating parameters for a hammer mill can maximize efficiency and enhance the uniformness of the product obtained: Material to be ground: when milled, raw materials behave differently; the factors that have the greatest impact on milling properties are firmness and increase of moisture in the product affects these two parameters and raises them.

Get Price -

Back to Basics Hammer Milling and Jet Milling Fundamentals

is frequently used to specify hardness. A hammer mill is typically good for grinding softer materials with Mohs hardness ranging from 1 to 5, while a jet mill can grind materials with Mohs hardness as high as 10. High hardness materials become very abrasive; therefore, they .

Get Price -

Grain Augers | TeleSwing | Grain Cleaners | Roller Mills ...

grain cleaners, roller mill and hammer mill ISO 9001:2015 CERTIFIED FARM KING GRAIN HANDLING EQUIPMENT IS BACKED BY DECADES OF QUALITY BUILT PRODUCTS FOR JUST ABOUT EVERY AGRICULTURAL APPLICATION. Moving grain and commodities has never been easier than with the full line of Farm King grain augers, unloading augers and grain cleaners.

Get Price -

VERTICAL HAMMER MILL

VERTICAL HAMMER MILL HG11 HG22 HG range of vertical (hammer) mills. Our 11 22kw vertical hammer mills are ideal for grinding grains, wood waste etc. for processing prior to pelletizing. Units come with screen options and product removal option (air removal or bottom discharge). Advantages: ‐ efficient and reliable ‐ minimal maintenance

Get Price -

Hammer mills

Hammer Mill From dry saw dust to powder Up to 32 t/h High capacity Low energy consumption Direct or indirect coupling Bidirectional rotor The robust design of PromillStolz hammer mills allows to reach high level of quality and output, for a large range of appliions. Parts and materials are chosen to fulfill specific needs, in order to optimize their lifetime (hammers, screens, body.).

Get Price -

The Philippine Flour Milling Industry

asian grain, inc 4. new hope flour milling corp. 5. great earth industrial food, inc 6. north star flour mill 7. mabuhay interflour mill 8. agripacific corp. (rebisco) 9. bigc agri miller 10. california flour mill group philippine flour millers/manufacturers industry players.

Get Price -

The impacts of hammermill screen size and grain particle ...

However, hammermill screen size did not influence weight gain or FCR. The screen size generated significantly higher starch and protein (N) digestibility coefficients in the distal jejunum and distal ileum than the hammermill screen. 5.

Get Price -

MH57

MH57 HAMMER MILL Unique design construction built to last for industrial and farm use for processing cereal grains as well as for recycling. DIRECTLY INTAKE The HIPPO Hammer Mills are based on cast iron milling plates and a bolt together construction which gives the mill an exceptionally long life span, and makes replacing of parts easy and ...

Get Price -

SKIOLD HAMMER MILL

SKIOLD HAMMER MILL FOR LIQUID GRINDING CAPACITY Plate screen Maize Guiding cap. kg/h Measured in moist maize grain, max. kg/h at motor sizes 11 15 kW. The capacity varies depending on screen size, motor size, moisture contents and sort of grain DM6WM Peripheral inlet DM6WM Center inlet SKIOLD Hammer Mill for Liquid ...

Get Price -

Cage Mills Hammer Mills for Distilleries | Stedman ...

In a hammer mill, rectangular pieces of hardened steel are attached to a shaft and rotate at high speed inside the milling chamber. The grain then encounters a changeable screen with a "close tolerance" gap between it and the rotating hammers. Finally, the grain passes through a screen before exiting the mill. Hammer configuration, rotation ...

Get Price -

INFLUENCE OF SCREEN MESH SIZE OF HAMMER MILL AT .

1 Plant Archives Vol. 19, Supplement 2, 2019 pp. eISSN: (online), ISSN: INFLUENCE OF SCREEN MESH SIZE OF HAMMER MILL AT DIFFERENT WHEAT MOISTURE Jawad Kadhim AL Aridhee 1, Ahmed Merza Abood 1, Flaieh Hammed Kassar 1, Grzegorz Łysiak 2 and Majid Mayih Dakhil 3 1College of Agriculture, AlMuthanna University, Iraq 2University of Life .

Get Price -

DESIGN, FABRICATION AND TESTING OF A LABORATORY SIZE ...

SIZE HAMMER MILL AJAKA and ADESINA A. Department of Mining Engineering School of Engineering and Engineering Technology The Federal University of Technology, Akure, Nigeria ABSTRACT: The laboratory size hammer mill was fabried from locally available materials

Get Price