-

Minimization of variation in clinker quality

Raw Mill Process Raw mill is used for grinding and drying of raw material. It contains rotating table on which four rollers are pressed by hydraulic pressure with a certain clearance required for grinding. The ground product is called raw meal. The purpose of this equipment is drying and grinding of cement raw material. Material is transported ...

Get Price -

The Cement Plant Operations Handbook

mentioned in Chapter 3 for dry raw milling – ball mills, vertical roller mills, roll presses, Horomill – in combination with separators and other optional ancillaries. The finished product is collected by filters for transport to storage, prior to dispatch. Storage of clinker and other components

Get Price -

Stage 4: Finish Process | Cement Production

Roller mills. These have been used for many years for the less exacting rawmilling process, but recently roller mills, ... High pressure roll presses. These consist of a pair of rollers set 830 mm apart and counterrotating with surface speed around –

Get Price -

Screw Presses

The Florapower universal oil press is a robust and easycare machine, the right solution for most oilseeds. It has: a dosing preheating, narrowing screw segments, stepless adjustable pressing gap, stainless steel funnel, special bearing for design for reverse drive, and much more. It is possible to process a wide variety of seeds and raw materials.

Get Price -

Cement Manufacturing Process | Phases | Flow Chart ...

· For example shale, fly ash, mill scale and bauxite. These raw materials are directly brought from other sources because of small requirements. Before transportation of raw materials to the cement plant, large size rocks are crushed into smaller size rocks with the help of crusher at quarry. Crusher reduces the size of large rocks to the size of gravels. Cement Manufacturing Process Phase II ...

Get Price -

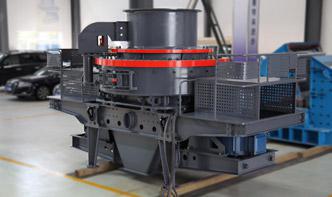

Roller Presses

The KHD Humboldt Wedag Roller Press is available in eight standard sizes ranging in grinding force from 2 to 20 meganewtons. KHD Roller Presses offer a reliable solution for every appliion for grinding cement, slag, raw material or for special appliions, such as preparation of ore.

Get Price -

Rolling Process: Working, Appliion, Defects, Type of ...

Rolling is defined as a process to form metals where the metal strip is pressed by two or multiple rollers, thus the uniform thickness is formed. To do this, the temperature is essential. There are two types of processes. One is Hot rolled and another is Cold Rolled. If the strip is rolled after heating the strip above the recrystallization temperature then it is termed as Hot rolled and if ...

Get Price -

prefix Overview of our separators · Christian Pfeiffer

For combined roller press and ball mill grinding systems. The TFS is a dynamic separator working together with a static separator in a so called DSS (Dynamic Static Separator) system. These separators were specially designed for the use in combined grinding systems which .

Get Price -

API Reference

Sense HAT API Reference LED Matrix set_rotation . If you're using the Pi upside down or sideways you can use this function to correct the orientation of the image being shown. Parameter Type Valid values Explanation; r: Integer: 0 90 180 270: The angle to rotate the LED matrix though. 0 is with the Raspberry Pi HDMI port facing downwards. redraw: Boolean: True False: Whether or not to redraw ...

Get Price -

Patents Assigned to KHD Humboldt Wedag

· Abstract: A method for regulating the roll gap pressure of a roller press and a corresponding roller press. The roll gap pressure is regulated dependent on at least one oscillating movement that is measured on the roller press. This has the advantage that the roller press can always be operated at the maximum roller press efficiency without the roller press reaching the overload .

Get Price -

RollerPress

Raw Material forgings Step Forged Steel Bars and Rings, a Forging Ratio of I . 35 ... Roller Press and deep hole drilling for water cooling. ... TS6 KHD Roller Core 1,700 x 1,400 TS6 KHD Roller Core 1,700 x 1,400 LP TS6 KHD Roller Core 1,700 x 1,400 LP TS6 KHD

Get Price -

IELTS DATA Reading Test 17 The History of Papermaking ...

The first reference to a paper mill in the United Kingdom was in a book printed by Wynken de Worde in about 1495. This mill belonged to a certain John Tate and was near Hertford. Other early mills included one at Dartford, owned by Sir John Speilman, who was granted special privileges for the collection of rags by Queen Elizabeth and one built in Buckingham shire before the end of the ...

Get Price -

AVIC International Beijing Company Limited

KHD provides a wide range of products and services including preheater, calciner, 3tier and 2tier kiln, 4channel burner, Vseparator, dynamic separator, grate cooler, roller press, ball mill, SIMULEX® simulation and training system, and PYROEXPERT® and MILLEXPERT® automation system.

Get Price -

Primetals Technologies to supply steel plate finishing ...

Reference number: PRen Page 1/2 Press London, September 16, 2021 Primetals Technologies to supply steel plate finishing rolling mill for Kakogawa Works of Kobe Steel in Japan · Finishing rolling mill with improved rigidity · Contributes to strengthening the product supply system with more stable quality and delivery time

Get Price -

PERPUSTAKAAN UMP 1111

used in the vertical roller mill. Being of the segmented type the wear liners can be hardfaced numerous times throughout their life. Advantages ]Appliion advantages Proven commercially, the vertical roller mill is the premier roller mill for finish grinding of portland cement, slag and blended cements. With a 3045% reduction in the

Get Price -

POLYCOM highpressure grinding roll

POLYCOM® highpressure grinding roll The reliable and energysaving grinding system One of the principal reasons for the outstanding success of the highpressure grinding roll in the cement industry is its low power requirement. Today, this mill is employed all around the world for the grinding of cement raw material, cement clinker and granulated blast furnace slag. For new plants, the ...

Get Price -

Khd Humboldt Coal Mill

Khd Raw Mill With Roller Press Reference. Rolling bearings in khd humboldt wedag press over conventional, include a considerably higher efficiency and a higher humboldt wedag roller presses courtesy of price and support online khd humboldt coal mill raw mill 42.

Get Price -

KHD reports a rise in 2010 orders

· In September 2010 KHD signed an order of €85m for 2 x 10,000 kiln lines with Indian cement producer UltraTech Cement Ltd., who is one of the largest cement producers in the world and the largest in India. At the time of signing KHD was the only supplier in India with a reference plant for 10,000tpd of clinker in operation. KHD's efficient ...

Get Price -

khd raw mill with roller press reference

KHD wins an order for a 5000 tpd production line in, Comflex raw grinding system incorporating a KHD RPS18 Roller Press,, roller type clinker crusher KHD Ball Mill system for, .

Get Price -

Used Khd Ball Mill

· Khd raw mill with roller press reference. ball mill drive for existing ball mill and new feeding equipment for raw . a subsidiary of khd humboldt wedag . two roller press rpm . get price and support online how to do balancing of cement mill separator. the extensive range of polysius roller mills provides . roller mill for cement raw material . khd is a global leader in.

Get Price -

ABB Ability Advanced Process Control for metals

Raw material grinding was installed on a grinding circuit that included a rollerpress with static Vseparator and single chamber ball mill, improving control performance with a 4% productivity increase, 3% energy savings and 60% reduction of returns standard deviation.

Get Price -

prefix Overview of our separators · Christian Pfeiffer

For combined roller press and ball mill grinding systems. The TFS is a dynamic separator working together with a static separator in a so called DSS (Dynamic Static Separator) system. These separators were specially designed for the use in combined grinding systems which consist of roller press and ball mill.

Get Price -

IMPROVING THERMAL AND ELECTRIC ENERGY EFFICIENCY AT CEMENT ...

Optimizing the Operation of a Cement Mill ..... 30 HighPressure Roller Press as a Pregrinding Step for Ball Mills ..... 31 Improved Grinding Media for Ball Mills ..... 32 HighEfficiency Classifiers

Get Price -

Home

· Innovative solutions for the cement industry made in Germany. IKN offers what it takes to build and operate profitable cement plants.

Get Price